Combining Coiled Tubing and Snubbing for Enhancing Well Intervention Efficiency

In the constantly evolving field of oil and gas well intervention, the combined use of coiled tubing and snubbing has emerged as an effective and versatile method to tackle the most difficult downhole challenges. Through using the strengths of both technologies, operators are able to perform a wider range of operations under pressure, reducing non-productive time and enhancing safety and efficiency.

What is Coiled Tubing and Snubbing?

Coiled tubing is an unbroken length of small-diameter pipe that is wound on a reel before being put into wells when under pressure. It is used extensively for cleaning outs and acidizing, fracturing and logging, without the requirement of killing the well.

Snubbing is the process of inserting and removing a joined pipe under pressure by using hydraulic Jacks. It is especially helpful in dealing with high-pressure wells, which cannot be killed without risking damage to the formation or loss of control of the well.

Although each technique has distinct capabilities, their combination creates new possibilities for improved well-intervention.

Why Combine Coiled Tubing and Snubbing?

The combination of coiled tubing and snubbing is an effective solution to complicated intervention problems, especially in live wells and high-pressure conditions.

The Need for Advanced Well Intervention Solutions

Modern wells are deeper, more pressurized, and more complicated than ever before. This means that conventional intervention techniques often fail when it comes to live wells, or operations that require flexibility as well as force. Coiled tubing is a great choice for ongoing interventions such as cleaning out, fluid placement, and logging, in particular horizontal or deviated wells. Snubbing is also a great option in high-pressure situations where jointed pipe is required to be removed or inserted safely without harming the well.

When they are paired, these two technologies will allow for a wider range of tasks downhole, with improved control, decreased downtime, and less risk.

Complementary Capabilities

The main reason to combine both snubbing and coiled tubing is in their strengths as complementary operations. Coiled tubing is able to run real-time pumping circulation as well as downhole tool manipulation, with minimal area footprint and rapid deployment. Snubbing, on the other hand, offers the advantages of mechanical strength and structural strength required to manage bigger bottomhole assemblies as well as perform the heavy-duty work under pressure.

When combined, the coiled tubing can handle simple and continuous processes like chemical treatment or jetting, while the snubbing system handles the transitions that require changes to toolstrings or mechanical setting of plugs or re-use of equipment that is rigid or heavy without disrupting the well’s pressure integrity.

Maintaining Well Control Without Killing the Well

One of the major benefits of this combination method is the possibility to interfere with live wells without destroying the wells. The act of killing a well, stopping production to lower pressure, can harm the reservoir, raise operating costs, and lengthen the duration of. Combining coiled tubing with snubbing, workers can ensure that pressure is controlled throughout the process, reducing the risks involved with restarting and killing a well.

This ability is especially valuable when the reservoirs are not balanced or in gas sour environments in which the dangers of formation damage are more pronounced.

Enhancing Operational Efficiency

Utilizing snubbing and coiled tubing in conjunction can boost efficiency by reducing the need for equipment mobilization and demobilization in the middle of an action. Instead of having to switch out teams and setups, it is possible to be seamlessly moved between coiled tubing work and snubbing. This can not only reduce the timeframe but also reduce the chance of making mistakes during equipment transitions.

Additionally, wellsite logistics profit from fewer interruptions and efficient workflows that allow teams to react quickly to unexpected problems downhole.

Applications of Combined Coiled Tubing and Snubbing

| Application | Description | Role of Coiled Tubing | Role of Snubbing |

| Live Well Cleanouts | Cleaning out scale, sand, or other debris from live wells | Continuous circulation and jetting | Maintains pressure control during operation |

| Fishing Operations | Retrieving equipment or tools that are stuck | Spots chemicals and assists with circulation/agitation | Heavy fishing equipment is deployed under pressure |

| Underbalanced Perforating | Perforating the well without harming it | Perforates guns and maintains the flow | Controls tension and handles tool transitions |

| Plug and Packer Installation | Isolation tools are used to set up in wells with high pressure | Helps to ensure precise placement and fluid delivery | Mechanically sets bigger plugs or packers |

| Well Integrity Repairs | Repairing leaks in casings, patching, repairing or setting, or the restoration of zones of isolation | Provides sealants or diagnostic tools | Installs structural elements and ensures that they are in control |

| Underbalanced Drilling/Milling | Milling or drilling in pressurized wells | Provides power to downhole motors and the flow of fluid | Manages large tool strings and regulates the movement of pipes |

| Sour Gas/HPHT Interventions | Operations in hazardous or high-pressure/high-temperature environments | Limits risk exposure and supports the need for continuous operations | Keeps well-controlled and safe in extreme conditions |

| Horizontal/ERD Well Interventions | Accessing deviated or extended-reach wellbores | Explores complicated geometries and is flexible | Assists with handling tools and the management of weight |

Key Considerations for Successful Combining Coiled Tubing and Snubbing

1. Well Pressure and Flow Dynamics

Before the deployment of both coiled tubing and snubbing, it is essential to know about the well pressure profile as well as the behavior of the fluid. Overpressure or sour gas wells, or unbalanced conditions, are generally best suited for combined operations. Cautious pressure analysis decides if both systems are ready to use and safe.

2. Ensuring Surface Equipment Compatibility

The surface coiled tubing and snubbing unit joining has to be smooth. The equipment like BOP stacks, pressure control equipment, injector heads, and lubricators, has to be compatible in terms of size, pressure ratings, and operating sequence. Any misalignment of the equipment can lead to rig-up delays or safety issues.

3. Planning Operational Sequences

A straightforward and explicit step-by-step intervention is required. Operators must explicitly show the time and mode by which every system will be utilized to implement tool change or pressure shift, and emergency response. The plan must address each detail of the work from mobilization to last pressure test in such a way that there is coordination and non-concurrent actions between the two systems.

4. Coordinating Personnel and Training

Hybrid operations require staff who understand both technologies. Cross-trained or coordinated coiled tubing personnel as well as team members, need to be hired for safety, communications, and effective operation. Pre-job briefings along with safety meetings,s are required to make sure both teams are on the same page in the whole operation.

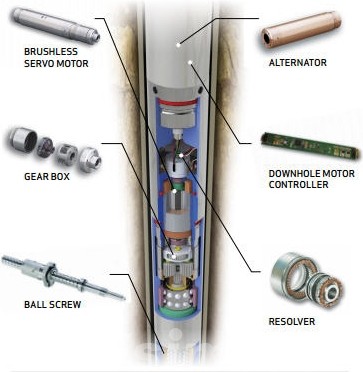

5. Selecting Suitable Downhole Tools

Downhole tools to be selected need to be compatible with the snubbing and coiled tubing systems. Coiled tubing is typically utilized for lighter, more flexible tools, while snubbing is used for bigger, more rigid structures. The operation could be made necessary by modular tooling or stepwise deployment techniques, taking into consideration the system’s capabilities and constraints in issue.

6. The Importance of Safety Throughout Pressure Control

Limiting casing pressure is critical during “live well” combined operations. Operators should automate real-time pressure monitoring and emergency shut-in, alongside safety barriers. Protocols must also be established to ensure employee and equipment safety during operations.

7. Managing Mobility and Rig Up Time

The combined footprint of snubbing and coiled tubing operations is considerable. The site design should allow for both systems without impacting other infrastructure or limiting access. Smart rig-up planning should be directed so that all system components function within a defined installation site.

8. The Role of Communication in Continuous Monitoring

Cross-disciplinary collaboration is critical. Informs have to share real-time consolidated data from different subsystems with operations on the surface. Coiled tubing and snubbing crews have to be in constant communication about downhole conditions and the system’s performance. Mistakes and delays during critical phases of operations can be eliminated through centralized monitoring and communication systems.

9. Following Industry Regulations

It is the responsibility of the operators to make certain that standard procedures for the regional requirements of pressure control and live well interventions, as well as the protection of employee safety, are met. Compliance may prevent legal action, might also aid in operational safety, and can protect the environment.

How Simulation Technology is Used for Combining Coiled Tubing and Snubbing

Simulation technology adopts sophisticated digital modeling tools and virtual training platforms. Operators are able to better understand the dynamic interactions between the coiled tubing and snubbing. They can also forecast performance under real-world situations, while ensuring the safety of operators and ensuring operational efficiency.

Pre-Job Engineering and Operational Planning

Well intervention simulation is most importantly used to model the wellbore’s environment and interventions. By inputting real well data, such as pressure gradients, temperature profiles, tubing dimensions, and tool configurations, engineers can simulate how both coiled tubing and snubbing systems will behave when integrated. These simulations aid in determining the most effective interventions as well as predict the behavior of toolstrings and test the pressure control scenario.

For instance, coiled tubing simulators and snubbing simulators are able to model the mechanical interactions between coiled tubing and the heavy bottomhole assemblies which are introduced by snubbing. This can help determine whether the planned actions will surpass the tension or axial limits of the system. Engineers can also study the flow of fluid, circulation efficiency and pressure containment techniques during different phases of operation, ensuring more efficient and safe job execution.

Real-Time Scenario Testing and Contingency Planning

Simulation platforms enable operators to simulate “what-if” scenarios before entering the field. For combining coiled tubing and snubbing operations, this could include simulation of unplanned events like sudden pressure spikes and stuck tools, injector failures, or BOP malfunctions. These scenarios assist teams in developing plans for contingency and verifying emergency response protocols.

Advanced simulators also allow the modeling of transient multiphase flows, which allows engineers to observe how the formation fluids, injected chemicals, and gas slugs interrelate throughout the process. This is particularly important since the well can’t be removed, and any imbalance in pressure can cause blowouts and tool damage.

Training and Competency Development

Combining snubbing and coiled tubing requires a highly coordinated team performance. Simulation-based training offers a secure and cost-effective setting for employees to experience hands-on with both equipment. By using VR and 3D-based snubbing training simulators, employees and supervisors are able to practice all aspects of the workflow, from rig-up through execution, without the dangers associated with field trials.

Instructors can help trainees with the process of setting up equipment and pressure testing, and system adjustments, helping them to understand how the snubbing units and the injector coil operate in real-time pressure conditions. Simulations can be stopped repeatedly, altered, or enhanced to enhance understanding and increase muscle memory in high-risk settings.

Optimizing Tool Selection and Operational Sequence

Simulators permit testing of various configurations of toolstrings and deployments. Through simulation of the operation teams can decide if certain tools are better carried through coiled tubing or snubbing or the hybrid method is required. For instance the case where a long-length plug has to be inserted deep within your well, the coiled tubing simulator will demonstrate whether coiled tube has enough force to bring it there or if it is better to snubbing in order to complete the job.

In addition, simulation aids in optimizing the hand-off point–when to change between snubbing and coiled tubing and vice versa, based on force requirements, pressure and tool compatibility.

Enhancing Real-Time Decision-Making

Some sophisticated digital twin systems connect simulation models with live well data that is generated during the course of operations. These systems provide live information on trends in pressure and tool performance along with fluid dynamics which allows engineers to alter parameters as they go. When you have a combination set-up of coiled tubing and snubbing, this level of real-time feedback is essential for ensuring control throughout shifts or unexpected downhole behaviors.

Summary

The combination of coiled tubing and snubbing can be seen as a powerful improvement in well intervention strategies. By combining the continuous mobility of coiled tubing with the heavy-lift capabilities and pressure management of snubbing, operators can gain new capabilities and efficiency across a wide range of challenging environments. Simulation technology is an integral component of the entire life cycle of combined coiled tubing and snubbing. From precise pre-job modeling up to live training and real-time decision-making support, simulation improves security, enhancing coordination and helping maximize operational efficiency.