What Is Well Integrity and Why It Matters in Modern Oilfield Operations

Whether a deeply rooted offshore field or an aged onshore reservoir, maintaining the structural integrity of a well is essential to prevent leaks, conserve the environment, and maintain steady production.

With drilling technology improvement and global energy ambitions shifting toward sustainability, the concept of oil well integrity has grown in importance. No longer is it just a technical requirement—it's now an essential measure of operational superiority and corporate responsibility.

Understanding Well Integrity

What Is Well Integrity?

Put simply, well integrity is the assurance that a well can safely contain and control the fluids and gases within it throughout its entire life. From the start of drilling to abandonment, a well should be a sealed and stable system-separating hydrocarbons from the world while maintaining safe conditions for production.

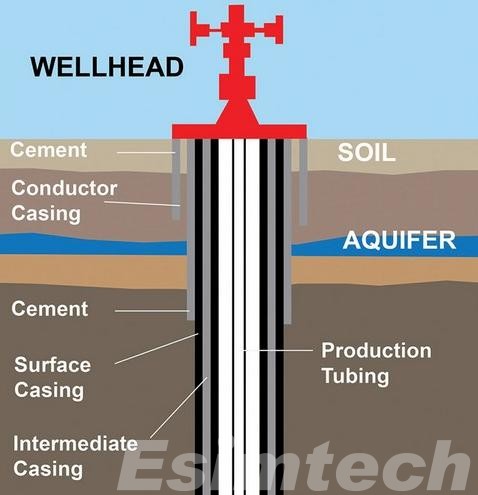

The concept is founded on one simple principle: containment. Every well needs to have multiple physical and functional barriers that do not permit any undesirable fluid movement to the surface or between subsurface zones. These barriers—primary (e.g., tubing and packers) and secondary (e.g., casing and cement)—work together to maintain wellbore integrity and keep the well in control at all times.

An integrity well protects people, the environment, and assets for the company. Conversely, any loss of integrity can lead to safety accidents, production loss, or environmental pollution—risks that modern operators cannot just ignore.

Key Components of Well Integrity

Maintaining oil well integrity involves the combined performance of several interdependent components, all designed to ensure pressure retention and fluid isolation:

- Casing and Cement: The casing provides structural strength to the well, and cement forms a hard seal between the casing and rock. They together seal crossflow between formations in the geology and protect groundwater resources.

- Tubing and Wellhead Systems: The tubing is the controlled path for produced fluids to pass safely to the surface, and wellhead seals and controls pressure at the surface facilities-well interface.

- Annular Pressure Control: Pressure control and monitoring in annular spaces between casings is vital. Uncontrolled annular pressure buildup (APB) could pose risk to structural barriers of the well.

- Monitoring and Verification Tools: Continual monitoring—using downhole sensors, temperature and pressure gauges, and real-time computer systems—allows operators to detect stress, corrosion, or leakage precursors before they result in failures.

Combined, these elements create a complete well integrity management system that ensures every barrier is tested, qualified, and recorded throughout the life of the well. This combined solution not only adds to safety and compliance but also extends the productive life of the asset—making well integrity one of the most important pillars of support in today's oilfield operations.

Why Well Integrity Matters in Modern Oilfield Operations

Well integrity in the modern energy world is far more than a technical requirement — it is an integral responsibility to enable safe, effective, and sustainable oil and gas production. Every producing well is simultaneously an opportunity and a risk: an opportunity to produce energy assets, and a risk if its confinements fail. Wellbore integrity throughout the life cycle of a well protects people, the earth, and company reputation.

1. Safeguarding Individuals and the Environment

Safety is the number one reason why oil well integrity must be maintained. Failure in containment can lead to disastrous blowouts, leakage of gases, or contamination of groundwater. These accidents not only threaten human lives, but they can also usher in irreversible harm to the environment and tremendous economic loss.

By operating all well barriers properly, operators prevent uncontrolled release of hydrocarbons and minimize the risk of methane emissions — a growing environmental concern. Correct well integrity management directly relates to the industry's overall objective of sustainable and responsible operations.

2. Enhancing Operational Performance and Asset Worth

Aspects of good well integrity have a direct influence on operational economics and reliability. A fluid-contained and pressure-controlled well runs better, shuts down less often unexpectedly, and requires intervention less frequently.

Conversely, integrity issues such as extended casing pressure or corrosion can lead to expensive workovers, reduced production, or early abandonment. Operators can extend the life of their assets, conserve on maintenance costs, and achieve more predictable production outcomes by investing in proactive well integrity monitoring.

3. Meeting Regulatory and ESG Expectations

All regional and global regulatory bodies, including the Bureau of Safety and Environmental Enforcement (BSEE) and followers of ISO 16530-1, API RP 90, or NORSOK D-010, have been clear regarding well integrity management systems. Protecting the environment and operating legally demands more than good intention; it requires compliance.

The integrity of wells is considered ESG (Environmental, Social, and Governance) performance by almost all investors and stakeholders, regardless of your industry or sector. The environmental impact of your operations is documented, the risk is transparent, and the technical discipline exercised is respected by all partners, regulatory bodies, and the public.

Well integrity connects safety, sustainability, and profitability through responsible hydrocarbon production and operational reliability to environmental protection. The industry allows little margin for error and intense public scrutiny. Upholding well integrity is more than good practice; it is compliance.

How Operators Maintain Well Integrity

Well integrity management is a continuing process that extends through the life of a well—from design and drilling to production and final abandonment. Integrity is not a single inspection, but a long-term discipline supported by technology, data, and proactive management for successful operators.

Modern practices of wellbore integrity combine real-time monitoring, predictive analytics, and formal integrity management systems to identify and address issues prior to their becoming severe.

1. Continuous Monitoring and Diagnostics

Well integrity monitoring begins with extensive, real-time data gathering. Downhole sensors monitor pressure, temperature, and flow dynamics, while surface gear tracks annular pressures and wellhead function. Continuous streams of data give engineers the capability to detect anomalies that may point to corrosion, leakage, or barrier failure.

Emerging technologies transform operators' understanding of integrity assurance. Distributed acoustic sensing, acoustic leak detection, and distributed temperature systems (DTS) enable early detection of wellbore changes. Digital twins—virtual copies simulating the real well's performance—enable engineers to test operating conditions, predict potential failures, and initiate data-driven maintenance.

Through the integration of these tools with AI and machine learning, operators can shift from reactive maintenance to predictive integrity management, reducing downtime and risk significantly.

2. Preventive Maintenance and Targeted Intervention

Even with advanced monitoring, every well will need routine testing and intervention to guarantee barrier performance. Operators conduct pressure integrity tests, inflow tests, and annular bleed-off activities to confirm containment barriers are not breached.

When diagnosed, focused interventions such as remedial cementing, casing repair, or packer replacement can restore the integrity of oil wells. All these interventions are possible with precise diagnostic data, preventing unnecessary interventions and reducing the operation cost.

Preventive maintenance programs also manage long-term degradation causes such as CO₂ corrosion, exposure to H₂S, and microbial-induced damage—significant threats for onshore and offshore operations.

3. Integrated Well Integrity Management Systems

Organizational level is ensured by a well-structured Well Integrity Management System (WIMS) that provides the platform for transparent and consistent management. These systems integrate engineering norms, field procedures, monitoring data, and regulatory specifications into a single digital platform.

With risk-based inspection (RBI) strategies, operators are able to prioritize wells by criticality and allocate resources effectively. Cloud-based dashboards and automated alerts provide decision-makers with real-time insight into each well's barrier status and compliance history.

This end-to-end, data-driven strategy not only increases operational control but also ensures reporting reliability—allowing companies to keep up with evolving safety and ESG expectations with confidence.

4. The Shift Toward Predictive Integrity

Now that the oil and gas sector has embraced digital transformation, prediction is the way of the future for well integrity management as a replacement for reacting. With the integration of big data analytics, machine learning algorithms, and smart sensors, operators are able to predict barrier degradation and prevent failure before it occurs.

Predictive integrity is a paradigm shift: from ad hoc inspection to continuous assurance, from spreadsheet to intelligent systems, from fix for cause to stewardship by design. This shift not only increases safety and performance but also furthers the greater goal of sustainable and responsible energy generation.

In essence, maintaining well integrity in today's world is about combining engineering discipline with digital savvy. The best operators are those who grasp integrity management not only as an Iron Checklist regulatory compliance, but as a strategic advantage—one that protects people, prevents harm to the environment, and maximizes asset value over time.

Wrapping Up

Well integrity in the modern energy business is greater than an engineering necessity—it's the passport to secure, efficient, and responsible oilfield production. By embracing strong wellbore integrity, operators safeguard people, the environment, and asset value while meeting tight regulatory and ESG requirements. With digitalization and predictive analytics more entrenched than ever, the future of oil well integrity lies in proactive management and data-driven decision-making. Finally, holding integrity at every step of the life cycle of a well is not just good practice—it's essential to responsible and resilient energy development.