ESIM-DEP1 Drilling Emergency Practice Training Platform

- Preciseness

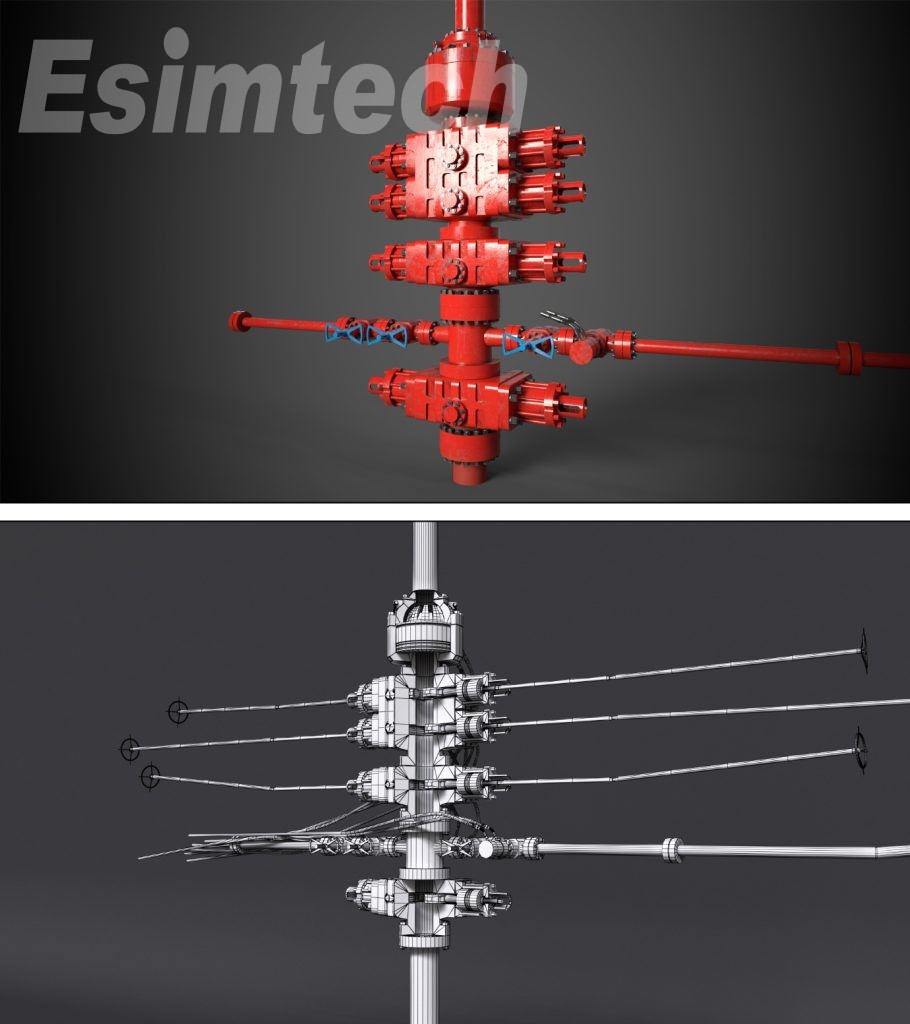

- Precise mathematical and physical model

- Reliability

- Stable and reliable software and hardware

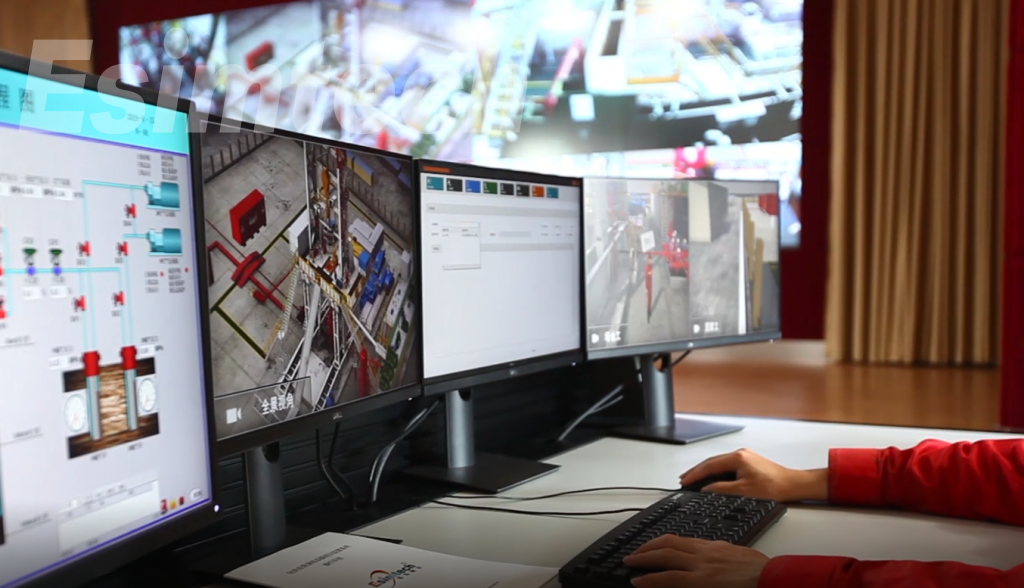

- Reality

- Highly realistic 3D scene display

The original purpose of designing an emergency practice training system is to impress the emergency handling process deeply on students’ mind, and therefore enables them to form conditioned reflex. In this way, when students encounter accidents on real sites such as blow-out, explosion, H2S leakage, etc., they will be enabled to overcome the stress and carry out the correct emergency handling measurement.

Training Items

Emergency handling and escaping when blowout out of control

- Drilling operation (Hard shut-in)

- Tripping in and out drill pipe (Hard shut-in)

- Tripping in and out drill collar (Hard shut-in)

- Barren hole operation (Hard shut-in)

- Drilling operation (Soft shut-in)

- Tripping in and out drill pipe (Soft shut-in)

- Tripping in and out drill collar (Soft shut-in)

- Barren hole operation (Soft shut-in)

Emergency handling and escaping when H2S leakage and poisoning

- Drilling operation (Hard shut-in)

- Tripping in and out drill pipe (Hard shut-in)

- Tripping in and out drill collar (Hard shut-in)

- Barren hole operation (Hard shut-in)

- Drilling operation (Soft shut-in)

- Tripping in and out drill pipe (Soft shut-in)

- Tripping in and out drill collar (Soft shut-in)

- Barren hole operation (Soft shut-in)

Emergency handling and escaping when there is fire and explosion

- Drilling operation (Hard shut-in)

- Tripping in and out drill pipe (Hard shut-in)

- Tripping in and out drill collar (Hard shut-in)

- Barren hole operation (Hard shut-in)

- Drilling operation (Soft shut-in)

- Tripping in and out drill pipe (Soft shut-in)

- Tripping in and out drill collar (Soft shut-in)

- Barren hole operation (Soft shut-in)

Comprehensive deduction

- Drilling operation (Hard shut-in)

- Tripping in and out drill pipe (Hard shut-in)

- Tripping in and out drill collar (Hard shut-in)

- Barren hole operation (Hard shut-in)

- Drilling operation (Soft shut-in)

- Tripping in and out drill pipe (Soft shut-in)

- Tripping in and out drill collar (Soft shut-in)

- Barren hole operation (Soft shut-in)

Emergency handling skills

- Fire

- Electric shock

- Mechanical injury

- Self and mutual medical aid

F&Q

- Why is the simulator necessary for the oil and gas industry?

Since the beginning of the 20th century, simulators have been used in different industries as tools to train and to facilitate the growth of the operators of the machinery. This type of training is, without a doubt, one of the most effective ways to mitigate labor risks, develop the skills needed, and increase productivity.

In the oil and gas industry, accidents happen from time to time, such as blowout, H2S leakage, fire, explosion, machinery injuries, etc. Working in the oil and gas field is of high risk. According to statistics, almost 36% of these accidents were caused by mistakes in operation. Sufficient pre-post training is essential. A simulator makes this possible, which provides a virtual training environment, for new staff the get familiar with the working environment, site scene, and operation devices in advance. With the simulator, new staff can also experience the common incidents which may occur in real operations, and learn to judge and handle emergencies. So that in real work, most of the accidents can be a judged or avoided in an early stage, and therefore reduces risks and increase production.

- Why is your simulator better than other simulators I’ve used in the past?

With the mission of “Assist training, reduce accidents and benefit the society”, Esimtech have been doing their best to design, develop and service every simulator. Esimtech simulator has its features as strictness, reliability, realisticness, lifelikeness. Problems and incident playback function enables trainees to experience troubles at any time which helps trainees to better master the skills of judging and handling common troubles.

- Do you have any happy clients or testimonials about your simulator?

“Creating value for customers”, which is always emphasized in our company. With this original intention, Esimtech Company develops simulators with high quality and provides timely and enthusiastic services. For all these years, the products and services provided by Esimtech are highly praised by our customers.

- Can you do custom work for my specific rig, company, or field?

Esimtech provides customization service, which is the biggest feature of the company. Esimtech has a strong production team skilled at programming and animation production. Both hardware and software can be customized to comply with the real situation.

- Do you have any certifications?

Esimtech drilling and well control simulator has been approved by IWCF and IADC.

Since its establishment, Esimtech has obtained a series of independent intellectual property rights, including invention patents in China and abroad.

Esimtech was granted as “High-tech Enterprise”, and has been awarded the third prize of “Science and Technology Progress”.

Esimtech has also obtained the certificates of ISO 9001, ISO14001 and ISO45001.