Innovations in Hydraulic Fracturing for Tight Oil and Shale Gas

Hydraulic fracturing is commonly referred to as fracking, has changed the global energy landscape through the ability to extract tight oil and shale gas resources previously thought to be uneconomic to extract. By improving the permeability and strength of rock formations with low porosity, the technique has uncovered vast hydrocarbon reserves, which have transformed the energy markets, ensuring energy security for a variety of countries.

What is Hydraulic Fracturing

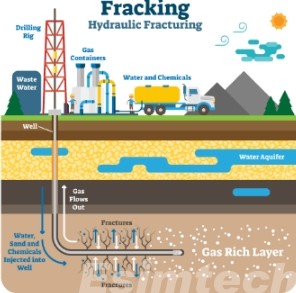

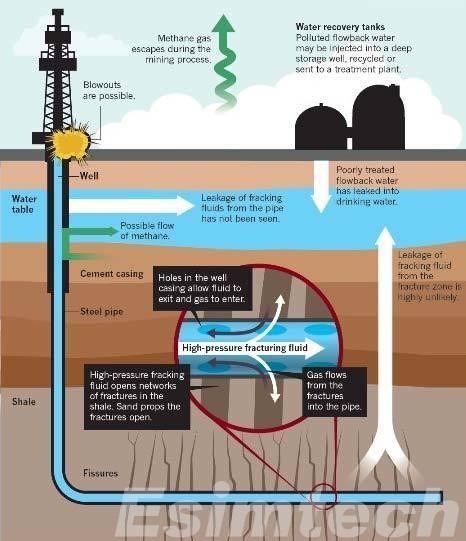

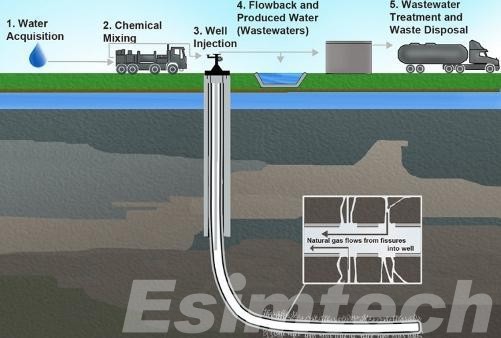

Hydraulic fracturing can be described as a stimulation method used to extract natural gas and oil from reservoirs with low permeability, such as shale and tightly packed sandstone. The procedure involves:

- Drilling a well vertically and later horizontally through the rock reservoir.

- Injecting high-pressure fluid, typically water mixed with additives and sand the well.

- Making cracks in the rock to let gas or oil be able to flow through the wellbore more easily.

- Sand (proppant) is retained within the cracks, allowing them to remain open.

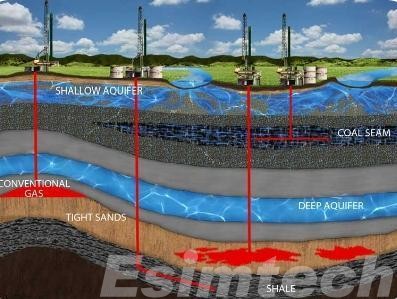

Understanding Tight Oil and Shale Gas

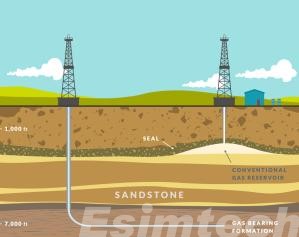

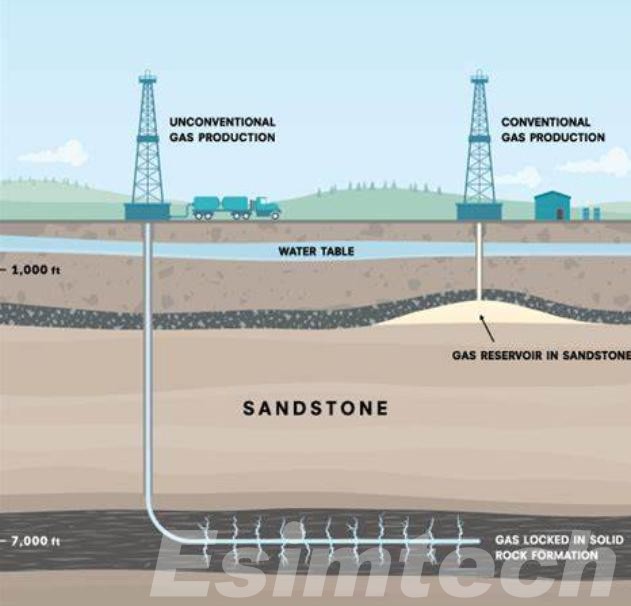

Tight oil and shale gas are two types of hydrocarbons that are found in rock formations with low permeability. Tight oil is the name given to crude oil that is trapped in dense carbonate or sandstone rocks, and shale gas is natural gas that is stored in fine-grained shale rocks. Both of these resources require advanced extraction techniques, such as horizontal drilling and hydraulic fracturing, to release the hydrocarbons trapped and open up vast energy reserves previously not economically viable to extract. These resources have greatly increased the supply of gas and oil in the world,particularly in regions such as North America.

Technological Innovations in Hydraulic Fracturing for Tight Oil and Shale Gas

1. Horizontal Drilling and Multi-Stage Fracturing

The most significant breakthrough in hydraulic fracturing is the widespread adoption of horizontal drilling. This lets wells extend further into the reservoir rock instead of only vertically. This opens up a larger extent of formation, thereby increasing the production possibilities. With multi-stage fracturing, operators can make numerous fracture zones in the horizontal part of the wellbore. By carefully arranging these fracturing steps, this technique can maximize the contact between reservoirs and recoveries of hydrocarbons and transform previously unproductive oil wells to highly profitable ones.

2. Advanced Fracturing Fluids and Proppants

The formulation and choice of proppants and fracturing fluids have changed significantly. Modern fracturing fluids have been designed to decrease corrosion and friction and improve the flow of fluids, and reduce environmental impacts. New developments include the use of organic and non-toxic additives to improve the performance of fluids without harming safety.

Proppants, which are solid materials such as ceramic beads or sand that allow fractures to remain open, have seen advancements including resin coatings, as well as ultra-lightweight designs. These advancements increase the durability and conductivity of fractures, providing a continuous flow of hydrocarbons as well as longer longevity of wells.

3. Real-Time Monitoring and Data Analytics

Digital technology has brought an era of greater precision and controlled hydraulic fracture. Real-time monitoring with downhole sensors detects temperature, pressure, and the propagation of fractures when operations are progressing. The data, in conjunction with sophisticated analytics and machine learning algorithms, permits operators to optimize dynamically fracture parameters, reduce the complexity of fractures, and decrease risk to operations. This results in improved efficiency, lower costs, as well as improved performance.

4. Environmental Innovations and Water Management

Environmental concerns have become a major concern in the field of hydraulic fracturing. The latest innovations in water recycling and treatment can reduce the use of freshwater as well as the volume of waste that has to be disposed. Closed-loop systems and improved techniques for handling help to contain as well as reuse the fluids from flowback, making it easier to reduce the footprint of our environment.

Furthermore, research into chemical-free (green fracturing) fluids seeks to remove harmful additives, decreasing the risk of groundwater contamination and exposure to the community and its workers.

5. Microseismic and Geophysical Technologies

To ensure safety during operation and environmental protection, microseismic monitors have become a common practice during hydraulic fractures. This method detects small seismic waves due to the growth of the fracture and allows for the precise visualization of the fracture network. Knowing the behavior of fractures in real-time helps operators keep out unwanted propagation from the zone of interest and minimizes the possibility of seismicity caused by induced.

In conjunction with advancements in geophysical image processing, these techniques enhance the control and predictability of fracturing. This improves both safety and management of reservoirs.

Environmental and Operational Considerations for Hydraulic Fracturing in Tight Oil and Shale Gas

| Category | Considerations | Mitigation Strategies |

| Water Usage | Huge volumes of water are required for fracturing fluids | Recycle water, find alternative water sources, as well as efficient use |

| Water Contamination | Potential risk of groundwater contamination due to flowback fluids or chemicals | Casing for wells that are properly installed, chemical disclosure, and containment systems |

| Wastewater Management | Treatment and disposal of produced and flowback water | Recycling, treatment disposal that are safe, closed-loop systems |

| Air Emissions | Releases of methane as well as emissions from Volatile organic compounds (VOCs) | Leak detection, monitoring of well integrity, and vapor recovery units |

| Induced Seismicity | Minor earthquakes are triggered by the injection of fluid | Microseismic monitoring, as well as controlled injection rates, and the zoning |

| Chemical Use | The use of potentially harmful additives in the fracturing fluids | Utilization of biodegradable, non-toxic components and full disclosure of chemical information |

| Noise and Light Pollution | The impact on communities around the area when drilling or fracturing activities | Make use of noise barriers, schedule operations, and reduce the use of light equipment. |

| Land Use and Habitat | Surface disturbances that affect ecosystems and wildlife | Site plan, habitat rehabilitation, and the reduction of footprint |

| Operational Safety | High-pressure equipment and handling of dangerous substances | Complete training as well as safety protocols and emergency plans for response |

Economic and Geopolitical Impact of Hydraulic Fracturing for Tight Oil and Shale Gas

| Impact Area | Details | Consequences/Benefits |

| Energy Independence | Lower reliance on imported crude gas and oil | National energy security is improved and geopolitical leverage |

| Increased Energy Supply | A significant increase in the domestic production of gas and oil | Global energy markets are stabilized and have decreased price volatility |

| Economic Growth | Employment creation in the drilling and services industries, manufacturing, infrastructure, and drilling | An increase in national and regional economies |

| Investment Opportunities | Attraction of capital for exploration, production, and related industries | Technology and innovation |

| Global Energy Market Shift | US, along with other producer countries, has become into important exporter | Trade balances fluctuate and have an impact on gthe lobal supply |

| Energy Price Impact | Supply growth is a factor in lower prices for gas and oil | Cost savings and consumer savings for businesses |

| Environmental Regulations | New regulations and policies are shaping the operational practices | Balance between economic growth and protecting the environment |

| Geopolitical Relations | Dependencies and alliances that have changed because of changes in control of energy resources | Potentially less influence on traditional oil exporters |

| Energy Transition Role | Natural gas is a fuel for bridges that supports low-carbon energy systems | Helps to facilitate a gradual shift towards renewable energy |

How Simulation Technology is Used for Hydraulic Fracturing in Tight Oil and Shale Gas

Simulation technology is essential in the process of hydraulic fracturing, aiding operators and engineersto optimize the design of wells, minimize risk and increase the efficiency of extracting tight oil and shale gas. Because of the complicated subsurface formations and the intricacies of fracture propagation, oil and gas simulation tools offer a virtual environment that allows for the modeling and predicting of future outcomes before actual field operations begin.

Fracture Design and Optimization

Fracturing simulators allow engineers to analyze the propagation and initiation of fractures in rich shale gas and oil formations. By creating precise reservoir and geomechanical models, engineers can anticipate how fractures are likely to form under different circumstances. This permits precise planning of the fracture phases, fluid volumes, and proppant positioning to optimize the contact between reservoirs and enhance the flow of hydrocarbons and increase the effectiveness of the fracturing procedure.

Reservoir Behavior Prediction and Production Forecasting

Simulations incorporate geological data along with rock properties and fluid dynamics to forecast the way that reservoirs will react to the process of hydraulic fracturing as time passes. This assists operators in estimating production rates and determining the best drilling sites, which aids in the economic analysis and strategic decision-making. A precise forecasting process reduces uncertainties and increases the viability of projects.

Risk Management and Environmental Protection

Simulation is a key element in identifying the potential dangers associated with hydraulic fracture. It is able to model unintentional fracture expansion, fluid migration, and induced seismicity, making it possible for operators to develop more secure fracturing strategies that minimize environmental impact. With predictive analysis, companies are able to comply with regulations and follow the best practices to safeguard the ecosystems that surround them.

Real-Time Monitoring and Digital Twins

Innovative simulation instruments, like digital twin technologies, give real-time simulations of hydraulic fracturing activities. By constantly integrating data from sensors throughout fracturing processes, operators can adjust parameters in real-time to improve efficiency, decrease downtime, and increase security. This method provides better operating control and is more responsive to the changing conditions of the subsurface.

Future Outlook in Hydraulic Fracturing for Tight Oil and Shale Gas

Hydraulic fracturing is likely to remain a crucial technology to access gas and oil in shale formations that are tight reserves for a long time to come. The continuous advances in fracturing and drilling techniques will enhance the effectiveness and efficiency of extracting hydrocarbons from these difficult formations.

Continued Technological Innovation

Hydraulic fracturing’s future is dependent on the ongoing technological advancements. Modern advances in digitalization like artificial intelligence, machine learning, machine learning and real-time analytics of data, have improved the accuracy of well design, well placement, and optimization of production. These tools allow operators to increase hydrocarbon recovery while decreasing costs and impact on the environment. Automation and remote monitoring are likely to increase the safety of workers and improve efficiency at drilling sites.

Emphasis on Environmental Sustainability

Environmental issues continue to influence the direction of hydraulic fracture. Industry is investing massively in the development of technologies that can reduce the use of water, enhance the treatment of wastewater, and replace harmful chemicals using green alternatives. The recycling of fluids used in fracturing, as well as closed-loop systems to manage water are now becoming the norm. Additionally, advancements in microseismic monitoring as well as induced seismicity management reduce the environmental risk, making sure that the safety of the fracturing process and accountability.

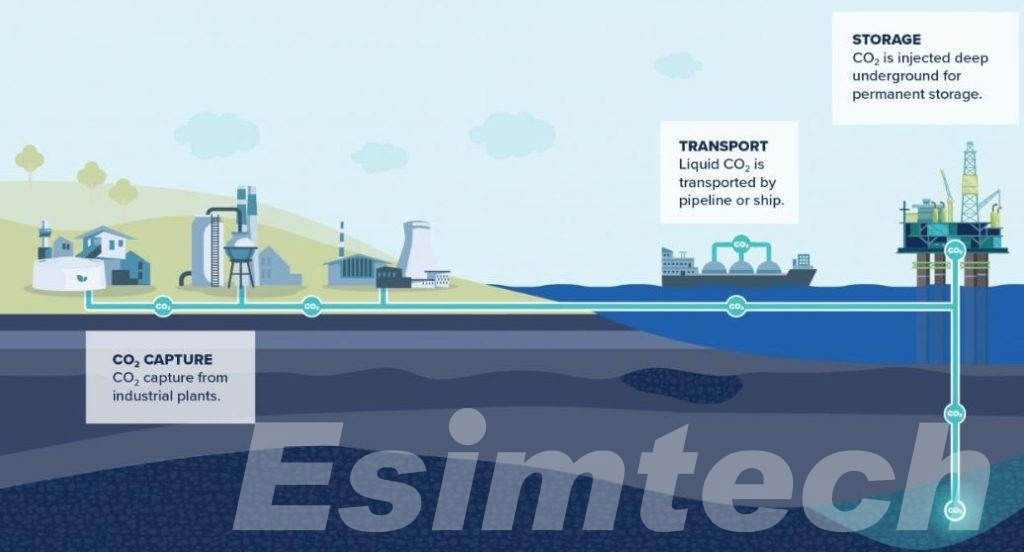

Role in the Global Energy Transition

As the world moves towards more sustainable energy sources, the hydraulic fracturing process is positioned as a key technology for bridges. Natural gas generated by the process of fracturing can be a low-carbon alternative to oil and coal, offering flexibility and dependability to supplement renewable energy sources such as solar and wind. Innovative solutions that combine hydraulic fracturing and carbon storage and capture (CCS) techniques are on the rise, with the goal of helping lower greenhouse gases that are associated with extracting fossil fuels.

Growth into New Regions

Although North America currently leads hydraulic drilling, the development of new shale basins across the globe is attracting attention. Countries across Latin America, Asia, and Europe are exploring and developing their untapped resources and adapting their fracturing techniques to local conditions of geology and regulations. Global expansion offers opportunities for diversification of energy and economic growth, but it also requires cautious management of social and environmental impacts.

Regulatory and Social Challenges

Growth in the future will also be contingent on the changing regulatory landscape and the public’s perception. Governments are increasingly adopting stricter environmental standards and requiring transparency, accountability and best practices from operators. Engaging stakeholders and communities through effective communication and demonstrating a commitment to sustainability is crucial for maintaining the social licence to operate.

Final Thoughts

Hydraulic fracturing makes it possible to harness the vast potential of tight oil and shale gas, turning previously uneconomical formations into abundant energy sources. While it presents regulatory and environmental challenges but continued advancement and ethical practices are expected to keep fracking at the center of the global energy policy, thereby providing a vital bridge in the transition toward a more diversified and sustainable energy future.