Integration of Snubbing Units in Plug and Abandonment (P&A)

The integration of snubbing units in Plug and Abandonment (P&A) operations is increasingly becoming a strategic choice for well decommission, particularly in high-pressure or complex conditions. Snubbing units allow the handling of live wells, without killing them, offering a safe and effective method for sealing and isolating the end-of-life wells. This article focuses on the function of snubbing units in P&A, the benefits they provide, their key operational considerations, and the use of simulation technology to optimize the process.

Understanding Plug and Abandonment (P&A)

Plug and Abandonment is the procedure of permanently decommissioning wells for oil or gas that are not economically feasible or have reached the point of no return. The goal is to ensure long-term integrity of the well and safety for the environment by putting an array of cement and mechanical plugs into the wellbore to separate the formations that contain hydrocarbons.

For a long time, P&A operations have relied on rigs that were conventional or coiled tubing units. However, wells that have high pressure, complex completions or hydrocarbons that are live pose challenges and drawbacks that can be better managed by Snubbing units.

What are Snubbing Units

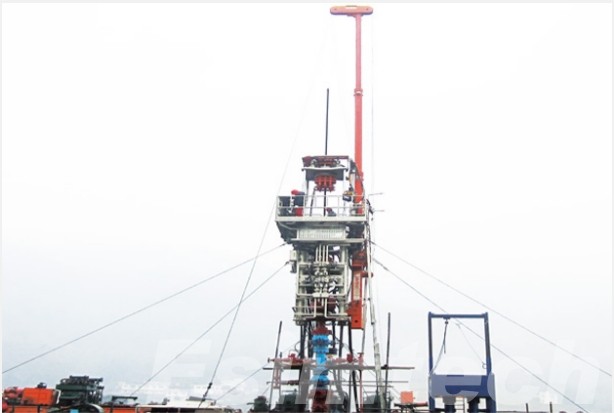

Snubbing units are hydraulic workover systems that are capable of pushing (snubbing) or pulling tubulars out and in of wells in live wells, which are pressured wells without the requirement for killing fluids. They are available in different configurations, including rig assist and standalone units. They can be equipped to handle high-pressure and high-temperature (HPHT) environments.

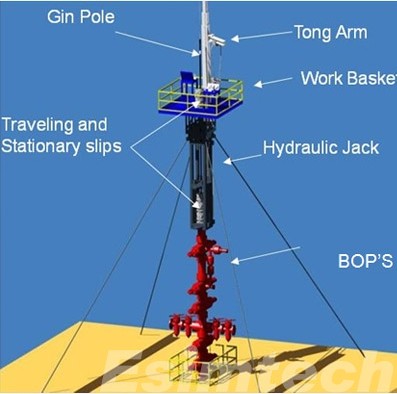

Key Components

| Component | Function | Importance in P&A Operations |

| Snubbing Jack | It uses hydraulic force to pull or push pipe inside or out of an existing well. | Allows controlled tubular movement under pressure. |

| Hydraulic Power Unit (HPU) | Provides hydraulic power to operate the snubbing jack as well as other tools. | It ensures the safety and consistency of the whole snubbing system. |

| Blowout Preventer (BOP) Stack | Controls the well by sealing the well when pipe movement occurs. | Essential for pressure control and emergency shut-down scenarios. |

| Work Basket / Platform | Tools and personnel support above the stack that is snubbing. | It provides a safe work area for the operators in the live well’s intervention. |

| Pipe Handling System | Stabilizes tubulars and guides them when they are inserted and removed. | It ensures a precise alignment and minimizes the chance of tubular or tool damage. |

| Slips (Traveling & Stationary) | Pipes are gripped to regulate the vertical movement of the pipe during operation. | Stops tubular fall as well as unintentional movement when under loads. |

| Control Panel | Interfaces with hydraulic systems as well as pressure monitoring equipment. | It allows operators to control system functions and track pressure levels. |

| Accumulator System | It stores pressurized fluid for quick actuators of BOPs as well as hydraulic tools. | Rapid response capability in the control of pressure events. |

| Lubricator / Stripping Head | Allows pipe to move without compromising pressure. | It is essential to run tubulars or tools in the well with no losing fluid. |

Key Advantages of Integrating Snubbing Units in Plug and Abandonment(P&A)

1. Enables Live Well Operations

Snubbing unit is uniquely capable of handling tubulars inside the pressurized and outside of wells. Operators can carry out the majority of P&A tasks like lifting tubings, putting plugs in, and cleaning the wellbore, without destroying the well. The pressure of working under does not just reduce the risks that are associated with high kill fluids, but also preserves the integrity of the structure of the well, especially in high-pressure or damaged wells.

2. Reduces Risk of Formation Damage

Traditional methods of killing wells include introducing a kill-weight mud to the wellbore. This can harm productive formations, specifically in older wells that have poor zonal isolation. The snubbing method eliminates this requirement and stops any introduction of fluids that can cause damage to the reservoir and differential sticking, as well as fluid movement. In addition, maintaining the pressure of the reservoir throughout P&A will result in a cleaner and more controlled process of abandonment.

3. Improves Operational Safety

Safety is a crucial element of any P&A operation. Snubbing equipment is equipped with the latest Blowout Prevention (BOP) stacks as well as multiple Pressure control devices. This enables operators to control the fluctuating well pressures and conditions in real-time. The design and structure of snubbing operations puts well control at the top of the list which significantly lowers the risk of blowouts and hazardous fluid leaks.

4. Reduces Environmental Impact

The prevention of kill fluids not just ensures the safety of the formation, it also lowers the chance of environmental contamination due to leaks or spills. Snubbing units require less consumables, and produce less waste than traditional abandonment techniques based on rigs. In addition, the smaller footprint of the surface area of standalone snubbing units helps in reducing the environmental impact both in onshore and offshore environments.

5. Increases Efficiency and Lower Costs

Snubbing units generally require less time to set up and run than traditional drilling or workover rigs. They have a smaller footprint, and quicker mobilization make them perfect for fast-turnaround P&A campaigns. This is particularly advantageous for offshore platforms as space is scarce and rig time can be expensive. Operators can finish abandonment operations faster, reducing the total cost of projects and minimizing non-productive times (NPT).

6. Provides Flexibility for Complex Wells

A lot of wells that are mature have unique issues, such as stuck tubulars, casings that are deformed or a lack of pressure isolation. Snubbing units are extremely flexible, able to handle various tubing sizes and complicated geometries for downholes. The ability to operate through barriers that are multi-stage and reach difficult zones makes them perfect for complicated abandonment techniques which require precision and control.

7. Ensures Compliance with Regulatory Standards

Modern abandonment regulations require strict standards for permanent barrier installation and verification. Snubbing units allow for the precise implementation of these regulations in live well conditions, which allows the precise placement of cement blocks as well as mechanical packers and various integrity barriers. This will ensure full compliance with the regulations while ensuring well-controlled throughout the entire process.

Applications of Snubbing Units in Plug and Abandonment(P&A)

| Application | Description | Benefit |

| Tubing Retrieval Under Pressure | Remove production tubing from the live well. | Keeps the well-controlled level in check without having to kill fluids. |

| Setting Mechanical Bridge Plugs | Insertion of plugs and packers in live-well conditions. | This ensures precise placement and also preserves the pressure in the wellbore. |

| Wellbore Cleanout Operations | The removal of scale, debris or buildup of fluid in pressurized wells. | Prepares the wellbore for barrier installation, without introducing foreign fluids. |

| Section Milling | Milling sections of casing for the installation of barriers or zones of isolation. | Allows for complex downhole drilling while ensuring the pressure level. |

| Casing and Tubing Cutting | Removal and cutting of damaged or unneeded pipe under pressure. | Provides cleaner and safer removal methods in tough conditions. |

| Installation of Cement Plugs | The installation of cement barriers is done under live-well conditions. | This prevents fluid movement between zones and ensures the integrity of the plug. |

| Hydraulic Fishing Operations | Retrieval of lost or stuck downhole equipment without destroying the well. | Reduces downtime and increases Recovery success rates. |

| Well Integrity Verification Tasks | Pressure testing, log keeping and mechanical inspections while keeping good pressure. | Helps with the regulatory compliance and barriers certification. |

Operational Considerations in Integrating Snubbing Units in Plug and Abandonment(P&A)

A successful integration of the snubbing unit into plug and abandonment, depends on careful planning and adhering to particular operational considerations. These factors make sure that this process remains safe, efficient and in compliance with all regulatory and technical requirements.

- Well Integrity Assessment and Planning

Before installing a snubbing system it is vital to conduct an extensive check on the well integrity. This involves assessing the tubing and casing conditions and annular pressure, prior interventions, as well as whether hydrocarbons are present. Understanding the structure as well as its pressure profiles is essential in determining a snubbing procedure which avoids problems such as tubing collapse or failure of the barrier. Integration planning should consider the precise procedures for removing downhole components and making plugs in pressure.

- Pressure Control System Compatibility

The most crucial operational elements is to ensure ability of the pressure-control equipment with the wellhead that is in place and the BOP stack. The snubbing system is required to be outfitted with the appropriate calibrated annular and ram preventers as well as lubricators and stripping heads that can manage the maximum surface pressure. In addition, the stack-up must be designed to allow for effective deployment of plugs and tools, and to maintain pressure control throughout the entire process.

- Selection of Snubbing Unit Type

The choice between a rig-assist or a stand-alone device is dependent on the conditions and the operational objectives. Snubbing units that stand alone are great for offshore or remote wells that have limited space however rig-assist designs are more suited to land-based operations that incorporate support for rigs. The unit you choose to use must be sized to the expected tubular load and pressures, as well as the operating depths.

- Personnel Competency and Training

Snubbing operations rely on live well interventions and are high-risk. Thus, trained and skilled personnel are crucial. They must be knowledgeable about pressure control as well as hydraulic mechanics and emergency responses, and live-well procedure. Training and simulation exercises are frequently required to train operators for the rigors of dynamic downhole situations, such as unexpected pressure surges, or tool malfunctions.

- Barrier Management and Verification

Abandonment operations require the construction of permanent barriers to protect hydrocarbon zones. If a snubbing device is used that includes cement and mechanical plugs must be tested and set in live well conditions. Operators need to have a clearly defined barrier plan that is compatible with local regulatory frameworks, such as pressure testing, tagging and logging in order to ensure their location and quality.

- Operational Sequencing and Risk Mitigation

The order in which tasks are completed–such as the pull of tubings, plug turning and section milling – must be carefully designed to reduce the risk of downtime and risks. Every step must include an assessment of risk along with mitigation measures. For example, if the tubing has become corroded or stuck, the tools for contingency fishing and procedures should be planned out. Multiple control systems, as well as real-time monitoring must also be available to react promptly to any abnormalities.

- Logistics, Footprint, and Equipment Handling

In particular, in off-shore or space-limited areas it is essential that the footprint and physical dimensions of the device and the equipment that it is connected to must be taken into consideration. Calculating load, access to the crane and connectivity to platforms is crucial. Furthermore the availability of hydraulic fluids, power and spare parts must be secured in order to avoid interruptions and delays in the process.

- Regulatory Compliance and Documentation

In the end, integrating snubbing devices in P&A must be compatible with the legal framework of the area of jurisdiction. Authorities might require specific documentation, such as well integrity reports plug verification logs and pressure test reports. A clear and accurate process and documentation are vital to obtain an approval from the authorities, passing through audits and proving that the process of abandoning was conducted in compliance to environmental and safety standards.

How Simulation Technology is Used for Incorporating Snubbing Units into Plug and Abandonment (P&A)

Simulation technology provides a virtual setting to design, test and optimize each aspect of the snubbing-enabled P&A process. From pre-job planning to real-time training and risk mitigation, simulation tools can ensure that the operation is carried out efficiently and safely, even in the most challenging environments.

Virtual Planning of Snubbing Operations

Simulation software lets engineers create a model of the specific conditions for a well and then test the complete sequence of P&A procedures prior to deploying equipment on the field. By putting in wellbore geometry the pressure profile, characteristics of fluids and snubbing unit specifications planners can build precise digital copies of the desired wells. The virtual snubbing simulation helps determine the best snubbing force and tool string configurations and operating sequences. Simulations, for instance, can determine how tubulars react to pull and push forces when retrieving them and the way pressure differentials work when plugs are placed, all without exposing the crew to live well dangers.

Pressure Control and Wellbore Integrity Modeling

One of the biggest problems for snubbing-based P&A is ensuring that pressure control remains in place. Simulation tools are able to simulate dynamic pressure behaviour within the wellbore during live operations, which can help engineers to plan the placement of barriers and manage gas expansion and prevent unintentional inflows. The models also take into account fluctuations in temperature and pressure which could impact the quality of the casing, plugs and packers. Advanced simulators simulate fluid movement within the annulus and tubing based on tool movements, and ensure that the barrier strategy is tested prior to implementation.

Training for Snubbing Crews

Snubbing tasks require an advanced level of technological competence and rapid decision-making when under pressure. Oil and gas simulation technology allows for immersive, realistic training for field staff. By using virtual snubbing equipment and live-well simulation platforms, workers are able to practice tasks like tubular handling, rig-up, pressure changes, and emergency actions. Training modules for crews improve performance, enhance the best practices, and help prepare the team for uncommon but risky events such as gasoline kicks, and BOP malfunctions.

Real-Time Decision Support During Operations

In some of the most advanced applications, simulation systems are often linked to live feeds of data in the real world. The snubbing simulator gives real-time assistance during the snubbing process. For example, if an unexpected pressure increases are observed at the surface of sensors, the simulation can be used to determine how different interventions, such as reducing pipe movement or altering the density of fluids–will affect downhole conditions. It is a “what-if” analysis provides operators with a greater awareness of their surroundings and decreases the chance of unplanned events.

Contingency Planning and Risk Assessment

Simulation tools are extremely useful in identifying and preparing for the possibility of operational risks. They aid operators to conduct thorough failure-mode studies, like what could happen when tubulars get stuck, plugs are set improperly, or annular pressure suddenly increases. Teams are able to create contingency plans, evaluate different emergency procedures, and make sure backup equipment is in place and is properly set up. This approach, based on risk, improves overall well control and assists with compliance with regulations.

Post-Operation Analysis and Continuous Improvement

After having completed a snubbing-enabled P&A campaign, simulation platforms can be utilized for post-operation review. Engineers can evaluate plans against. The actual results assess the behavior of equipment and pinpoint opportunities to improve the efficiency of future projects. These findings contribute to an ongoing loop of learning, which improves efficiency and safety standards for future abandonment projects.

Summary

The integration of snubbing units into plug and abandonment workflows is a significant shift in the way the industry handles well decommissioning, specifically when it comes to in high-risk or live well scenarios. With improved safety, cost-efficiency and environmental stewardship, snubbing units are set to become an essential component of modern abandonment strategies. As regulations get more strict and old wells face increasingly complex challenges, snubbing units provides the control and versatility needed needed to ensure responsible, efficient well retirement.