Open Hole vs. Cased Hole Well Logging: Which One to Choose

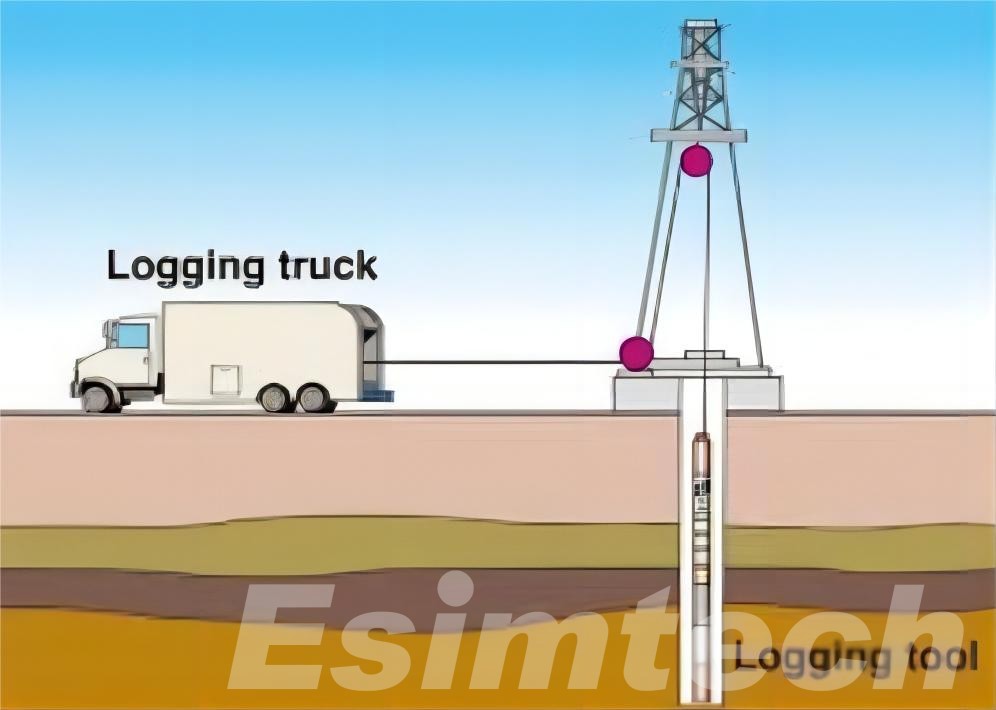

Well logging is a critical process in the oil and gas industry. It gives valuable information about subsurface formations. Two main methods for well logging include open hole logging and cased hole logging, each of which serve different functions in various stages of well construction and is selected according to the operating stage of the well and the type of data required. Knowing their advantages, limitations, and differences can help engineers make informed choices for evaluating reservoirs and well integrity.

What is Open Hole Logging

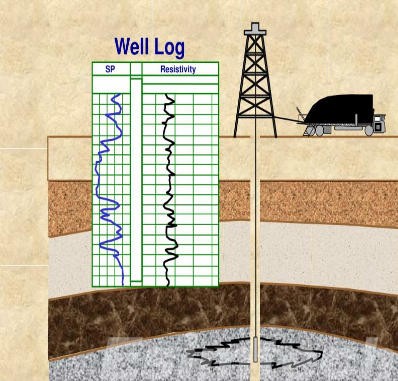

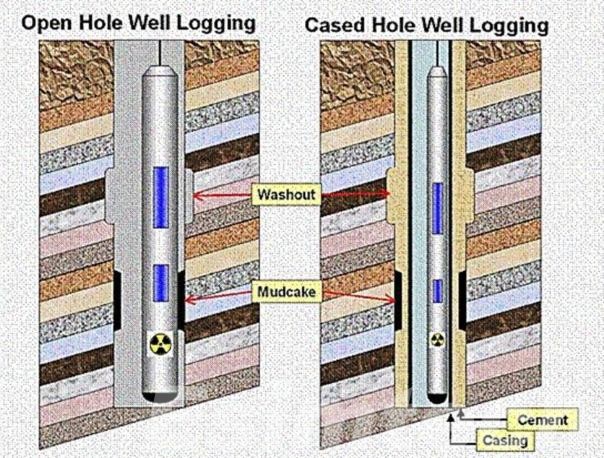

The open hole logging is a technique employed for exploration and oil drilling in which measurement instruments are dropped into the wellbore before the wellbore is lined by cement or casing. This method keeps continuous and precise information about the geological structures that are drilled by the drill bit and provides vital information on the characteristics of the formation such as porosity and resistivity, density and radioactivity that is natural.

The purpose of open hole logs is to assess the subsurface geology, and to determine the amount, quality and the production capability of hydrocarbons.

Advantages

- Direct Formation Access: Since there isn’t any cement or casing between both the instrument and rock This makes the measurements more precise and less influenced by interference.

- Comprehensive Data Collection: Multiple parameters of formation can be measured simultaneously including lithology, porosity indicators of permeability and saturation.

- Supports Reservoir Evaluation: The data aids in determining the hydrocarbon bearing zones as well as estimating reserves and formulating strategies for completion.

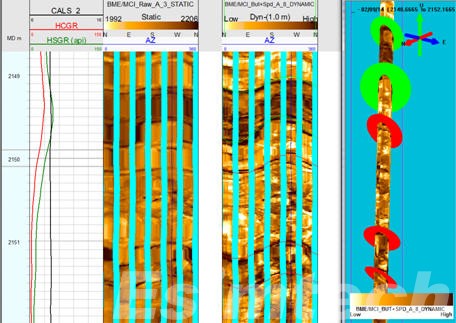

- Detects Fractures and Bedding Planes: Open hole logs are high-resolution imagery, which assists with recognizing natural fractures as well as dips that form.

- Cost Efficiency: Logging before casing eliminates the expense of logging through steel casings or perforation problems.

Limitations

- Wellbore Instability: In certain types of formations, the hole can be able to cave in or collapse before or during the logging process, restricting access to or damaging tools.

- Limited Logging Time: The open hole’s environment might not be stable over long time periods, which is why log operations need to be finished swiftly.

- Fluid Invasion Effects: Fluids and drilling muds can penetrate the formation, altering the properties of the formation (especially resistance).

- Tool Sticking Risks: Without casings the logging equipment could get stuck in a variety of collapsing or irregular sections of borehole.

- Environmental Sensitivity: A buildup of mudcakes and borehole washouts can affect the accuracy of readings.

Common Applications

- Hydrocarbon Exploration and Appraisal: The process is used to find potential gas and oil zones, and to estimate the size of reservoirs and efficiency.

- Formation Evaluation: Helps petrophysicists and geologists comprehend the rock types as well as pore spaces and the content of fluids.

- Well Placement: Helps with geosteering and horizontal drill by providing real-time formation information.

- Reservoir Characterization: Assists with designing and implementing simulations of reservoirs for development planning.

- Formation Pressure and Temperature Monitoring: Allows pre-casing of measurements of temperature and pressure gradients.

What is Cased Hole Logging

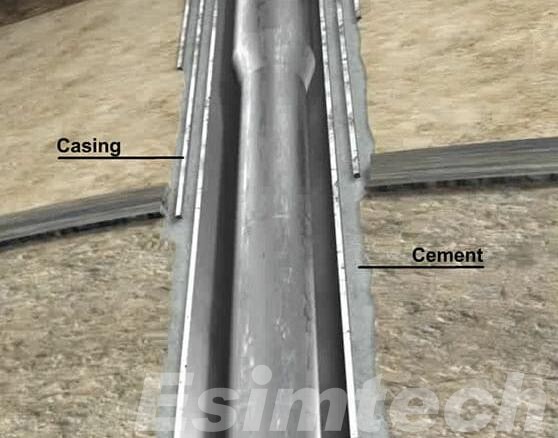

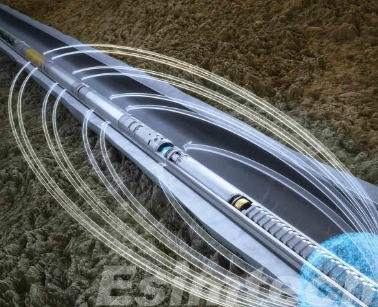

Cased hole logging is a well logging technique that is conducted after the wellbore is filled with steel cabling and bonded to the formation. In contrast to open hole logging where the instruments interact directly in the formation the cased hole logging tools monitor the formation’s fluid properties and structure by observing the casing. This technique is extensively used to monitor production, evaluate the changes in reservoir over time, and for guiding the intervention process throughout the lifetime of the well.

Advantages

- Wellbore Stability: Logging through casing solves problems caused by borehole collapse or instability, which allows for more secure and controlled operations.

- Long-Term Monitoring: Logs from the cased hole can be repeated throughout the duration of the well’s existence to track the performance of production and reservoir change.

- Targeted Evaluation: It permits a precise assessment of particular zones, especially in wells with multiple production intervals or in recompletion scenarios.

- Accurate Fluid Identification: Instruments like pulsed neutron logs enable the identification of the nature and flow of fluids behind the casing (e.g., oil, gas, water).

- Supports Well Integrity Monitoring: Cased holes logging helps identify corrosion in the casing and cement bond quality and mechanical damage, which is essential for the integrity of wells.

Limitations

- Reduced Formation Sensitivity: The cement and casing may distort or weaken signals, which can result in less precise readings than open hole logs.

- Tool Limitations: Certain measures (e.g., resistivity, resistance, or detailed logs of lithology) aren’t feasible or reliable with casing.

- Higher Equipment Requirements: Innovative tools like Gamma-ray spectrometry or pulsed neutrons are frequently required to increase the cost of operations.

- Interpretation Complexity: Data processing and interpretation require sophisticated models and calibrations due to the effects of casing.

- Limited Logging Before Completion: Important formation data could be lost if the open hole logs were not conducted before casing.

Common Applications

- Production Logging: Analyzes flow rates, locates zones of production, and identifies gas or water leaks in wells that are producing.

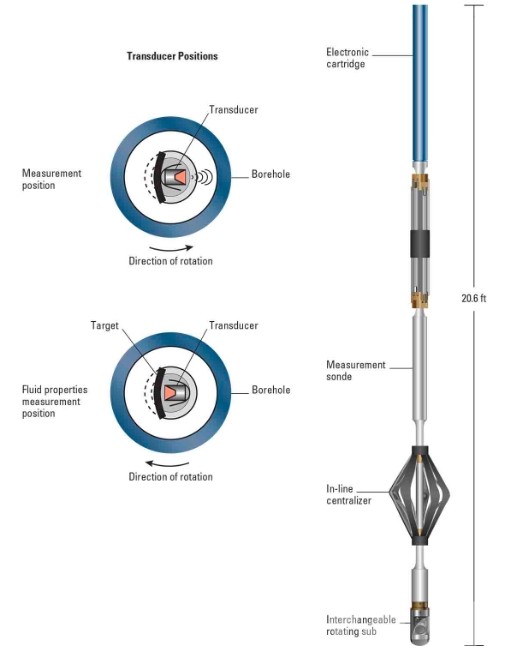

- Cement Bond Logging (CBL): Examine the quality of the cement work between the formation and the casing to ensure isolation of the zones.

- Perforation Zone Selection: The guideline for selecting the best intervals for perforation of completed wells.

- Reservoir Monitoring: Useful to track the changes in pressure and saturation of reservoirs as time passes, which aids in the improvement of recovery planning.

- Well Integrity Evaluation: The system detects corrosion, deformation of the casing or leaks to ensure an efficient and safe operation of the well.

Key Differences Between Open Hole and Cased Hole Logging

| Aspect | Open Hole Logging | Cased Hole Logging |

| Timing | The drilling is performed after the drilling process and prior to casing | This is done after the cementing and casing are complete |

| Formation Access | Direct access to the form | The formation is separated by casing and cement |

| Measurement Accuracy | Generally, the price is higher due to free access | The difference is slight due to the cement and casing interference |

| Main Objectives | Assess the properties of formation prior to the completion | Check for well-being and evaluate the integrity of the program after completion |

| Common Tools Used | Gamma ray, resistivity, density, neutron, sonic, NMR | Cement bond logs, pulsed neutron production tools for logging |

| Risk Level | Higher (risk of sticking tool and borehole collapse) | Lower (stable borehole conditions because of casing) |

| Data Collected | Porosity, liquid type, and saturation | Production profiling, cement integrity Monitoring saturation |

| Formation Imaging | High-resolution imaging possible | Limitation in imaging capabilities because of the casing |

| Operational Flexibility | Limited by borehole conditions and duration. | More flexibility to monitor the well throughout the well |

| Primary Application | Exploration and evaluation of the reservoir’s initial state | Production optimization and well diagnostics |

Simulations used for Open Hole vs. Cased Hole Well Logging

This chart demonstrates the way that well logging simulation tools are designed to deal with the specific technical difficulties and goals of both open hole and cased hole logging.

| Simulation Aspect | Open Hole Logging | Cased Hole Logging |

| Tool Response Modeling | Simulates interactions between tools and the formation fluids, rocks, and other materials. | Simulates signal attenuation by the casing and cement |

| Borehole Environment Simulation | Models the effects of mud intrusion as well as washouts and borehole geometry | Models of cement the quality of bonds along with casing eccentricity, as well as annular fluids |

| Formation Property Prediction | Predicts porosity and permeability the lithology, and saturation | The estimation of changes in saturation with time using pulsed neutron devices |

| Pre-Job Planning | Improves the selection of tools along with depth intervals runs with open holes | Production well logging stimulation helps to select the best logging tools that are appropriate for the specific zones |

| Imaging Simulation | Examines the resolution of borehole imaging in different kinds of lithologies | Limited due to casing primarily to be used in cement evaluation simulations |

| Sensitivity Analysis | Testing the influence of heterogeneity in formation on log response | Analyzes the impact of the thickness of the casing and the presence of cement flaws on logs |

| Operational Risk Assessment | Examine the risks of sticking tools or collapsing in areas of instability | Simulates the conveyance of tools and wellbore access via casing or tubing |

| Training and Visualization | Open hole well logging simulators Utilized in virtual training to better understand open hole tool behavior | Assists in the interpretation of production logs and well integrity training |

Which Type Should You Use Between Open Hole and Cased Hole Well Logging

The choice between open hole and cased hole logging is based on the particular goals of your well operation, the timing within the well’s lifecycle, and the geological conditions encountered.

Use Open Hole Logging for Formation Evaluation

Logging through the open hole is the most preferred option during the appraisal and exploration phases of the drilling process. If the main objective is to determine the reservoir’s petrophysical characteristics, such as porosity, lithology, saturation and permeability, then the use of open hole logging is vital. It is the most precise and exact analysis of the reservoir because there isn’t a cement or casing to affect the logging instruments. This information is crucial in determining whether hydrocarbons are present as well as estimating reserves and deciding whether to go with the well’s the completion of the project or abandon it.

Open hole well logging is perfect when precise formation imaging is needed. Equipment like borehole imaging and NMR (NMR) sensors work better in non-cased environments. However open hole logging must be performed promptly after drilling to avoid issues due the borehole’s instability.

Use Cased Hole Logging for Monitoring and Maintenance

The method of cased hole well logging is best suitable for wells that are either in production or have been completed. If your goal is to determine the quality of cement or to detect damage to the casing or monitor the performance of production, or assess fluid movement behind the casing, then cased hole logs are the right method. It permits engineers to monitor the well’s integrity and changes in reservoir throughout time without reopening the formation.

Cased hole logging is beneficial in mature fields where reservoir management over the long term is essential. With instruments designed to use steel casings and cement cased hole logging, it allows continuous monitoring of water saturation, hydrocarbon breakthrough, and the effectiveness of injection in the process of Enhanced Oil Recovery (EOR) operations.

Summary

- For the initial evaluation of formation and for planning, open hole well flogging offers superior precision and detail.

- For operations-related monitoring, diagnostics and the analysis of production, cased hole well logging gives you secure and safe access to data from the subsurface throughout the lifetime of the well.

- In many cases, a combination of both methods is employed. Open hole logs provide the reservoir’s baseline data and cased hole logs are used to assess the performance of wells and guide future intervention.

Final Thoughts

Both open and cased hole well logging serve vital functions in the lifecycle of a well. A comprehensive knowledge about the strengths and drawbacks of each method allows geoscientists and engineers to make informed decisions to improve well performance and safety. In modern reservoir management, the combination of both techniques is frequently employed to create a complete picture of subsurface conditions.