What is Sidetracking Drilling in Oil and Gas

As a critical technique within the petroleum field, sidetracking drilling enables increased production, overcomes logistical challenges, and examines previously inaccessible geological formations and reservoirs. The approach is equally valuable in the event of a stuck drillpipe and in cases where new reservoirs need to be tapped into through existing wellbores. This article discusses the mechanics of sidetracking drilling, its significance in oil and gas operations, the various types, and its major applications.

How Sidetracking Drilling Works?

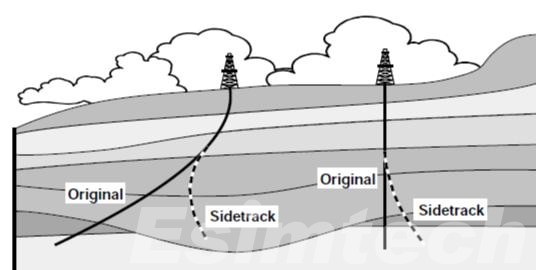

Sidetracking drilling is a method employed to excavate a new borehole from an existing well. This is done when the original well is rendered non-productive, faces an obstruction, or when there is a need to access a different segment of the reservoir. This process begins with the isolation, or plugging, of the lower section of the original wellbore. Thereafter, specialised instruments such as whipstocks and rotary steerable systems are employed to form a new pathway that departs from the original trajectory.

Geological targets can dictate whether the sidetrack is drilled at a predetermined angle or in a particular direction. Also, depending on the status of the well, sidetracking can take place in cased or open hole environments. In cased hole sidetracking, a window is milled in the casing and the drill bit is redirected.

This approach is a key component of sidetrack oil and gas operations, as it serves as a more economical option when compared to drilling a new well. It enhances the advantages of the existing infrastructure while simultaneously unlocking additional reserves or bypass problem zones.

What’s Role of Sidetracking Drilling?

In oil and gas operations, optimally balancing costs and risks while maintaining well performance can be achieved through sidetracking drilling. Unlike conventional drilling, which necessitates starting a well from the surface, sidetracking drilling utilizes existing wellbores alleviating the need to drill new wells, consequently increasing efficiency and prolonging the lifespan of fields.

- Reservoir optimization is one of the most important sidetracking drilling roles. Severely depleted mature wells often experience a significant drop in production. By enabling operators to drill laterally, sidetracking drilling enhances the ability to access additional hydrocarbons without incurring new well expenses. This is very advantageous in complicated layered formations which missed productive zones on initial drilling.

- Wellbore remediation is another important sidetracking drilling role. If wells sustain damages from casing failures, sand ingress, or stubborn tools, sidetracking can bypass the damages and restore production. This practice preserves infrastructure while preventing the costly challenge of well abandonment.

- Moreover, sidetracking facilitates exploratory drilling by allowing operators to test adjacent formations using existing wells. This approach greatly mitigates exploratory development risks while streamlining associated timelines.

- Lastly, sidetracking reduces the need for new vertical drilling locations. This reduces surface disturbance for new wells and associated drilling costs, and makes hydrocarbon extraction more environmentally sustainable.

Essentially sidetracking drilling increases asset value by improving recovery rate, resolving operational issues, and streamlining resource use.

What are the Types of Sidetracking Drilling?

Sidetracking drilling is a versatile technique widely used in the oil and gas industry to enhance production, resolve operational challenges, or extend the life of a well. Depending on the condition of the wellbore and the intended outcome, several types of sidetracking drilling methods are employed. Each approach has specific advantages, limitations, and ideal use cases.

Open Hole Sidetracking

Open hole sidetracking is carried out before any casing is set in the well. This method offers the greatest directional flexibility, allowing engineers to adjust the borehole path to target the most productive zones within a reservoir. Because there’s no casing to restrict movement, it is easier to achieve aggressive build angles and optimize reservoir contact. However, it requires meticulous wellbore management, as the uncased formation is more prone to collapse or instability, especially in soft or fractured rock formations. Drilling fluid properties and hole cleaning efficiency are critical in these operations.

Cased Hole Sidetracking

Cased Hole Completion

In this method, sidetracking is performed after the casing has already been set and cemented in the well. Engineers must first mill a window in the casing—typically using a whipstock and mill assembly—before deviating the wellbore in the desired direction. Cased hole sidetracking is frequently used in older or previously producing wells where new zones need to be accessed, or the existing wellbore is damaged. It provides better structural integrity and zonal isolation, making it suitable for wells in high-pressure or unstable formations. However, it limits flexibility in choosing sidetrack direction due to the fixed casing.

Whipstock Sidetracking

Whipstock Drilling

Whipstock sidetracking utilizes a wedge-shaped steel tool called a whipstock, which is set in the wellbore to guide the drill bit away from the original hole. The whipstock creates a defined angle that diverts the bit in a new trajectory. This technique can be used in both open and cased hole sidetracking and is especially valuable when precision is needed in steering the new borehole. It is commonly used in cased hole operations during re-entry projects or when bypassing stuck pipe or collapsed intervals.

Hydraulic Jetting Sidetracking

Hydraulic jetting is a more recent innovation in sidetrack oil well drilling. It uses high-pressure fluid jets to erode the rock and create a new borehole path without the need for mechanical drilling tools. This reduces tool wear and the risk of mechanical failure. Hydraulic jetting is ideal for initiating short-radius sidetracks in soft formations and can be performed relatively quickly and at lower cost. However, it is less effective in hard rock environments and typically used for targeted, shallow deviations.

What are the Applications of Sidetracking Drilling?

Sidetracking drilling is fundamental in prolonging the productivity and the value of oil and gas wells. Its uses are multidisciplinary and can be of great value in mature fields, problem wells, and in cost-sensitive environments. These are the most important and common uses of sidetracking drilling:

1. Recovering Stuck or Damaged Wells: This technique is mostly used to bypass a section of the well where drilling tools are either stuck or where the formation has collapsed. Operators prefer sidetracking over abandonment because it allows them to bypass stuck sections of the well and carry on with operations without losing significant time and cost.

2. Reaching Untapped or Bypassed Reservoirs: Sidetracks allow operators to access zones that are either overlooked in the initial drilling or are deemed uneconomical. With the aid of updated geological models, sidetracking facilitates the targeting of new reservoir compartments, in turn improving recovery.

Sidetracking Drilling onsite

3. Improving Output in Aging Fields: Often in older oil and gas fields, production is hindered by pressure depletion or inadequate reservoir connectivity. In these situations, sidetrack oil well drilling is very useful because it allows for the re-entry of previously drilled oil wells and extends their lifespans by drilling into more productive zones, therefore, removing the need for a new surface location.

4. Resourceful Development of Fields: Operators can also sidetrack new wells into previously drilled wells, which allows for the drilling of new wells in previously untapped zones. This is very useful in offshore or environmentally sensitive regions where surface access is limited or very expensive.

5. Tactical Re-Entry of Abandoned Wells: With the use of better seismic data and favorable market conditions, companies can re-enter and redirect drilling efforts into old or shut-in wells. Sidetracking these wells allows for the shifting of drilling efforts, therefore, extracting value from wells that are previously deemed uneconomic.

In all these situations, sidetracking drilling proves to be a flexible, economical, and technically effective solution for oil and gas production optimization.

Summary

Sidetracking drilling is a powerful and economical technique that adds to the constantly increasing recovery rates of oil and gas while also improving operational efficiency. It furthers operational optimization by forming additional wellbore from preexisting ones which allows sidestepping of barriers, accessing new reservoirs, and increasing the productive lifespan of aging wells. This technique has many bypass approaches including the open-hole sidetracking that aims to quickly gain access to the reservoir, and the more advanced cased-hole sidetracking aimed at wellbore remediation. Sidetracking, whether used strategically in field development or as a well-controlling emergency measure, is effective in increasing recovery of hydrocarbons while maintaining minimum environmental footprint and drilling expenditures. Such advanced methodologies are indisputably essential in contemporary hydrocarbon extraction, especially during challenging reservoir and wellbore conditions.