The Integration of Well Logging with Other Downhole Technologies

In the oil and gas industry, the exploration and production of hydrocarbons rely heavily on the accurate assessment of subsurface formations. Well logging, a crucial aspect of this process, involves recording and analyzing data from downhole measurements to evaluate geological formations, fluid properties, and reservoir characteristics. However, the traditional approach to well logging is evolving, driven by advancements in downhole technologies and the increasing demand for comprehensive data analysis. This article explores the integration of well logging with other downhole technologies, highlighting its transformative potential and the role of simulation technology in enhancing data interpretation.

What is Well Logging?

Well logging is a crucial technique used in the oil and gas industry to obtain detailed information about subsurface formations encountered during drilling operations. It involves the systematic measurement and recording of various physical properties of the rock formations, fluids, and other geological features surrounding a borehole. These measurements are essential for assessing reservoir characteristics, such as porosity, permeability, lithology, fluid content, and pressure, which are vital for reservoir evaluation, wellbore stability analysis, and hydrocarbon exploration and production.

Well logging tools, also known as logging tools or logging instruments, are lowered into the wellbore either during drilling or after completion, and they collect data continuously as they are pulled back to the surface. These tools can measure a wide range of parameters, including gamma radiation, electrical resistivity, acoustic velocity, neutron density, and magnetic susceptibility, among others. Each measurement provides valuable insights into the properties of the subsurface formations and helps geoscientists and engineers to characterize the reservoir and make informed decisions regarding well construction, production strategies, and reservoir management.

Well logging data is typically presented in the form of logs or plots, which graphically represent the variations in geological properties with depth along the borehole. Interpretation of these logs requires expertise and specialized software to analyze and extract meaningful information about the reservoir's composition, structure, and fluid content. Well logging plays a critical role in the entire lifecycle of an oil or gas well, from exploration and appraisal to production and abandonment, contributing to more accurate reservoir assessments, optimized drilling operations, and improved hydrocarbon recovery rates.

Key Downhole Technologies

In addition to traditional well logging methods, several key downhole technologies play crucial roles in enhancing the scope and accuracy of subsurface data acquisition in the oil and gas industry:

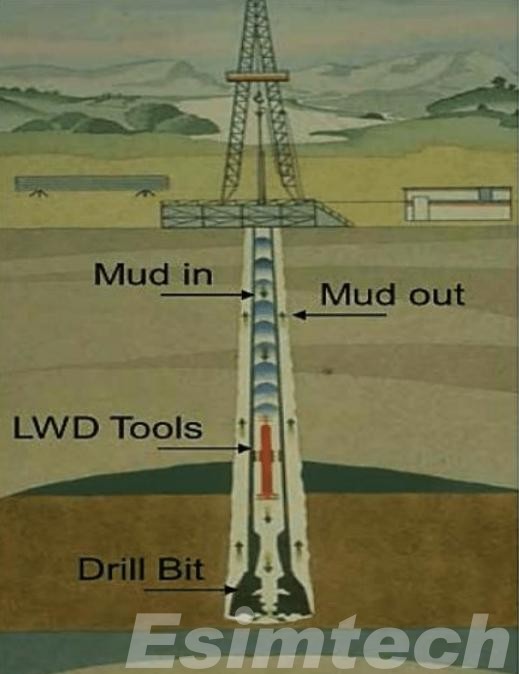

- Measurement While Drilling (MWD) and Logging While Drilling (LWD)

MWD and LWD technologies enable real-time data acquisition while drilling, providing operators with immediate insight into formation characteristics and drilling parameters. MWD tools incorporate sensors near the drill bit to measure parameters such as inclination, azimuth, and toolface orientation, allowing operators to steer the drill bit accurately. LWD tools, on the other hand, perform formation evaluation measurements, including gamma ray, resistivity, neutron porosity, and formation pressure, while drilling. These technologies eliminate the need for additional logging runs, enabling faster decision-making and more efficient drilling operations.

- Seismic Imaging

Seismic surveys are indispensable for imaging subsurface structures and geological formations. By generating and analyzing seismic waves sent into the Earth's subsurface, seismic imaging provides detailed images of subsurface features, such as faults, stratigraphy, and reservoir structures. This information aids in reservoir characterization, reservoir mapping, and identifying potential drilling locations for exploration and development wells. Advanced seismic imaging techniques, such as 3D seismic surveys and seismic inversion, further enhance the resolution and accuracy of subsurface imaging, enabling operators to make informed decisions about well placement and reservoir management.

- Fiber Optic Sensing

Fiber optic sensing technology involves deploying fiber optic cables along the wellbore to monitor various downhole parameters in real-time. These sensors use changes in light propagation within the optical fiber to measure temperature, pressure, strain, and acoustic signals along the wellbore. Fiber optic sensing provides continuous, distributed monitoring of downhole conditions, offering valuable insights into reservoir behavior, wellbore integrity, and production performance. By detecting changes in downhole conditions, such as fluid flow, temperature gradients, and mechanical stress, fiber optic sensing enables operators to optimize production strategies, prevent equipment failures, and enhance reservoir recovery.

These key downhole technologies complement traditional well logging methods by providing real-time data acquisition, detailed imaging of subsurface structures, and continuous monitoring of downhole conditions. By integrating these technologies into well construction and production operations, operators can improve drilling efficiency, optimize reservoir management, and maximize hydrocarbon recovery from oil and gas reservoirs.

The Power of Integration Well Logging with Other Downhole Technologies

While well logging provides valuable insights into formation properties, integrating it with other downhole technologies unlocks a more comprehensive understanding of the reservoir, enabling a holistic approach to reservoir characterization. Here's a deeper dive into how this integration empowers us to paint a clearer picture of the hidden world beneath the surface:

1. Refining Fluid Characterization:

Formation Testers: Well logging typically provides indirect measurements of fluid properties like saturation and type. Integrating these logs with data from formation testers allows for direct fluid sampling and pressure measurements. This in-situ data provides crucial information about the mobility and composition of the reservoir fluids, leading to more accurate reservoir characterization and improved evaluation of hydrocarbon potential.

2. Unveiling Reservoir Heterogeneity:

Imaging Tools: Wellbore images obtained through cameras or resistivity imaging tools offer unparalleled visual insights into the formation. Integrating these images with well logs allows for identifying subtle features like fractures, faults, and bedding planes that may not be readily apparent from logs alone. This detailed understanding of the reservoir's heterogeneity helps in optimizing well placement, targeting specific zones for production, and designing effective recovery methods.

3. Dynamic Reservoir Monitoring:

Production Optimization Tools: Integrating well logging data with real-time data from downhole flowmeters and pressure gauges creates a dynamic picture of the reservoir's performance. This allows for continuous monitoring of fluid flow, pressure changes, and reservoir behavior. By correlating production data with well logs, engineers can identify production issues, optimize choke settings, and adjust well completion strategies for improved production efficiency and recovery.

4. Building a Collaborative Network:

The integration of well logging with other downhole technologies goes beyond just data gathering. It fosters collaboration between different disciplines within the oil and gas industry. Geologists, reservoir engineers, and production specialists can work together, utilizing the combined information to develop a more comprehensive understanding of the reservoir and make informed decisions throughout the entire exploration and production lifecycle.

By harnessing the power of integration, we move beyond viewing well logging as an isolated technique. When combined with other downhole technologies, it becomes a powerful tool for unlocking the secrets of the reservoir, leading to more efficient and sustainable resource extraction.

Simulation Technology for Well Logging

Simulation technology plays a crucial role in enhancing the interpretation of integrated well logging data. Advanced computational models and algorithms simulate subsurface conditions based on the collected data, allowing for predictive analysis and scenario testing.

Here are the steps involved in a typical well-logging simulation process:

- Formation Modeling: The initial stage of the simulation process involves constructing a model of the subsurface formation surrounding the wellbore. This model incorporates key parameters such as formation conductivity, dielectric properties, and other relevant geological information. Utilizing inputs from well logs, seismic data, or other geological sources, the formation model provides a detailed representation of the subsurface environment.

- Specification of Logging Tools: Subsequently, the simulation specifies the parameters of the logging tools, encompassing factors such as frequency, waveform, and design intricacies. These specifications directly influence how electromagnetic waves behave as they traverse through the formation, thus impacting the resulting data acquired during logging operations.

- Propagation of Electromagnetic Waves: The simulator then undertakes the computation of electromagnetic wave propagation through the formation. This entails solving intricate mathematical equations that delineate the interaction between the waves and the geological formation, accounting for complexities in wave behavior and formation characteristics.

- Analysis of Signal Response: Following wave propagation calculations, the simulator determines the response of the logging tool to the electromagnetic waves penetrating the formation. This response is contingent upon both the specifications of the logging tool and the properties of the formation itself, providing crucial insights into the acquired data.

- Simulation of Well Logs: Ultimately, the simulation culminates in the generation of a simulated well log based on the outcomes of the previous steps. This simulated log mirrors the data that would be obtained through actual logging operations in the well. Such simulated logs serve various purposes, including the testing and validation of logging tool designs, the development of interpretation algorithms, and the evaluation of measurement sensitivities to diverse parameters.

By integrating simulation technology with well logging data, operators can:

- Predict reservoir performance: Simulate fluid flow dynamics, production profiles, and reservoir behavior to optimize production strategies and maximize hydrocarbon recovery.

- Evaluate reservoir uncertainty: Conduct sensitivity analysis and uncertainty quantification to assess the impact of geological uncertainties and input parameters on reservoir performance predictions.

- Optimize well placement and completion designs: Utilize simulation-based optimization techniques to optimize well placement, completion designs, and hydraulic fracturing strategies based on integrated well logging and downhole monitoring data.

Conclusion

The integration of well logging with other downhole technologies represents a paradigm shift in reservoir characterization and production optimization practices. By combining data from multiple sources and leveraging simulation technology, operators can achieve a more comprehensive understanding of reservoir properties and behavior, leading to more informed decision-making and optimized production strategies. As technology continues to advance, the integration of well logging with complementary downhole technologies will play an increasingly critical role in unlocking the full potential of hydrocarbon reservoirs and maximizing asset value in the oil and gas industry.