Commonly Overlooked Well Control Risks in Drilling Operations and How to Address Them

In oil and gas drilling operations, well control has always been the core aspect of safety management. Although the well control theory, operation norms, and equipment system are already quite mature, from the global accident statistics and review results, major accidents such as well surges and well blowouts still occur repeatedly. A common issue that deserves attention is that many accidents are not caused by a complete lack of well control knowledge, but rather by the neglect or underestimation of certain key risks.

This article, based on the mainstream safety management practices in the industry and the on-site drilling experience, starts from the "engineer's perspective" and systematically reviews the well control risks that drilling engineers are most likely to overlook in their actual operations, and provides corresponding improvement ideas and solutions.

Why Are Well Control Risks Often Overlooked?

Drilling operations are inherently characterized by high intensity, long duration, and concurrent multiple processes. Engineers on-site often need to simultaneously focus on drilling efficiency, equipment condition, operation rhythm, and cost control. In such an environment, as long as the downhole parameters "appear normal", well control risks are often regarded as controllable and even temporarily ignored.

Moreover, well control risks have obvious concealment and lag properties. Many dangers do not immediately manifest in extreme abnormal forms but accumulate gradually through subtle data changes. When these early signals are not promptly identified, the subsequent response window will rapidly narrow, and the risk level will increase exponentially.

Common Accident Risks In Drilling Sites

According to industry safety statistics, the main risks in drilling sites are concentrated in the following categories:

- Fire and explosion risks. Leakage of flammable gases, accumulation of static electricity, and faults in electrical equipment, when the well control fails, can easily be amplified, causing serious consequences.

- Heavy equipment and mechanical risks. When drilling rigs, hoisting systems, and pump units are operating under high loads, any abnormalities can not only cause personal injury but also affect the normal response of the well control system.

- Environmental and working condition risks. Harsh weather, offshore working conditions, and high-temperature and high-pressure environments all increase the complexity of well control operations.

- Chemical and toxic gas risks. If additives in drilling fluids or geothermal gases (such as H₂S) are not managed properly, they will directly threaten personnel safety.

These risks are often intertwined with well control issues, giving the accidents a distinct systemic character.

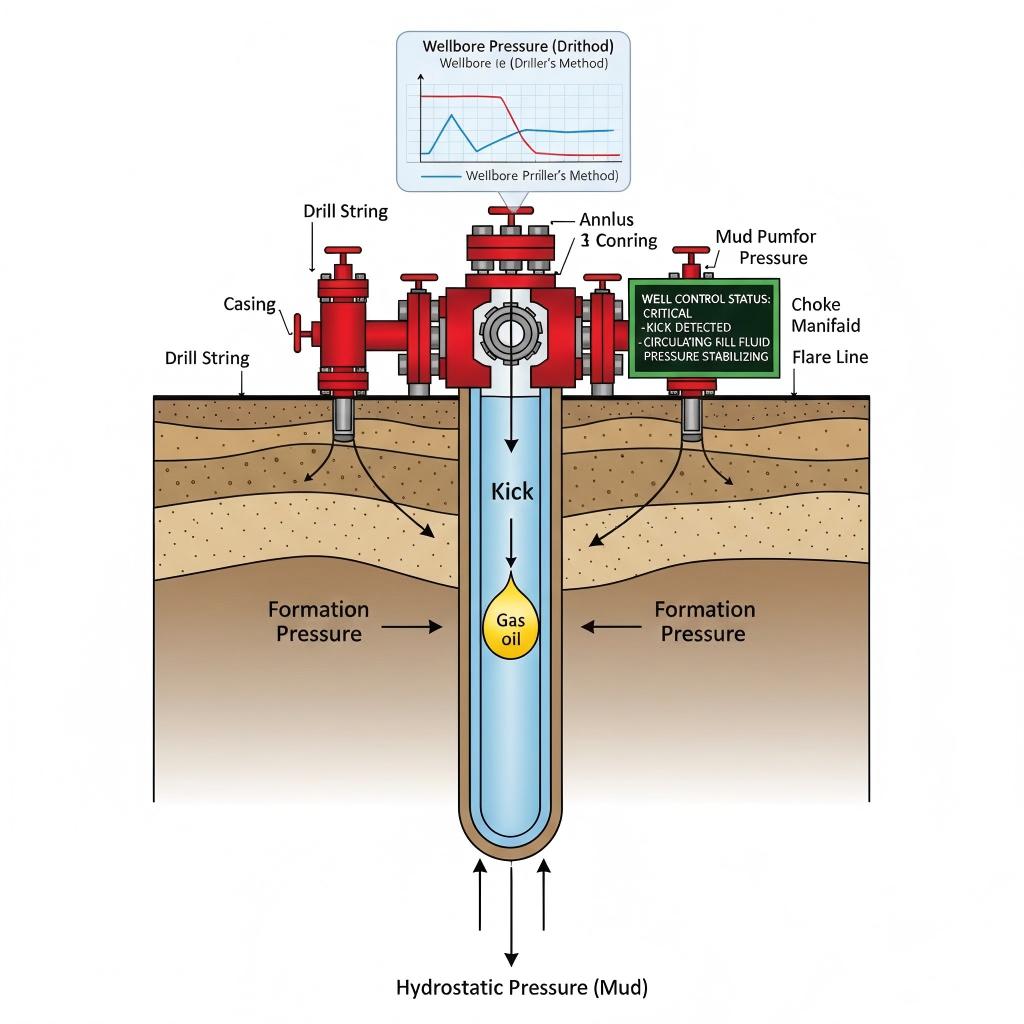

From an engineering perspective, the essence of well control is maintaining a dynamic balance between wellbore pressure and formation pressure. This balance relies on the coordinated efforts of the drilling fluid system, well control equipment, monitoring systems, and personnel decision-making.

Once this balance is disrupted, whether it's formation fluid intrusion into the wellbore or excessive pressure leading to formation fracturing, a chain reaction will occur. Therefore, well control is not the responsibility of a single link, but a systemic engineering project that spans the entire drilling lifecycle.

Key Well Control Risks That Drilling Engineers Most Easily Overlook

1. Formation Pressure Perception Bias

Formation pressure prediction is the foundation of well control design, but it inherently involves unavoidable uncertainties. Some engineers rely too heavily on pre-drilling models during construction, neglecting the importance of real-time data in correcting predictions.

Slight anomalies in pump pressure, return flow, or well fluid level are often interpreted as wellbore caliper changes or operational fluctuations, rather than potential pressure anomalies. This "rationalized explanation" easily masks the true risks.

2. Dynamic Imbalances in Drilling Fluid Control

Drilling fluid density is often considered a key indicator of well control, but in actual operations, factors such as changes in equivalent circulating density (ECD), leakage, and temperature and pressure effects are equally important.

If engineers focus only on static design values and ignore pressure changes during circulation, they may unknowingly weaken well control capabilities. These risks often accumulate slowly but erupt under specific operating conditions.

3. Well control equipment reliability is overestimated

While well control equipment such as blowout preventers (BOPs) have high safety redundancy, this does not mean they will respond perfectly in all situations. Aging equipment, inadequate maintenance, or insufficient testing can all lead to delays in response at critical moments.

In some incidents, the equipment did not completely fail, but rather "reacted too slowly," thus missing the optimal control opportunity.

4. Insufficient Comprehensive Identification of Drilling Parameter Anomalies

Modern drilling sites possess a wealth of real-time data, but without systematic parameter correlation analysis, this data can become mere noise.

For example, synchronized changes in drilling pressure, torque, and pump pressure often reflect changes in the downhole pressure environment more effectively than a single parameter. Ignoring this correlation reduces the effectiveness of well control early warning systems.

5. Insufficient Emergency Response Capabilities

Well control incidents often occur in high-pressure, fast-paced environments, placing extremely high demands on engineers' judgment and execution abilities. Teams lacking practical training are prone to hesitation in decision-making or deviations in process execution at critical moments.

Well Control Risk Management And Control Strategies

Establish a systematic risk assessment mechanism

Through closed-loop management of hazard identification, risk assessment, and control measures, well control risks are proactively addressed in the planning and design stages, rather than reactively responding after anomalies occur.

Strengthen Well Control Culture and Team Collaboration

A well control culture emphasizes that "everyone has the right and obligation to raise risks." Risk identification becomes a part of daily work through pre-shift meetings, toolbox meetings, and other methods.

Enhancing Practical Skills Through Simulation and Analogization

Compared to purely theoretical training, well control simulation exercises based on real-world working conditions are more effective in improving engineers' sensitivity to and ability to handle abnormal signals. For example, through drilling and well control simulation systems, engineers can repeatedly practice key scenarios such as abnormal formation pressure, well kick identification, and well shut-in operations, thereby significantly reducing reaction time in real-world operations.