ESIM-FCT1L Full Size Coiled Tubing Simulator

- Adopt non-sequence simulation software structure, and there is no restriction on operation sequence.

- Practice multiple items such as running and pulling coiled tubing, open and close BOP, adjust injector pressure, etc. in one snapshot.

- Problems can be inserted at any time during exercise.

- Parameters can be set freely.

- Automatic scoring function.

1. System Introduction

The coiled tubing simulation training system is developed by Chengdu Esimtech Petroleum Equipment Simulation Technology Exploitation Co., Ltd. It is the simulation training system with advanced technology, and can satisfy training demand in the industry.

The coiled tubing simulation training system is the product combining petroleum engineering technology with computer technology. Now the system can provide the common downhole operation and accident treating training items such as drilling bridge plug, sand washing, gas-lift discharge, etc. It is mainly used for training new personnel, coiled tubing operator, coiled tubing team leader, etc. Through the training with the system, trainees can master the basic operation of coiled tubing, common technology process of coiled tubing and common accidents and troubles treating in the process of coiled tubing.

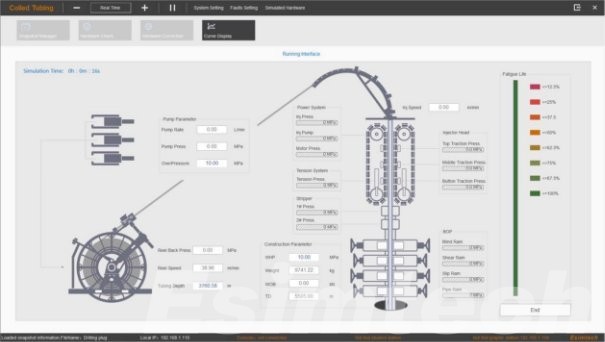

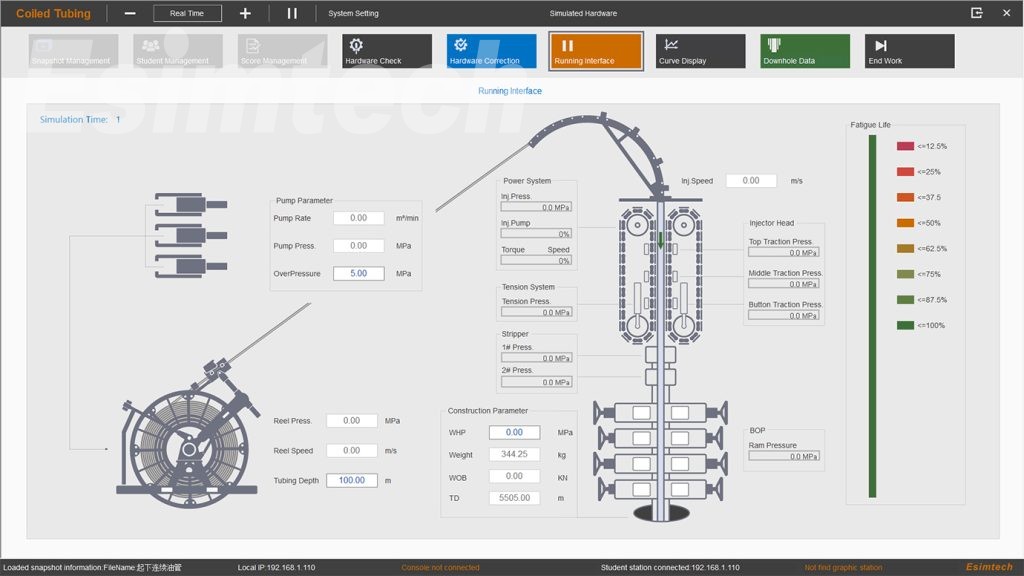

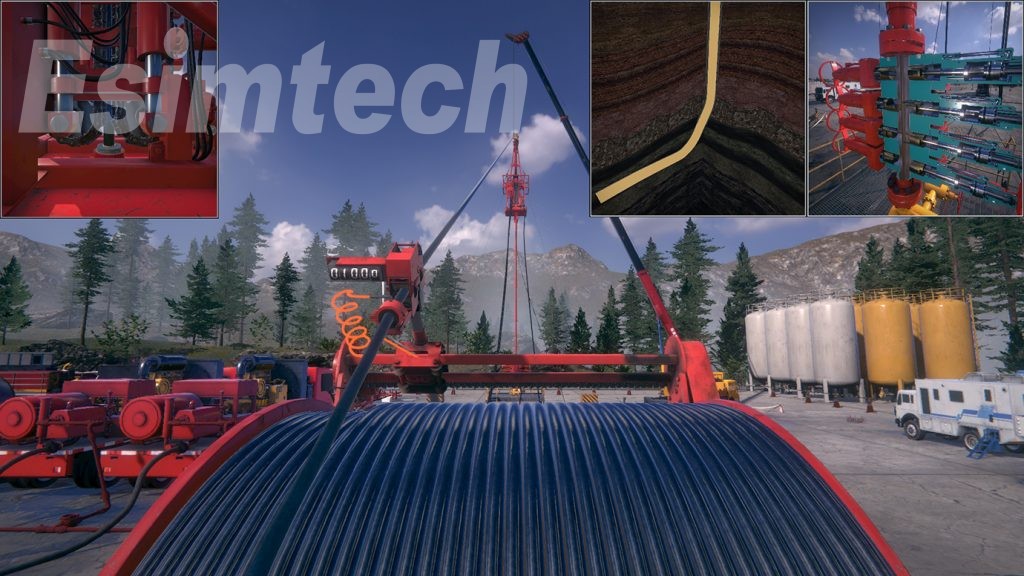

There are abundant mathematical models to simulate various parameters in coiled tubing operation, such as circulation pressure, tubing weight, WOB, tubing speed, as well as the relations between these parameters, to reach the same effect of the real coiled tubing operation. The parameters can be set freely in the system, such as coiled tubing parameter, tubing parameter, screw pump parameter, BOP parameter, well structure, etc. which makes the training more targeted. The system can also simulate common downhole accident during coiled tubing operation, and instructor can insert the accident at any time. Through the phenomenon, trainees judge and handle the accident, so as to improve their skill of judging and handling accidents. The system software is non-sequence structure, and can simulate various operation of coiled tubing, which makes the system closer to reality. The site scene constructed by virtual reality technology, displayed through 3D animation, combined with vivid sound effect, makes up an immersive training environment.

The whole system consists of coiled tubing console, display system, graphics system and accessory software system. The system console is quite similar to the real coiled tubing console. The layout, operation method and parameter display of the console panel is exactly the same is real product. The hardware control adopts industrial PLC, which ensures the reliability of the system.

2. System Component

2.1 System main hardware

1) Coiled tubing console

Coiled tubing is as shown in the following figure.The control and display on the console are the same as the real coiled tubing device.It can simulate the control of injector,BOP,injector pressure adjusting,drum control,etc.According to the operation,the system displays parameters at real time,such as circulation pressure,tubing weight,wellhead pressure,injector pressure,injector motor pressure,injector pump pressure,stripper pressure,drum drive pressure,BOP system pressure,tubing drum pressure,injector chain pressure,etc.

2) System layout

System layout effect picture is as shown in the following figure:

3) System configuration and parameters

| Item | Configuration |

| Parameter computer | CPU:I5 or the same;Memory:16G;Hard disk:SSD 240G |

| Master control computer | CPU:I7 or the same;Memory:16G;Hard disk:SSD 240G |

| Graphic computer | CPU:I7orthe same;Graphic card:GTX1660 Super or the same;Memory:16G;Hard disk:SSD 240G |

| Graphic screen | 80-inch LCD screen |

| Sound effect system | Sound effect system:two-channel speaker,sound mixer,amplifier |

| Printer | HPprinter*1 |

| Equipment cabinet | Totem cabinet |

| Table and chair | Table*1;Chair*1 |

2.2 System Software

Master control software

1) Platform software module

2) Instructor console software module

3) Exercise system software module

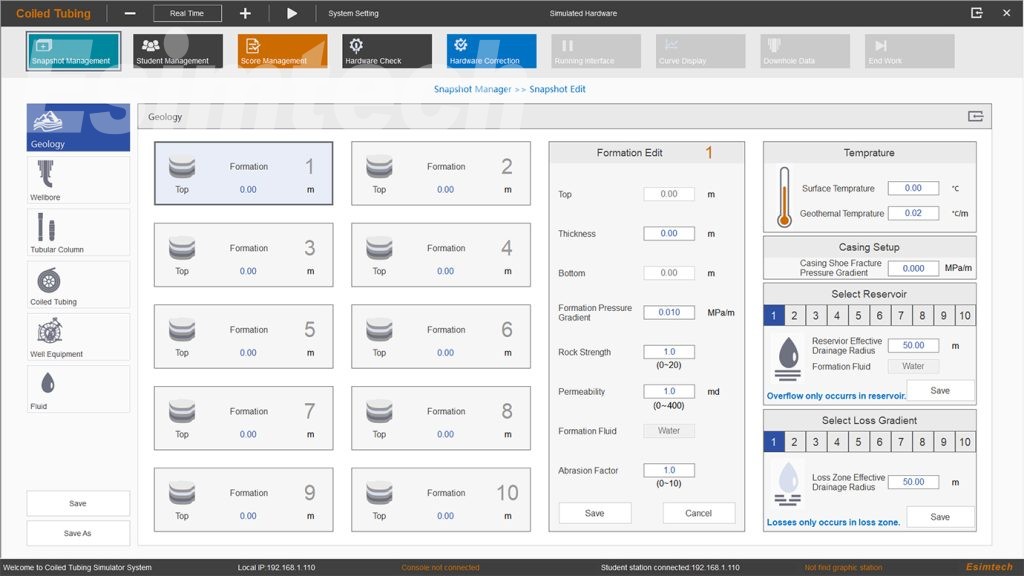

4) Snapshot managing module

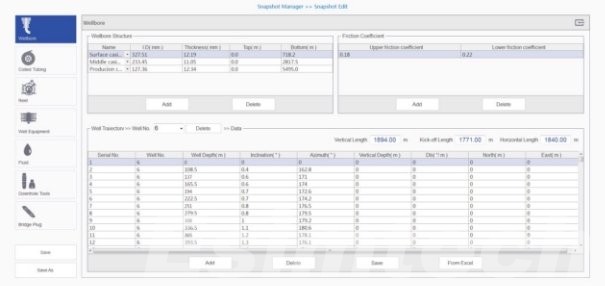

a) Well structure configuration

b) Coiled tubing configuration

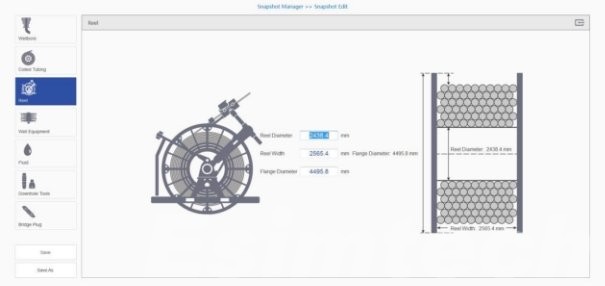

c) Reel configuration

d) Wellsite device configuration

e) Fluid configuration

f) Downhole tool configuration

g) Production string configuration

5) Problem and troubles software module

6) Sound effect control module software

7) Parameter display module

8) Device state display module

9) Fatigue lifespan analysis module

10) System diagnostic module

11) System correction module

12) Language shifting module

13) Unit shifting module

14) Student management and automatic scoring software module

Parameter software

1) State monitoring module

2) Data monitoring module

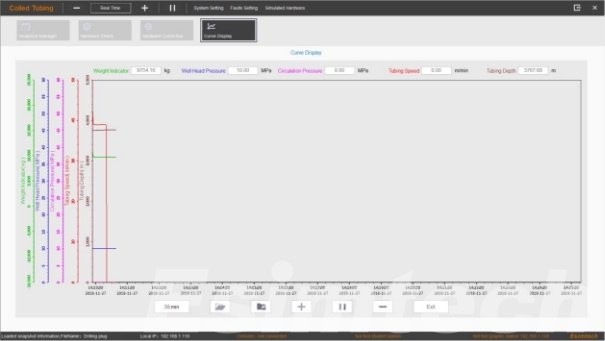

3) Curve view module

4) Lifespan curve module

5) Unitselecting module

6) Operation command module

Graphics software

1) 3Dscenario displaying module

2) Injector perspective displaying module

3) Reel perspective displaying module

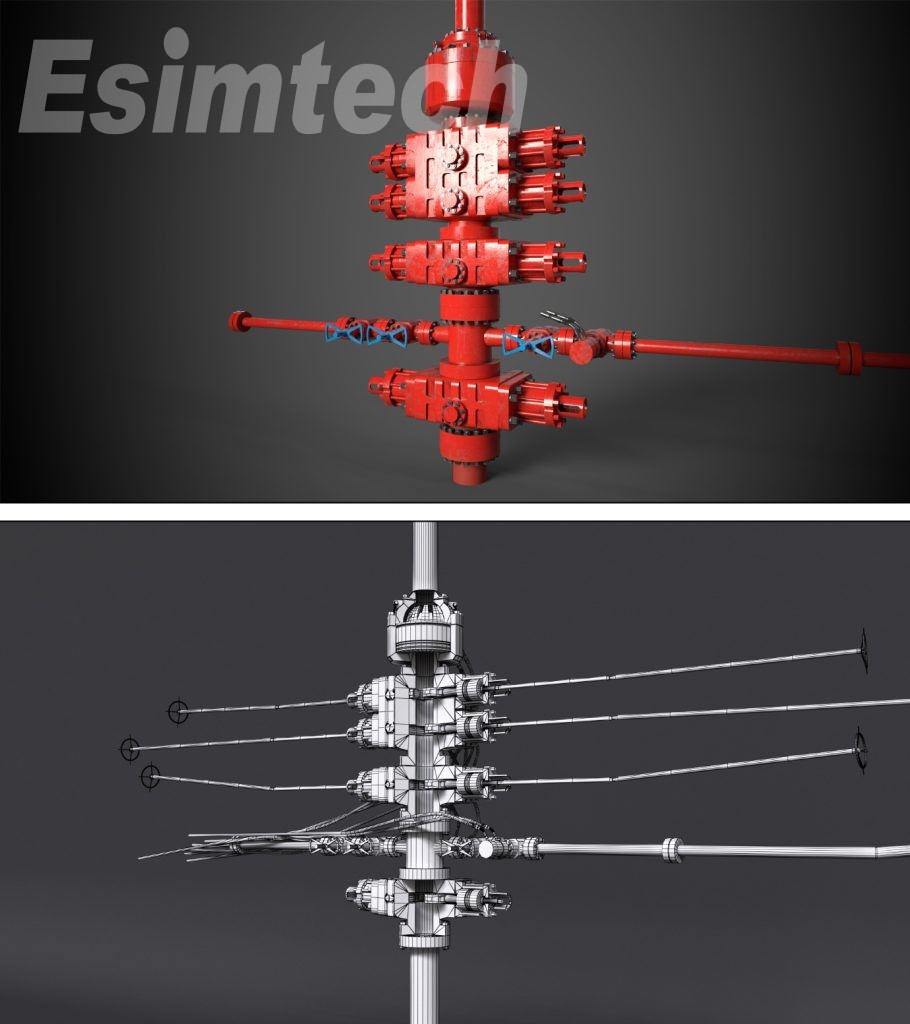

4) BOP perspective displaying module

5) Stripper perspective displaying module

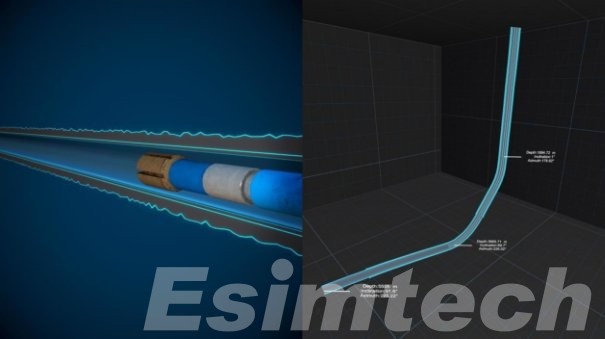

6) Well trajectory displaying module

7) Downhole tool displaying module

8) Problem phenomenon and treatment displaying module

2.3 FunctionsandFeatures

1) This simulation training system takes real coiled tubing system as prototype. The levers, meters and switches are the same as those on real equipment.

2) The system adopts non-sequence simulation software structure, with no restriction on operation sequence, which simulates the mode and function of real coiled tubing console completely. Operator can operate the system arbitrarily as operating the real equipment.

3) The system provides the function of loading one snapshot, and complete various operation. Through rational setting of well condition snapshot, students can practice items such as running and pulling coiled tubing, open and close BOP, adjust injector pressure, etc. in one snapshot.

4) Parameters can be set freely. Instructor can set various parameters freely, such as coiled tubing parameter, screw pump parameter, tubing parameter, device parameter, etc. Instructor can set various parameters according to a real well condition, and system device, and setup corresponding well condition snapshot, making the training process closer to real site, just as training on a real well.

5) The system provides accidents setting functions. Instructor can insert common accident at any time during operation. Through the changes of parameters and graph, students can judge the accidents. The accidents include coiled tubing leakage, stripper leakage, coiled tubing stuck, coiled tubing speed loss, coiled tubing collapse, etc.

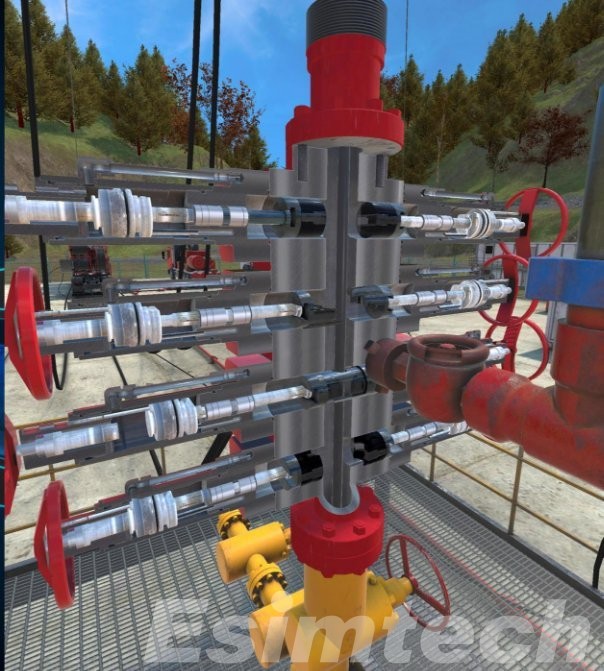

6) 3D animation simulates site scene. The animation I the system displays downhole view, surface device state and device working principle, etc. The scenes can be displayed by shifting and splitting the screen, such as wellhead injector BOP view, coiled tubing operation cabinet view, downhole view and sewage pit view, etc.

7) The system provides vivid sound effect. The system can simulate various sound effect. And the sound can start and stop according to operation, working condition and graph.

8) Automatic scoring function. The system can give score to students’ operation and their mistake automatically.

9) The system provides complete student management function, managing student information, operation item, scores, etc.

10) Important parameters can be displayed in the form of plots to show the change trend, in order to make students judge downhole condition and accident according to plots.

11) Flexible training process control, can pause the exercise at any time.

12) The system provides both metric unit and imperial unit.

13) The system provides Chinese and English language selection.

14) The scores and plots can be printed.

2.4 Current Training Items

1) Pulling and running tubing

2) Engine control operation

3) Reel control operation

4) Injector control operation

5) BOP control operation

6) Stripper control operation

7) Drilling bridge plug

8) Sand washing

9) Gas lift discharging

10) Judge and handleofdownhole accidents and troubles

- Coiled tubing leaking

- Stripper leaking

- Coiled tubing fracture

- Coiled tubing collapse

- Coiled tubing stuck

- Coiled tubing blocked

- Dynamic unit failure

- Coiled tubing speed loss

3. Main Technical Parameters and Operation Environment

3.1 TechnicalParameters

1) Power:110~220V/50~60Hz AC

2) Power consumption:<6000W

3.2 Operation Environment

1) Area:≥10*8.5m

2) Separate system power from light power.

3) Operation temperature:0℃~30℃

4) Relative humidity:<90%

4. Program Running Interface

The coiled tubing simulation training system is designed according to the international general equipment, equipped with a set of operation consoles, and displaying operation scene through 3D animation.

This system provides training on well logging, stimulation, workover, drilling and accident handling. It consists of an operation console, 3D animation display system, parameter auxiliary console and instructor station. The optional devices include choke manifold, choke console, auxiliary truck and production tree.

System Features

- Human-computer interactive, operable hardware, vivid graph, and lifelike sound effect

- Highly simulating the operation that cannot be carried out by real equipment training

- Intelligent scoring, fair assessment

- Powerful software functions, friendly interface, easy to learn and use

- Strict mathematical model, satisfy actual technology requirement

Parameters

| Power supply: | 110~220V/ 50~60 Hz AC |

| Power consumption: | < 6000 Watt |

| Working temperature: | 0℃~30℃ |

| Average time between malfunction: | ≥5000 hours |

Training Items

- Pulling and running tubing

- Engine control operation

- Reel control operation

- Injector control operation

- BOP control operation

- Stripper control operation

- Drilling bridge plug

- Sand washing

- Gas lift discharging

- Judge and handle of downhole accidents and troubles:

- Coiled tubing leaking

- Stripper leaking

- Coiled tubing fracture

- Coiled tubing collapse

- Coiled tubing stuck

- Coiled tubing blocked

- Dynamic unit failure

- Coiled tubing speed loss

System Components

Why Choose Us?

- Reality

- Highly realistic 3D scene display

- Service

- Timely and considerate after-sale service

- Simulation

- The appearance design, system layout, operation method and parameter display of the console panel is exactly the same as the real equipment.

F&Q

- What new petroleum simulations and features are you working on?

Esimtech has been committed in study and developing a petroleum engineering simulation training system for about 30 years, and has a series of independent intellectual property rights. Our simulators are widely used in many training companies with good feedbacks. To keep pace with the international standard and demand, Esimtech is now studying and developing MPD simulator, where some achievement has been reached.

- Why is your simulator better than other simulators I’ve used in the past?

With the mission of “Assist training, reduce accidents and benefit the society”, Esimtech have been doing their best to design, develop and service every simulator. Esimtech simulator has its features as strictness, reliability, realisticness, lifelikeness. Problems and incident playback function enables trainees to experience troubles for any time which helps trainees to better master the skills of judging and handling of common troubles.

- Do you have any certifications?

Esimtech drilling and well control simulator has been approved by IWCF and IADC.

Since establishment, Esimtech has obtained a series of independent intellectual property rights, including invention patents in China and abroad.

Esimtech was granted as “High-tech Enterprise”, and has been awarded the third prize of “Science and Technology Progress”.

Esimtech has also obtained the certificates of ISO 9001, ISO14001 and ISO45001.