Top 5 Technologies Powering Ultra Deepwater Drilling

Ultra deepwater drilling is today the most challenging and exciting area of the oil and gas industry. At often more than 1,500 meters (5,000 feet) deep, these projects push the boundaries of engineering, safety, and technology. From Brazil’s pre-salt reservoirs to the Gulf of Mexico, ultra-deepwater drilling opens up reserves that were previously out of reach. But under extreme pressure, high temperature, and remote offshore conditions come complex working challenges. To address these challenges, the industry relies on advanced technology to enhance safety, efficiency, and sustainability.

What Exactly is Ultra Deepwater Drilling?

As compared to deepwater drilling, ultra deep water drilling takes place in much more unfavourable conditions, where high pressure, low temperature, and long distances offshore present particular engineering difficulties. Well integrity preservation, control of complex pressure conditions, and preserving safe subsea operations are key to operators. These ventures require specialized rigs, advanced drilling equipment, and sophisticated monitoring systems to control risks such as blowouts, formation instability, and equipment failure.

With increasing global demand for energy, ultra deepwater drilling provides the ability to access reserves which might otherwise be out of reach, including pre-salt reservoirs and distant offshore basins. With the infusion of sophisticated technologies and experienced operating strategies, ultra deepwater drilling plays an important role in sustaining the world’s energy supply and pushing the frontiers of modern engineering.

Top 5 Technologies in Deepwater Drilling

Ultra deepwater drilling is among the most technologically challenging areas of offshore oil and gas production. Operating in water depths often exceeding 1,500 meters, such operations face record pressures, cold temperatures, and remote-offshore conditions. To counter such challenges, the industry relies on advanced technologies assuring enhanced operational safety, efficiency, and dependability. The top five technologies driving modern ultra deepwater drilling activities are listed below, each playing a crucial role in accessing previously unexploited reserves.

High-Pressure High-Temperature (HPHT) Drilling

High-Pressure High-Temperature (HPHT) drilling is the essence of ultra deepwater drilling operations in which wells are exposed to pressures exceeding 15,000 psi and temperatures exceeding 350°F. The harsh conditions necessitate specific drill bits, casings, and drilling fluids that do not rupture under structural stress causing the well collapse. HPHT technology also encompasses real-time downhole monitoring systems that track temperature and pressure so that operators can make rapid adjustments to drilling parameters. For example, HPHT techniques have been important in the Gulf of Mexico deepwater reservoirs, allowing for safe production from previously-too-risky reservoirs. In preventing hazards of operation, HPHT drilling ensures safety along with productivity in ultra deep water drilling operations.

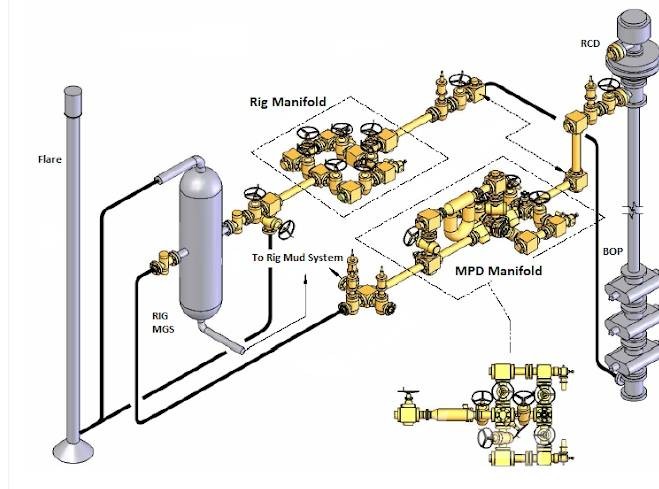

Managed Pressure Drilling (MPD)

Managed Pressure Drilling (MPD) is an active method that provides precise wellbore pressure control throughout the drilling process. In ultra deepwater drilling, small pressure changes can trigger blowouts, ruin formations, or slow down drilling. MPD systems make constant real-time drilling fluid density adjustments, maintaining perfect pressure balance between the wellbore and surrounding formations. This technology reduces idle time, prevents costly accidents, and enhances the drilling efficiency. MPD was applied successfully to complex offshore operations, such as ultra-deep pre-salt reservoirs in Brazilian fields, where it has made safer penetration of high-pressure zones possible with more minimal environmental risk.

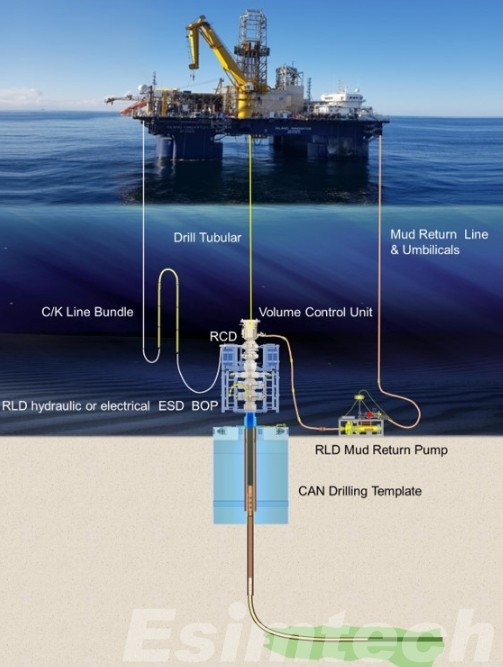

Dual-Gradient Drilling (DGD)

Dual-Gradient Drilling (DGD) is a new technique developed to manage wellbore pressures for ultra deepwater wells. Unlike classic single-gradient systems, DGD utilizes two different fluid density gradients to counteract formation pressure and reduce stress around the wellbore. This allows for deeper drilling with less chance of kicks or blowouts. DGD has been especially valuable in ultra deep water drilling where conventional methods fail, enabling operators to reach reservoirs previously thought impossible to reach. The technique also allows for increased rates of drilling and reduced costs of drilling in total, and is hence a main motivator for economically rational ultra deepwater operations.

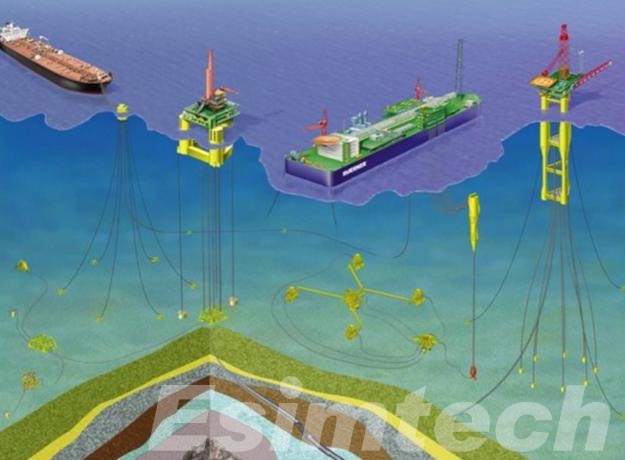

Subsea Production Systems

Subsea production systems are the foundation of today’s ultra deepwater drilling operations. Subsea manifolds, risers, flowlines, and umbilicals transport oil and gas from the seafloor to surface facilities or floating platforms. Subsea robotics and remotely operated vehicles (ROVs) facilitate installation, inspection, and maintenance under harsh deepwater conditions, offering operating reliability. Advances in subsea separation, boosting, and compression technology make it possible for hydrocarbons to be efficiently processed and transported even from ultra-deep reservoirs. Subsea systems combined with FPSO in West Africa and the Gulf of Mexico, for example, have demonstrated excellent efficiencies in production, which illustrates the strategic importance of subsea technology for ultra deep water drilling.

Digital Twin and AI Monitoring

Ultra deepwater drilling is being revolutionized by digital twin technology and AI monitoring, with predictive operations and real-time optimization. Digital twin can be described as a virtual copy of the drilling rig, subsea infrastructure, and wellbore, allowing engineers to model operational conditions and identify potential risks in advance. Data from thousands of sensors is being monitored by AI algorithms, which predict equipment breakdown, optimize drilling parameters, and make the process safer. This convergence, as well as reducing downtime, improves decision-making for advanced ultra deep water drilling operations. Digital twin platforms are currently being used by leading operators to monitor several rigs simultaneously, highlighting the importance of digital transformation to the next ultra deepwater generation.

The Future of Ultra Deepwater Drilling

Technological advancement, sustainability, and efficiency of operations are shaping the future of ultra deepwater drilling. Growing energy demand for the sector and tougher environmental regulations are compelling operators to depend more on cutting-edge solutions that improve safety, reduce cost, and reduce environmental impact. Increasingly, ultra deep water drilling will rely on implementing digital technologies, automation, and low-carbon strategy to ensure projects remain economically competitive while still being environmentally sustainable.

Some of the major trends and developments shaping the future are:

- Electrification of Offshore Platforms: Replacement of diesel generators with electricity to reduce carbon footprint and improve energy efficiency.

- Hybrid Energy Systems: Harmonization of oil and gas production with renewable energy such as offshore wind power to facilitate sustainable operations.

- Advanced Materials: Utilization of corrosion-resistant alloys and light composite materials to extend subsea equipment life and improve reliability.

- Digital Twin and AI Analytics: Enabling real-time monitoring, predictive maintenance, and optimization of drilling operations.

- Autonomous and Remote Operations: Minimizing human exposure to dangerous circumstances and enhancing operational effectiveness.

- Sustainable Drilling Practices: Implementing low-carbon technologies and carbon management practices to enable net-zero targets.

These developments describe how ultra deepwater drilling is transforming beyond traditional extraction processes. Adopting digital innovation, automation, and green technologies, the industry can economically and safely tap into reserves that hitherto were inaccessible while minimizing environmental impact. The integration of these technologies and methods will define the next phase of ultra deep water drilling to make offshore energy a reliable and sustainable part of global energy supply.

Summary

Ultra deepwater drilling is one of these heights of offshore engineering, representing the combination of state-of-the-art technology, expertise, and innovation. The key technologies—High-Pressure High-Temperature (HPHT) drilling, Managed Pressure Drilling (MPD), Dual-Gradient Drilling (DGD), subsea production systems, and digital twin with AI monitoring—are what enable operators to drill safely into deepwater hydrocarbon reservoirs.

To the future, tomorrow’s ultra-deepwater drilling will be focused on sustainability, automation, and digital optimization. With the integration of renewable energy, low-carbon solutions, and predictive analytics, operators can enhance safety, efficiency, and environmental stewardship. These innovations ensure that ultra deepwater drilling continues to be a key enabler of challenging offshore resources while meeting global energy demands in a sustainable way.