Comparing Common Well Intervention Techniques: Wireline vs. Coiled Tubing vs. Snubbing

Maintaining the health and productivity of oil and gas wells throughout their lifespan is crucial. Well intervention techniques play a vital role in achieving this goal. These techniques involve accessing the wellbore downhole to perform various operations, ranging from data gathering and diagnostics to cleaning, stimulation, and equipment deployment or retrieval. Selecting the right intervention technique for a specific job depends on several factors, and understanding the strengths and limitations of each method is essential. Here, we will explore three common well intervention techniques: wireline, coiled tubing, and snubbing.

Well Intervention Techniques: A Brief Overview

Wireline

This method utilizes a thin, high-strength cable (wireline) to lower specialized tools downhole. The wireline itself acts as a conduit for transmitting data and electrical signals between the surface and downhole tools. Wireline interventions are ideal for gathering downhole data such as pressure, temperature, and fluid samples. They are also used for deploying small tools for light intervention procedures like operating valves, perforating formations to enhance wellbore connectivity, and retrieving downhole tools or debris. Wireline’s simplicity and relatively low cost make it a popular choice for many routine wellbore operations. However, its reach is limited by the length of the cable, typically reaching depths of a few kilometers. Additionally, wireline is not suitable for deploying heavy equipment or large volumes of fluids due to the limitations of the cable’s strength and weight capacity.

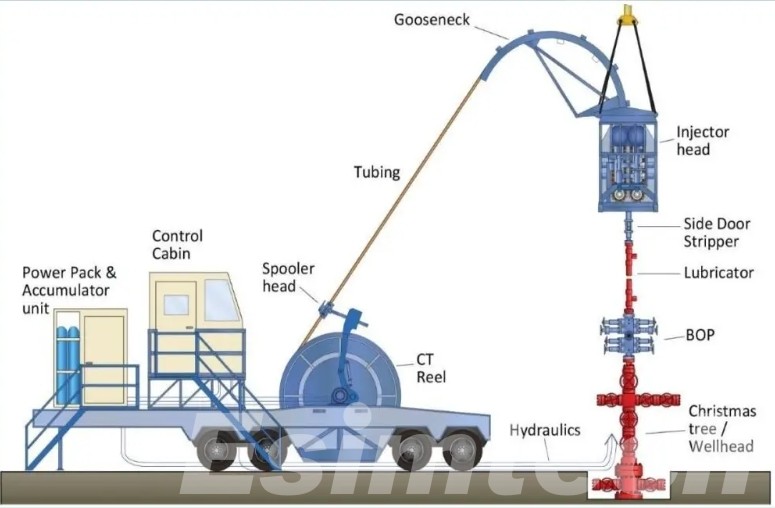

Coiled Tubing

Unlike wireline, coiled tubing utilizes a continuous spooled pipe that can be deployed directly into the wellbore. This continuous pipe, typically made of high-strength steel, offers several advantages over wireline. Coiled tubing allows for deployment of a wider variety of tools and fluids for various operations. Common applications include wellbore cleaning (removing deposits or debris), stimulation treatments (acidizing to remove formation damage or hydraulic fracturing to create new flow paths), and downhole equipment deployment or retrieval (pumps, packers, etc.). Coiled tubing offers greater reach compared to wireline and can handle larger volumes of fluids, making it suitable for more complex well intervention procedures. However, coiled tubing operations are generally more complex and expensive than wireline due to the specialized equipment required for deployment and handling of the continuous pipe.

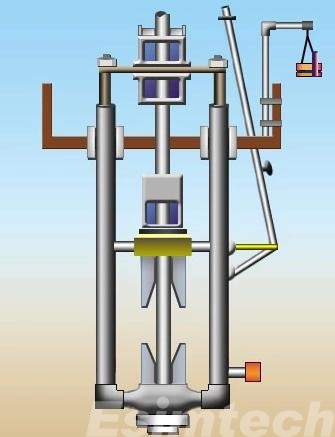

Snubbing

This technique is specifically designed for interventions in highly deviated or horizontal wells where traditional wireline or coiled tubing deployment might be challenging. In these wells, the friction between the intervention string (wireline or coiled tubing) and the wellbore can become significant, hindering smooth deployment and retrieval. Snubbing units address this challenge by using a combination of hydraulic cylinders and elevators. These elevators act like a mechanical hand, gripping and guiding the intervention string as it is lowered or raised into the wellbore. The hydraulic cylinders provide controlled movement and manage the weight of the intervention string, allowing for precise deployment and retrieval of tools and equipment even in complex well geometries. While snubbing provides excellent reach and wellbore access in highly deviated or horizontal wells, it is a highly specialized and expensive operation compared to wireline or coiled tubing due to the complexity of the snubbing unit and the expertise required for its operation.

Detailed Comparison of Wireline, Coiled Tubing, and Snubbing

The following table summarizes the key differences between these three well intervention techniques:

| Feature | Wireline | Coiled Tubing | Snubbing |

| Applications | Data gathering, diagnostics, light intervention | Cleaning, stimulation, deployment/retrieval (fluids & tools) | Highly deviated/horizontal wells (cleaning, deployment/retrieval) |

| Advantages | Cost-effective, simple setup, good for data acquisition | Versatile, good reach, large volume fluid handling | Excellent reach in complex wells |

| Limitations | Limited depth reach, light intervention capability | More complex setup, higher cost | Expensive, specialized equipment required |

| Typical Well Types | Vertical, deviated | Vertical, deviated, horizontal | Highly deviated, horizontal |

Factors to Consider When Choosing a Technique

The choice of a well intervention technique depends on a nuanced evaluation of several key factors:

- Type of intervention required: This is the primary consideration. Analyze the specific task at hand (data gathering, cleaning, stimulation, etc.) and identify the tools or fluids necessary for the operation. Wireline is ideal for data acquisition and light intervention procedures, while coiled tubing excels at deploying fluids and tools for cleaning, stimulation, and equipment handling. Snubbing is best suited for complex well geometries where reach and precise control over the intervention string are critical.

- Wellbore geometry: The well’s deviation (vertical, deviated, horizontal) significantly impacts the choice of technique. Wireline and coiled tubing can handle vertical and deviated wells effectively. However, for highly deviated or horizontal wells with high friction, snubbing becomes the preferred option due to its ability to manage the weight of the intervention string and prevent excessive friction that could damage the wellbore or equipment.

- Depth of the intervention: Each technique has limitations regarding depth reach. Wireline depth is restricted by the cable length, while coiled tubing can reach greater depths. Snubbing operations typically target shallower well sections due to the complexity and cost involved.

- Cost-effectiveness: Well intervention is an investment, and cost optimization is crucial. Wireline is generally the most cost-effective option, followed by coiled tubing. Snubbing is the most expensive due to the specialized equipment and expertise required. Finding the right balance between cost and the effectiveness of the intervention for the desired outcome is essential.

Availability of equipment and expertise: The availability of the necessary equipment and personnel with the specific expertise for each technique needs to be factored in. Wireline units and personnel are widely available, while coiled tubing and snubbing operations

Conclusion

Wireline, coiled tubing, and snubbing each offer unique advantages and limitations for well intervention. Understanding these differences is crucial for selecting the most effective and cost-efficient technique for a specific task. As well intervention technologies continue to evolve, new methods and advancements will further enhance our ability to maintain and optimize well performance throughout the production cycle.