What Is Dual Completion in Oil & Gas? A Quick Introduction

In today's ever-evolving oil and gas industry, maximizing production efficiency is very important. In recent years, dual completion technology has become a popular innovation. This technology allows operators to produce from two zones in a single wellbore, thereby increasing production efficiency while reducing overall drilling costs.

What are the Basics of Dual Completion

Dual completion is a sophisticated well-completion technology that allows operators to produce and access two different hydrocarbon-bearing zones through a single wellbore. Instead of having to drill and complete two separate wells, operators can save huge capital and reduce surface footprint by installing equipment in the well to isolate and control the production of each zone individually. This technique is especially attractive in stacked reservoirs, offshore situations where platform space is scarce, or old fields where hitherto bypassed pay can be reactivated at no new drilling.

Essentially, dual well completion aims to:

- Optimize Reservoir Contact: By producing two distinct intervals—generally ones with different pressures, fluid properties, or driving mechanisms—operators can optimize overall production and delay the onset of coning or water breakthrough.

- Enhance Operational Flexibility: Independent control of each zone enables production levels, artificial lift regimes, or injection schemes to be optimized on a zone-by-zone basis. Such a level of control preserves drawdown balance, controls pressures, and prolongs well life.

- Reduced Operating and Capital Costs: Two completions in a single well minimize rig time, tubular and casing cost, and surface facility. Over the life of the field, these cost savings often offset the added complexity and greater up-front investment of the dual completion equipment.

Effectiveness relies on safe isolation between the two productive areas, robust monitoring, and rigorous flow control. Operators must carefully account for reservoir properties, anticipated pressure regimes, and forecasted production profiles to select the most appropriate completion design.

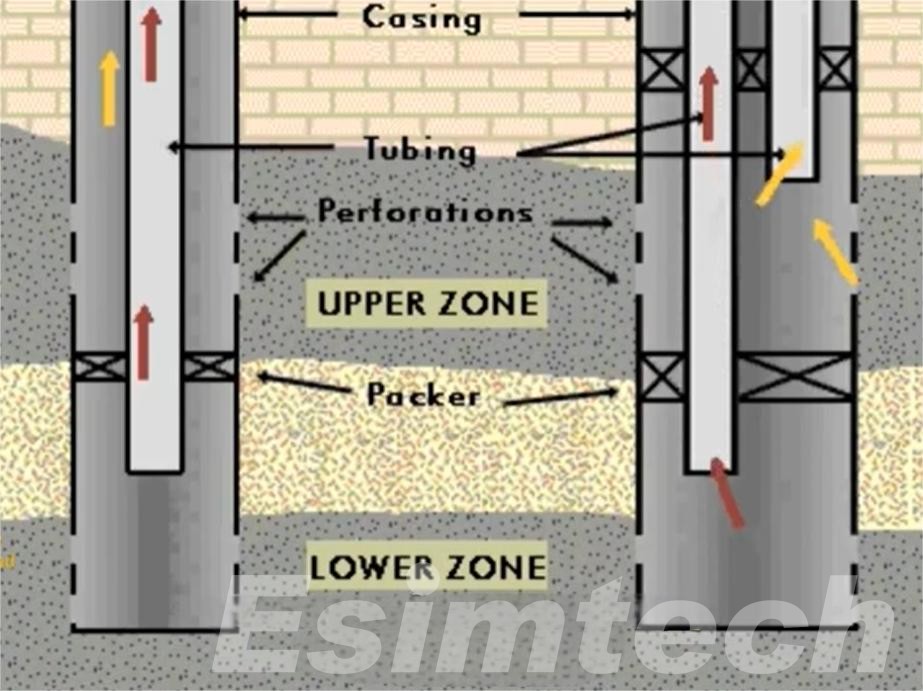

Key Items & Equipment

- Tubing Strings: In most instances, two separate tubing strings are run within the casing to carry fluids from one zone separately to the surface.

- Isolation Packers: Inflatable or compression-set packers separate individual intervals from each other, avoiding fluid communication.

- Sliding Sleeves / Control Valves: Downhole sleeves allow operators to open, close, or throttle each zone as per the requirements, facilitating real-time production management.

- Y-Tools: In case electrical submersible pumps are installed in dual completions, Y-Tools separate flow paths and enable pump installation within a single string while maintaining flow in the second.

- Monitoring Sensors: Pressure and temperature sensors located over and under packers provide information for monitoring, enabling immediate action if conditions are different from design requirements.

Through the integration of these factors, dual completion systems provide a balance between efficiency and versatility that makes them an anchor method in today's multi-zone reservoir exploitation.

What are the Types of Dual Completions

Dual completions are not uniform. Depending on reservoir conditions, well design, and production targets, there are many variations of dual well completion systems used. Each of these is tuned for performance, control, and economics in specific field conditions. Let's have a close look at the main types of dual completions and how they differ in operation and application.

1. Dual String Dual Zone (DSDZ) Completion

This is the most common form of dual completion. Two separate tubing strings are run in a shared casing, one for each individual reservoir zone. Isolation is done with packers between zones, and production from each zone separately returns to the surface. This configuration has excellent control and monitoring capabilities and is optimal for zones of varying pressure regimes or fluid types.

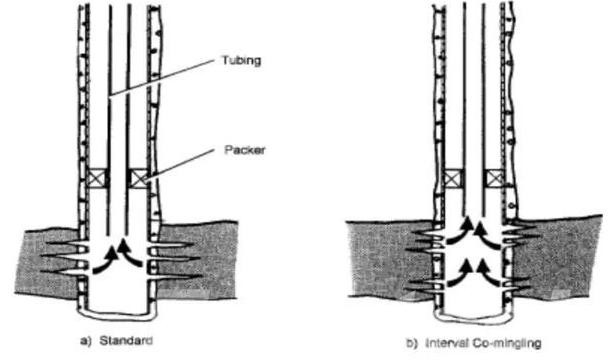

2. Single String Selective Completion

In this setup, one string of tubing delivers access to several zones, with flow control devices such as sliding sleeves or downhole valves at each interval. The operator can open or shut specific zones selectively but cannot produce from both at the same time. It is cost-effective in situations where simultaneous production is not required or where one zone will be produced later during the life of the well.

3. Commingled Dual Completion

Two zones are both produced from a single tubing string without mechanical isolation in a commingled system. Both reservoir fluids are commingled downhole and are produced to surface in tandem. This is simpler and cheaper but could complicate reservoir management if the zones are very different in pressure or fluid type.

4. Dual Injection Completion

Although not production-focused, this kind of design allows injecting water, gas, or chemicals into two different zones from a single well. It is generally used in enhanced oil recovery (EOR) operations or pressure maintenance over multilayered reservoirs.

All dual completion types have their own advantages and compromises, and the selection should be consistent with the reservoir scheme, well objectives, and entire long-term developing program.

Single vs. Dual Completion in Oil & Gas

In well completion designs, the operators have a critical decision: tie back one completion to one reservoir interval or utilize a dual completion to produce several zones within a single wellbore. The choice influences operational complexity, production flexibility, and field economics.

Single Completion is the standard design for reservoirs with only one productive interval to be developed. It is a straightforward, inexpensive solution with only one tubing string and limited isolation components. It limits production, though, to one zone and thus in fields with more than a single possible reservoir, multiple wells may be required to economically exploit the hydrocarbon reserves.

Dual Completion, on the other hand, involves the placement of two or more production intervals within the same well. With the use of additional equipment such as packers, sliding sleeves, and dual tubing strings, operators can individually control and monitor each reservoir zone. This method offers more control because the operators can alter the production parameters for each zone based on different reservoir conditions. While the initial cost and sophistication are higher, dual completion will result in more ultimate recovery and reduced total development expense, particularly in bound or multi-zone areas.

Below is a key differences summary sheet:

| Feature | Single Completion | Dual Completion |

| Number of Zones | One zone | Two zones |

| Tubing Setup | Single tubing string | One or two tubing strings |

| Operational Complexity | Simpler, lower equipment demands | Higher complexity with extra components |

| Flexibility | Limited production control | Independent control of each zone |

| Cost Implications | Lower upfront costs; may require additional wells for multi-zone reservoirs | Higher initial investment, but offers long-term savings in multi-zone developments |

By analyzing reservoir characteristics and production targets, operators can decide on the completion type that best meets their economic and operational objectives.

What are the Applications of Dual Completion

Dual completion systems are successful solutions in different conditions of the oil and gas field. Their ability to maximize production, reduce the cost of drilling, and manage complex reservoirs makes them highly useful in onshore and offshore developments. The uses of dual completion in the industry are as follows:

- Multi-Zone Reservoirs: Where hydrocarbons are found in a series of stacked units, dual completions give a two-productive zone exposure from one wellbore. This eliminates the need for drilling individual wells, reducing capital expense and surface disturbance.

- Offshore Fields: In offshore conditions where there is limited space and spare well slots, double well completions maximize the resources recovered from fewer wells. This is particularly useful in fixed platforms or floating production systems where there is limited capacity.

- Improved Oil Recovery (IOR): Dual completions in IOR operations make injection and production possible at the same time. For example, water or gas can be injected in one zone and production from another zone to ensure optimum reservoir pressure and sweep efficiency.

- Reservoir Monitoring and Management: Dual completions enable independent monitoring of pressure, temperature, and flow in each of the zones. All this detailed information enables better reservoir management and decision-making over the well life.

- Brownfield Developments and Recompletion Projects: Dual completions are utilized in brownfield developments to reopen existing wells and access bypassed or unproduced zones. It helps increase recovery without the drilling of new wells, offering enhanced return on investment.

- High-Cost Area Cost Optimization: In high-cost drilling and completion regions—such as arctic or deepwater operations—dual completions are one way of maximizing production per well and improving project economics.

These applications serve to illustrate the versatility and strategic importance of dual well completion systems in modern oilfield development.

Wrapping Up

In summary, dual completion is a cost-effective method of multi-layer production in a single well. By using dual tubing, packers and dedicated wellhead devices, operators can increase production while minimizing operating costs.

Whether in offshore oil fields, stacked reservoirs or gas lift applications, dual completions provide flexibility and improve recovery. As technology advances, intelligent dual completion technology with real-time monitoring capabilities is becoming more and more effective.