Innovative Use of Hydraulic Fracturing for Well Intervention

In the realm of oil and gas extraction, maintaining and enhancing well productivity is critical in the oil and gas extraction industry. When a well’s performance begins to decline or encounters issues, various intervention techniques are employed to enhance production or address problems. One such method gaining prominence is hydraulic fracturing, traditionally associated with well completion in unconventional reservoirs like shale. However, hydraulic fracturing techniques are now being innovatively utilized for well intervention purposes, transforming the industry’s approach to improving reservoir performance and recovery. This article explores the innovative application of hydraulic fracturing for well intervention as well as its benefits, challenges, and simulation technology used in optimizing its performance.

Understanding Hydraulic Fracturing for Well Intervention

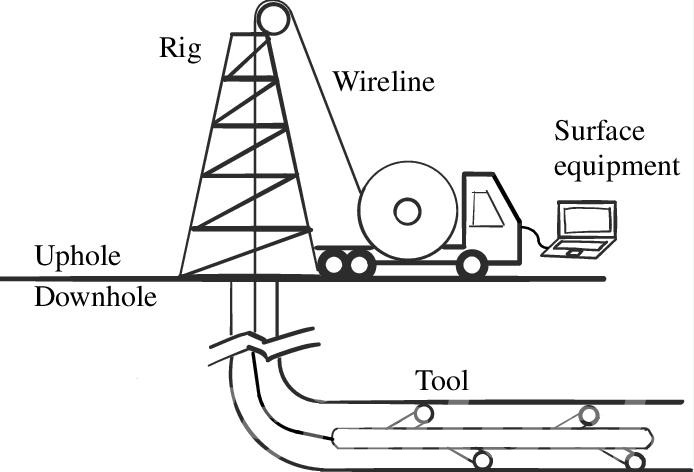

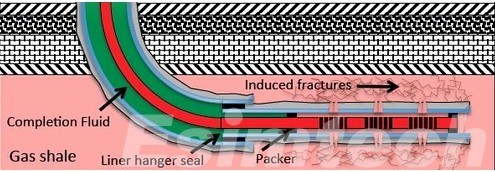

Hydraulic fracturing, sometimes known as fracking, is the process of injecting high-pressure fluid into a wellbore to shatter underground rock formations. These cracks, which are often filled with proppants to keep them open, allow hydrocarbons to flow more easily to the wellbore, improving production rates. While hydraulic fracturing has been predominantly used during well completion, its application for well intervention purposes involves stimulating existing wells to improve or restore productivity.

Key Techniques and Applications of Hydraulic Fracturing for Well Intervention

1. Refracturing Existing Wells

Refracturing, also known as re-stimulation, is the process of applying hydraulic fracturing techniques to existing wells with declining production. By injecting high-pressure fluids into the wellbore, operators can generate new fractures or reopen old ones, boosting production from previously unproductive areas. Refracturing can significantly improve hydrocarbon recovery from aged reservoirs and extend the economic life of wells.

2. Remediation of Formation Damage

Hydraulic fracturing techniques are used to repair formation damage caused by things like drilling fluids, fines migration, and scale deposition. Creating fractures in the reservoir formation allows operators to bypass damaged zones, increase reservoir connectivity, and restore well production. Remedial hydraulic fracturing treatments are designed to address specific formation concerns while improving reservoir performance and hydrocarbon recovery.

3. Zonal Isolation and Control

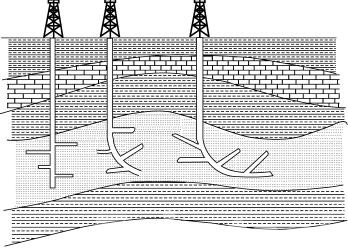

Hydraulic fracturing is employed for zonal isolation and control during well intervention operations. By creating fractures in targeted intervals along the wellbore, operators can isolate or bypass problematic zones, control fluid flow, and optimize reservoir drainage. Zonal isolation ensures that hydraulic fracturing treatments are confined to the desired intervals, preventing communication between different reservoir zones and maximizing treatment effectiveness.

4. Reservoir Connectivity Enhancement

Hydraulic fracturing techniques are used to enhance reservoir connectivity and drainage efficiency. By creating complex fracture networks that extend beyond the immediate vicinity of the wellbore, operators improve fluid flow pathways and increase contact with productive zones. Enhanced reservoir connectivity maximizes hydrocarbon recovery rates, particularly in heterogeneous or compartmentalized reservoirs, and enhances the overall performance of the well.

5. Production Enhancement

Hydraulic fracturing interventions are aimed at enhancing production rates and optimizing well performance. By stimulating reservoirs with high-pressure fracturing treatments, operators increase the permeability of the formation, allowing hydrocarbons to flow more freely to the wellbore. Production enhancement techniques may involve multi-stage fracturing, where multiple zones along the wellbore are sequentially fractured to maximize hydrocarbon recovery.

6. Water and Gas Shut-off

Hydraulic fracturing techniques can be used to prevent unwanted water or gas output from wells. Operators can efficiently prevent undesirable fluids or gasses from entering the wellbore by generating fractures near water or gas-producing zones and injecting specialist materials such as chemical sealants or polymer gels. Water and gas shut-off procedures increase well productivity, lower operating costs, and lessen the environmental dangers associated with water and gas production.

7. Sand Control

Hydraulic fracturing is used for sand management to prevent sand production while maintaining well integrity. Sand control treatments entail injecting proppants or resin-coated particles into cracks produced in the reservoir formation to prevent formation sand from migrating into the well bore. Sand control enhances well productivity, reduces equipment wear, and minimizes the risk of formation damage associated with sand production.

Benefits of Hydraulic Fracturing for Well Intervention

| Benefits | Explanation |

| Increased Well Productivity | Stimulates flow of hydrocarbons from reservoir formations, enhancing production rates. |

| Extended Economic Life of Wells | Revitalizes mature or declining wells, maximizing recovery of hydrocarbon reserves. |

| Enhanced Reservoir Management | Selectively stimulates specific zones, and maximizes reservoir drainage efficiency. |

| Improved Hydrocarbon Recovery Rates | Accesses untapped reserves, enhances reservoir connectivity, and maximizes recovery. |

| Operational Flexibility and Adaptability | Adjusts fracturing parameters to optimize performance, and address reservoir complexities. |

| Environmental Benefits | Reduces water usage, lowers greenhouse gas emissions, and employs advanced technologies for sustainable resource development. |

| Economic Advantages | Increases production rates, reduces operational costs, and maximizes revenue generation and profitability. |

Challenges Associated with Hydraulic Fracturing for Well Intervention

| Challenges | Explanation |

| Technical Complexity | High-pressure fracturing operations require specialized equipment and expertise, posing technical challenges in well design, execution, and monitoring. |

| Operational Risks | Fracturing operations carry inherent risks such as equipment failure, fluid loss, wellbore integrity issues, and induced seismicity, necessitating careful planning and execution. |

| Environmental Concerns | Potential environmental impacts include water usage, chemical additives, surface and groundwater contamination, and induced seismic events, prompting regulatory scrutiny and public concern. |

| Regulatory Compliance | Compliance with stringent regulations governing hydraulic fracturing operations, including permits, reporting requirements, and environmental standards, can pose logistical and financial challenges. |

| Cost Implications | Hydraulic fracturing interventions involve significant upfront costs for equipment, materials, and personnel, as well as ongoing expenses for monitoring, compliance, and risk management. |

Simulation Technology Used in Optimizing Hydraulic Fracturing for Well Intervention

Simulation technology provides engineers valuable insights into the behavior of reservoirs and the effectiveness of fracturing treatments.

1. Reservoir Modeling

Advanced reservoir simulation software is used to represent the reservoir’s geological characteristics, such as porosity, permeability, and fluid properties. Engineers can optimize treatment design by simulating reservoir behavior under various operating circumstances.

2. Fracture Modeling

Hydraulic fracturing simulators are used to model fracture propagation inside reservoir rock. These simulators use complex mathematical models, such as the Finite Element Method (FEM) or the Discrete Element Method (DEM), to forecast fracture geometry, dimensions, and spread patterns. Engineers can use fracturing factors including injection rate, fluid viscosity, and proppant concentration to optimize fracture design and enhance hydrocarbon recovery.

3. Fluid Flow Simulation

Computational Fluid Dynamics (CFD) software is used to simulate the flow of fluids within the wellbore and fractures. By modeling fluid behavior under different pressure and temperature conditions, engineers can optimize fluid placement, distribution, and diversion strategies to ensure effective fracture stimulation and reservoir drainage.

4. Geomechanical Modeling

Geomechanical simulators are employed to model the mechanical response of the reservoir rock to hydraulic fracturing treatments. These oil and gas simulators predict factors such as stress distribution, rock deformation, and induced seismicity, allowing engineers to assess the risk of fracturing-induced reservoir damage, casing failure, or unwanted fluid migration.

5. Production Forecasting

Integrated reservoir simulation models combine geological, geophysical, and engineering data to forecast future reservoir performance and production rates. By simulating fluid flow dynamics over time, engineers can assess the long-term effectiveness of hydraulic fracturing treatments, predict well decline rates, and optimize production strategies to maximize economic recovery.

6. Data Analytics and Machine Learning

Advanced data analytics and machine learning algorithms are increasingly being used to evaluate massive amounts of data generated by hydraulic fracturing operations. These techniques find patterns, trends, and correlations in reservoir and operational data, allowing engineers to optimize fracturing treatments, diagnose problems, and make data-driven decisions to improve well performance.

Conclusion

Hydraulic fracturing techniques, which are traditionally associated with well completion, are increasingly being used for well intervention, providing operators with innovative solutions to improve reservoir performance and increase hydrocarbon recovery. Hydraulic fracturing methods can be used to rejuvenate mature wells, enhance reservoir drainage, and unlock the full potential of existing assets. However, it is critical to address the accompanying problems responsibly, ensuring that fracturing operations are carried out safely, sustainably, and in accordance with regulatory standards.

Simulation technology plays a vital role in enhancing the efficiency, effectiveness, and safety of hydraulic fracturing for well intervention. Simulation tools enable operators to optimize fracturing treatments, mitigate risks, and maximize hydrocarbon recovery from oil and gas reservoirs.