The Critical Role of Wireline Logging in Oil and Gas Exploration and Production

In the intricate world of oil and gas exploration and production, wireline logging stands as a fundamental technique employed to gather crucial subsurface data. This article aims to illuminate the essence of wireline logging, elucidating its methodologies, significance, applications and the crucial role of simulation technology in enhancing wireline logging operations.

What is Wireline Logging

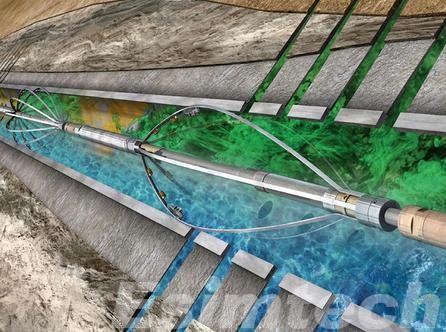

At its core, wireline logging entails the deployment of specialized tools and sensors down a wellbore via a sturdy cable or “wireline.” These tools meticulously measure and record various properties of the subsurface formations, providing invaluable insights into the composition, structure, and fluid content of the reservoir.

Key Methodologies Commonly Used in Wireline Logging

The methodologies of wireline logging encompass a diverse range of tools and techniques tailored to extract crucial information from subsurface formations.

1. Gamma Ray Logging

- Principle: Utilizes the natural gamma radiation emitted by formations to identify lithology and evaluate the presence of radioactive elements, such as uranium and thorium, which are indicative of specific rock types.

- Application: Helps in identifying shale formations, delineating lithological boundaries, and providing insights into the sedimentary sequence.

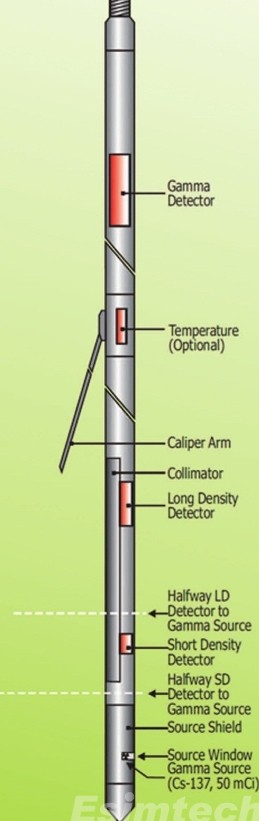

2. Density Logging

- Principle: Measures the density of formations by detecting the attenuation of gamma rays as they pass through the rock.

- Application: Provides information about rock composition, porosity, and density variations, aiding in reservoir characterization and evaluation of fluid saturation.

3. Neutron Porosity Logging

- Principle: Determines porosity by measuring the hydrogen content of formations using a neutron source and detector.

- Application: Enables estimation of reservoir porosity, fluid saturation, and pore volume, crucial for assessing hydrocarbon reserves and reservoir quality.

4. Sonic Logging

- Principle: Measures the travel time of acoustic waves through the rock to infer properties such as porosity, lithology, and mechanical integrity.

- Application: Helps in evaluating rock mechanical properties, identifying formation boundaries, and assessing wellbore stability.

5. Resistivity Logging

- Principle: Measures the electrical resistivity of formations to evaluate fluid saturation, lithology, and hydrocarbon potential.

- Application: Provides insights into formation water salinity, hydrocarbon saturation, and reservoir connectivity, guiding reservoir evaluation and production optimization efforts.

6. Caliper Logging

- Principle: Measures the diameter of the wellbore using mechanical or electromagnetic sensors.

- Application: Assists in assessing wellbore integrity, detecting changes in hole size, and identifying borehole obstructions or washouts.

7. Formation Pressure Testing

- Principle: Determines formation pressure gradients and fluid properties by conducting pressure tests using wireline tools equipped with pressure sensors and packers.

- Application: Enables assessment of reservoir pressure, pore pressure, and fluid contacts, crucial for well planning, drilling, and production operations.

Challenges and Innovations in Wireline Logging

Wireline logging, despite being a cornerstone technique in the oil and gas industry, faces several challenges. However, continuous innovations have led to the development of solutions that enhance efficiency, accuracy, and safety.

Here’s a chart outlining the challenges and corresponding innovations in wireline logging.

| Challenges | Innovations |

| Tool Reliability | Advanced logging tool design and materials Enhanced sensor technologies Improved downhole electronics |

| Data Quality Assurance | Real-time data transmission Enhanced telemetry systems Quality control measures and calibration procedures |

| Operational Safety | Automation of logging operations Robotics for tool deployment Remote-controlled tools Safety training and protocols |

| Data Interpretation Complexity | Advanced data processing algorithmsMachine learning and AI for data interpretationIntegrated logging suites for comprehensive data acquisition |

| Environmental Challenges | Development of tools resistant to extreme conditions (temperature, pressure, corrosive environments) Implementation of environmental monitoring systems |

| Cost Constraints | Development of cost-effective logging toolsOptimization of logging operations to reduce rig time and operational expenses |

| Regulatory Compliance | Ensuring compliance with industry standards and regulations Implementation of safety and environmental protocols |

The Role of Simulation Technology in Wireline Logging

1. Training and Education

- Simulation technology offers realistic training environments for logging engineers and technicians to hone their skills in deploying logging tools, interpreting data, and troubleshooting potential issues.

- Trainees can experience simulated wellbore conditions, varying geological formations, and challenging operational scenarios, preparing them for real-world logging operations.

2. Operational Planning and Optimization

- Well logging simulators allows logging teams to plan and optimize logging programs by simulating different logging tool configurations, logging parameters, and wellbore conditions.

- Engineers can simulate logging tool runs in virtual wellbores, predicting tool responses, optimizing tool placement, and identifying potential logging risks or challenges before executing operations in the field.

3. Tool Development and Testing

- Simulation technology facilitates the development and testing of new logging tools and technologies in a virtual environment, enabling engineers to assess tool performance, reliability, and compatibility with existing logging systems.

- Engineers can simulate tool deployment, data acquisition, and tool interactions with various formation types, validating design concepts and identifying potential design flaws or improvements.

4. Risk Mitigation and Safety Training

- Simulation scenarios can replicate hazardous logging conditions and emergency situations, allowing logging personnel to undergo safety training and practice emergency response procedures in a controlled environment.

- By simulating potential logging risks, such as tool sticking, cable failure, or unexpected formation pressures, teams can develop risk mitigation strategies and improve safety protocols.

5. Data Interpretation and Analysis

- Simulation software can aid in data interpretation and analysis by providing tools for visualizing and processing simulated logging data in real-time.

- Engineers can practice data interpretation techniques, identify logging anomalies, and extract meaningful insights from simulated logging data, enhancing their ability to interpret actual logging data during field operations.

6. Cost Reduction and Efficiency Improvement

- By simulating logging operations in a virtual environment, companies can reduce the costs associated with field testing, equipment rental, and downtime, while optimizing operational efficiency.

- Simulation technology allows for iterative testing and refinement of logging procedures, leading to more efficient logging operations, reduced non-productive time, and ultimately, cost savings.

Conclusion

By providing insights into reservoir characteristics, wellbore stability, and production performance, wireline logging enables operators to optimize drilling, completion, and production operations, ultimately maximizing hydrocarbon recovery and economic returns from oil and gas reservoirs.

Simulation technology plays a crucial role in enhancing wireline logging operations by providing a safe, cost-effective, and efficient means of training, planning, and optimizing logging procedures.