Common Drilling Problems in Shale Formations and How to Solve Them

With the continuous increase in the production of shale gas and shale oil, the drilling operations are more complicated in terms of engineering challenges than those in the case of conventional formations. The aforementioned difficulties arise due to the inherent characteristics of shale formations, i.e., low porosity, low permeability, high anisotropy, and giving with respect to pressure control and as a result of the aforementioned reasons the decision on control of the well is difficult to make.In actual operations, many drilling accidents are not caused by equipment failures, but rather result from insufficient judgment of the formation response, unclear understanding of pressure windows, or improper emergency handling. Therefore, systematically identifying common problems in shale drilling and formulating response strategies in advance are the key to reducing non-productive time (NPT) and improving safety.

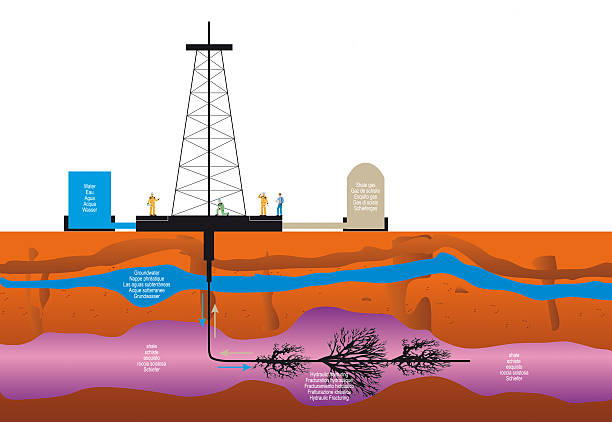

Key Characteristics of Shale Formations And Their Impact On Drilling

Before delving into specific issues, it is crucial to understand the engineering characteristics of the shale formation itself:

- Strong anisotropic stress distribution: There are significant differences in wellbore stability in different directions.

- High water sensitivity: An unreasonable mud system can easily lead to hydration and sloughing of the wellbore wall.

- Natural fractures and microcracks development: This increases the risks of leakage and pressure fluctuations.

- Narrow density window: A slight mistake can easily trigger well surges or leakage.

These characteristics determine that shale drilling places higher demands on parameter control, real-time judgment, and personnel experience.

Common Drilling Problems in Shale Formations

Wellbore instability

This is one of the most common problems in shale drilling. The main underlying causes are as follows:

- The water-based drilling fluid undergoes hydration reaction with shale clay minerals, causing the rock to expand;

- During the drilling process, the stress distribution in the formation changes, and brittle shale cannot withstand the stress changes and fractures;

- The mud density is insufficient, unable to balance the formation pressure and difficult to support the wellbore wall.

Wellbore instability will directly lead to wellbore collapse, well diameter expansion, and subsequently result in mud leakage, drill string jamming. The subsequent wellbore repair work is not only time-consuming but also incurs high downtime costs, seriously affecting the drilling progress.

Wellbore shrinkage and wellbore collapse

In long horizontal shale wells, the problems of wellbore shrinkage and wellbore collapse are particularly prominent. The formation mechanisms mainly include continuous creep of shale, accumulation of debris on the wellbore wall, and poor return flow of drilling cuttings.

These situations not only make it difficult for directional tools to pass through and hinder the running of casing, but also may pose risks for subsequent completion operations.

Leakage

Although the overall permeability of shale formations is relatively low, the natural fractures within the shale, the induced fractures generated during drilling, and the excessively high mud pressure are the main causes of leakage. Additionally, poor quality of the mud cake and the inability to effectively seal the pores of the wellbore walls can also exacerbate the leakage of mud.

Leakage not only results in a significant waste of mud, increases material costs, but also may cause damage to the formation, affect the subsequent oil and gas production capacity, and more likely mask the signals of well blowouts. If the leakage is severe and not dealt with in time, it may also trigger environmental risks.

Drill string stuck

Drill string stuck can be mainly classified into two types:

- One is pressure difference stuck, where due to the difference between the mud pressure and the formation pressure, the drill string is tightly pressed against the mud cake on the well wall;

- The other is mechanical stuck, which is mostly caused by the accumulation of rock debris from the well wall collapse, or the expansion and contraction of shale that narrows the wellbore.

Once drill string stuck occurs, it not only delays the construction schedule, but also requires expensive salvage operations. In extreme cases, it may even lead to well abandonment, resulting in huge economic losses.

Traditional Engineering Solutions

To address the aforementioned issues, the industry has developed a series of mature engineering approaches:

- Solution for wellbore instability: Optimize the wellbore trajectory, avoid the direction of adverse stress, select an appropriate inhibitory drilling fluid system, control ROP (rate of penetration), and reduce the exposure time of the wellbore wall

- Countermeasures for wellbore narrowing and wellbore collapse: Improve the efficiency of wellbore cleaning, reasonably design the rheological properties of the drilling fluid, and strengthen the monitoring of friction during the tripping-in and tripping-out processes

- Solution for leakage: Precisely control the density of the drilling fluid and the pump speed, reasonably use leak stopper materials (LCM), and monitor the changes in wellhead and bottomhole pressure in real time

- Prevention measures for drill string sticking: Optimize the filtration loss performance of the drilling fluid, reduce unnecessary stationary time, and reasonably control the bottomhole pressure difference

Well Control Challenges in Shale Drilling

In shale formations, the core challenge of well control lies not in typical sudden accidents, but in the ambiguous signals and difficult judgments. The main challenges are:

The formation often has a narrow safe density window, and a minor adjustment in the drilling fluid density may trigger complex situations downhole;

The invasion of formation fluids (Kick) and the elastic effect of the wellbore (Ballooning) are extremely similar in pressure response, making it difficult to quickly and accurately distinguish them;

Moreover, the complex pressure dynamics downhole further increases the probability of misjudgment.

This has led to the well control decisions for shale wells shifting from “ensuring correct operation” to a more critical “whether the correct and unique judgment can be made at the right time”.

The Auxiliary Role of Drilling And Well Control Simulators In Shale Drilling

In shale drilling, wellbore instability, leakage, and pressure anomalies often overlap, placing higher demands on the judgment and operational capabilities of on-site personnel. Besides engineering design and on-site monitoring methods, drilling and well control simulators serve as an important auxiliary tool to enhance personnel’s understanding and ability to cope with complex operating conditions.

Through highly realistic simulation models, drilling and well control simulators can recreate key equipment, operational procedures, and downhole pressure changes during drilling, allowing trainees to intuitively experience the impact of different operations on wellbore condition and well control safety in a risk-free environment. Specifically designed for shale drilling, typical scenarios such as wellbore instability, leakage, and pressure fluctuations within narrow density windows can be set up to help personnel identify early abnormal signals and understand their causes, thereby reducing the possibility of misjudgment and operational errors.

Conclusion

The problems in shale formation drilling have the characteristics of complex causes, mutual influence, and significant amplification effect. By deeply understanding the formation characteristics, adopting targeted engineering measures, and complementing with systematic technical training and simulation exercises, the drilling team can effectively reduce risks, minimize non-productive time, and enhance the overall operational safety and efficiency.