What Is Balanced Drilling? Key Principles and Benefits

In oil and gas exploration, the way a well is drilled can make or break the project, affecting everything from speed and safety to the final cost. Balanced drilling has recently moved to the spotlight because it controls underground pressure almost perfectly, reducing the risk of blowouts or lost circulation. So, what exactly is balanced drilling, and how does it stack up against older methods like underbalanced and overbalanced drilling?

What Is Balanced Drilling?

Balanced drilling is a wellbore-management technique in which the weight of the drilling fluid is carefully adjusted to match the in-situ pressure of the surrounding rock. When this balance is achieved, the wellbore sits in a state of near-neutral pressure, so that neither formation fluids are drawn in nor the drilling mud is forced into the reservoir, thus shielding the pay zone from harm and lowering the chances of a kick.

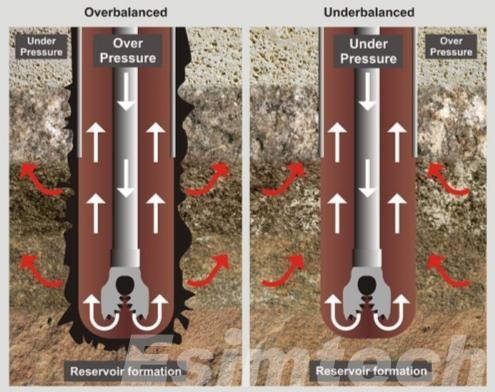

The strategy sits between two more extreme methods: underbalanced drilling, where the column pressure is kept deliberately low, and overbalanced drilling, where mud weight is raised above pore pressure. By operating in this measured middle ground, balanced drilling aims to capture the safety gains of each technique while side-stepping the hazards they can bring, giving teams a more stable environment as the bit advances.

Keeping that fragile pressure balance in place demands tight control of fluid density, round-the-clock pressure checks, and fresh data on how the rock pops and reacts. Providers now rely on downhole sensors that stream numbers back in real time, plus managed-pressure-drilling rigs outfitted with valve and choke arrays that dial in the exact setpoint.

Because of this careful setup, balanced drilling shines in formations known to slump, fault, or bleed away, such as depleted reservoirs or blocks stitched with natural fractures. By dodging the pressure spikes that can ruin hole integrity or snarl operations, the technique boosts safety, protects valuable rock, and often trims hours, risk, and costs.

Key Principles of Balanced Drilling

Balanced drilling works by matching the weight of the drilling fluid to the rocks natural pressure. To get that match, crews focus on four simple actions:

- Dynamic Pressure Management: Drillers constantly change mud weight and pump speed as new data comes in. Sensors deep in the hole send live pressure readings, so the crew can tweak the fluids weight only when needed. Keeping pressure this steady keeps mud from rushing in or leaking out.

- Engineered Drilling Fluids: Mud recipe is designed with just the right density, thickness, and leak-off rate. With careful mixing, the fluid can hold up the well without blocking cuttings or cracking the rock.

- Integrated Formation Evaluation: Before work starts, detailed maps and tests-wireline pressure logs, for example-show the highs and lows of pore and fracture pressures. That intel sets the mud weight and guides quick changes when the drill moves into new layers.

- Advanced Monitoring & Control Systems: A full set of tools, like measurement-while-drilling (MWD) sensors and accurate flow meters, sends real-time data up to a single control unit. Built-in alerts and quick feedback let the drilling crew react fast to any pressure change, which helps keep the well secure and cuts wasted time.

When these ideas work together, they create balanced drilling. That means the team enjoys tighter pressure control, better safety, and faster, smoother drilling.

Benefits of Balanced Drilling

Balanced drilling blends advanced pressure management and real-time monitoring to boost performance, trim costs, and protect personnel, making it the method of choice in challenging fields.

Enhanced Reservoir Integrity

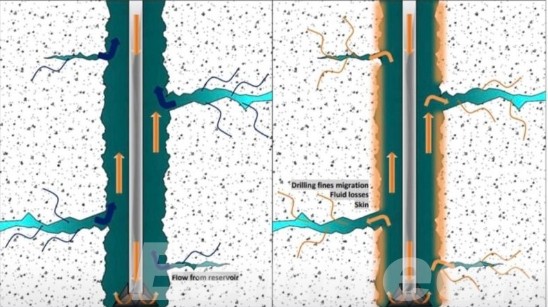

By holding mud density at the pore pressure line, balanced drilling blocks filtrate invasion that can clog rock pores. This preservation of permeability boosts initial flow and steadies long-term recovery, protecting the reservoir’s economic value.

Superior Wellbore Stability

With formation and hydrostatic pressures kept in check, balanced drilling limits fracturing above and collapse below. Operators face far fewer stuck-pipe events or bent casing, trimming non-productive time, and the rig-hours that drive up budgets.

Elevated Safety and Well Control

Smaller pressure windows all but eliminate kicks and blowouts caused by sudden inflow. Coupled with continuous monitoring and preset alarms, the method turns a potential crisis into manageable data, shielding crews and equipment.

Reduced Fluid Loss and Environmental Impact

Underbalanced sweeps often bleed mud into fractured zones, forcing expensive additives and raising disposal burdens. Balanced drilling cuts these losses, slashing material costs and softening the project’s ecological footprint.

Optimized Drilling Economics

While the method depends on advanced sensors and careful coordination, its gains are clear: fewer sidetracks, shorter rig freeze periods, and less costly fixes after the fact. Taken together, these savings can trim the total drilling budget by an estimated 10 to 15 percent.

Flexibility in Challenging Formations

Balanced drilling easily adjusts to depleted reservoirs, naturally fractured rock, or high-pressure-high-temperature HPHT zones. Because it keeps pressures steady within narrow margins, the approach shines in unconventional plays and aging fields where even small upsets can damage formation integrity.

Applications of Balanced Drilling

Balanced drilling shines in tricky wells where tight pressure control really matters. By guarding against formation damage, cutting safety risks, and keeping the hole in shape, operators choose it for many delicate jobs.

1. Depleted Reservoirs

In older fields, pressure often sits well below normal levels. Going overboard with heavy mud in those areas can drain even more fluid and hurt the rock. Balanced drilling holds pressure steady, slowing further loss and helping the reservoir stay productive.

2. Naturally Fractured Formations

Rock that cracks naturally is always a lost-circulation nightmare. Forceful mud can wedge into those cracks and disappear, wasting time and money. Balanced drilling keeps pressure equal, so mud is less likely to leak and the job moves faster.

3. Unstable or Sensitive Formations

Weak rock- like shale, salt, or loose sand-can easily cave in when the wrong pressure hits. An uneven push can crush the hole or wash it away, causing serious delays. Balanced drilling calms that pressure swing, letting crews move through soft zones more safely and quickly.

4. High-Pressure, High-Temperature (HPHT) Wells

Working in a high-pressure, high-temperature (HPHT) well means even small mistakes can turn deadly. By using balanced drilling, crews gain tighter control over pressure up and down the hole, cutting the chances of sudden gas kicks and blowouts.

5. Workovers and Sidetracks

When operators go back into an old well for a workover, a sidetrack, or a re-entry, they still want to keep the casing where it is. Balanced drilling lets them feed tools in smoothly, so the original wellbore stays sealed and all productive zones stay protected.

Taken together, these examples show that balanced drilling is both dependable and flexible, shining in jobs where formations are soft, pressure jumps are hard to predict, or worker safety has to come first.

Balanced Drilling vs. Underbalanced and Overbalanced Techniques

Effective drilling requires close control of the pressure difference between the wellbore and the surrounding rock, an imbalance that can jeopardize safety, slow progress, and damage the reservoir. Engineers typically choose one of three principal techniques to manage that gap:

- Underbalanced drilling (UBD) keeps the fluid-column pressure below the rock-pressure gradient, inviting formation fluids-oil, gas, or water-into the wellbore as the bit advances. That inflow can enhance penetration speed and yield early reservoir data. The trade-off is a higher chance of uncontrolled kicks or blowouts, so UBD mandates extra vigilance in blowout-prevention equipment and crew training.

- Balanced drilling maintains the mud pressure at an exact match to the formation gradient, preventing either loss of drilling fluid into the rock or influx from the rock into the borehole. Because both forces cancel, wellbore walls stay stable and the reservoir remains relatively undisturbed. Achieving that equilibrium does demand continual, precise monitoring of pressure and mud properties, making real-time data the heartbeat of the operation.

- Overbalanced drilling (OBD) intentionally maintains mud density above existing pore pressure. By doing so, the column pressure counters subsurface fluids, making well-control responses more straightforward for drill crews. This operational cushion, however, carries significant trade-offs: excess hydrostatic head can seep into rock, leading to lost circulation, impairing reservoir integrity, and ultimately curtailing future production rates.

| Aspect | Underbalanced Drilling | Balanced Drilling | Overbalanced Drilling |

| Wellbore vs. Formation Pressure | Lower | Equal | Higher |

| Key Advantages | • Faster ROP & early formation evaluation • Reduced differential sticking | • Optimal wellbore stability • Minimal formation damage • Lower NPT | • Simplified well control • Wellbore remains fluid-packed |

| Key Drawbacks | • High risk of influx/blowouts • Requires advanced well control | • Demands precise pressure control • Requires continuous monitoring | • Fluid invasion & lost circulation • Potential reservoir impairment |

This comparison makes it clear that balanced drilling offers a middle path—combining the safety of overbalanced methods with the production benefits of underbalanced approaches, albeit with the need for meticulous pressure management.

Summary

Balanced drilling is a safe and efficient way to keep the pressure inside the well equal to the pressure of the surrounding rock. By carefully managing this pressure, the method helps stop the hole from collapsing, cuts down on accidents , and makes drilling faster. Although overbalanced and underbalanced techniques work in certain situations, balanced drilling is still the go-to choice for most everyday rigs.

To get the best results, drilling crews need to watch the pressure and density of the drilling mud in real time and tweak its weight whenever the ground conditions change.