A Comprehensive Guide to Well Logging

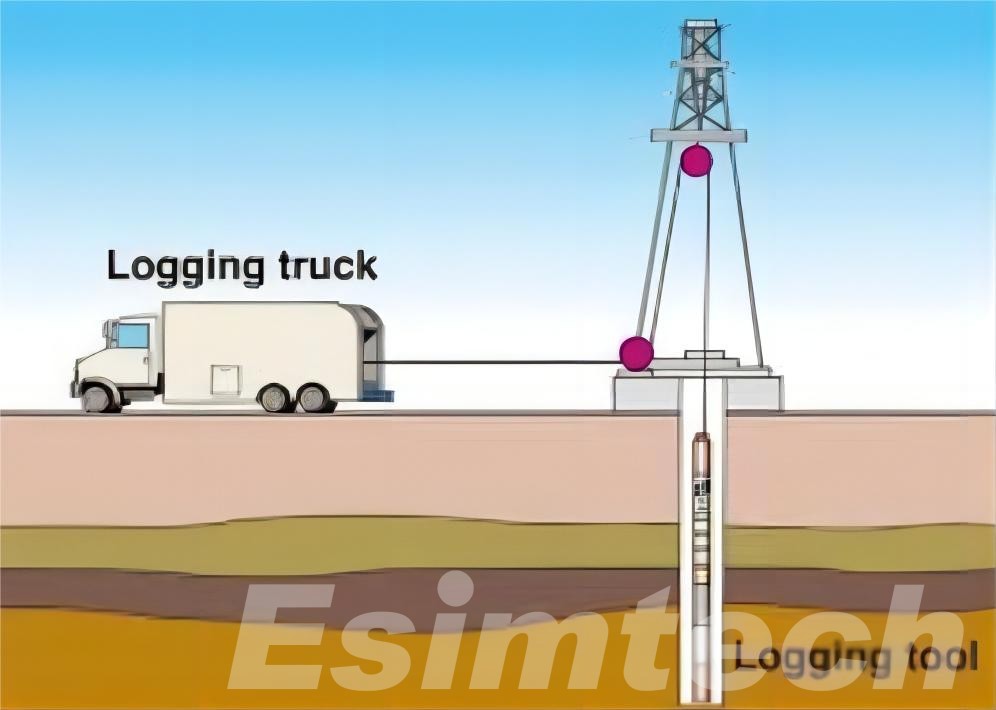

Well logging in the context of oil and gas refers to the process of obtaining information about the subsurface properties of a well. This is typically done by lowering instruments, known as logging tools, into the wellbore to measure various parameters. Well logging helps gather data on geological formations, fluid content, and other characteristics, aiding in the assessment of reservoir potential and the optimization of oil and gas extraction. The collected data is crucial for making informed decisions about well drilling, production strategies, and reservoir management in the oil and gas industry.

Importance of Well Logging in the Oil and Gas Exploration

Well logging plays a crucial role in the oil and gas exploration process. It involves the measurement and recording of various parameters and characteristics of rock formations and fluids within a borehole. Here are some key reasons why well logging is important in the oil and gas industry:

- Formation Evaluation: Well logging helps in assessing the characteristics of subsurface formations, such as porosity, permeability, lithology, and fluid content. This information is vital for understanding the potential productivity of a reservoir and making informed decisions about drilling and production strategies.

- Reservoir Management: By providing detailed information about the properties of reservoir rocks and fluids, well logging aids in reservoir management. Engineers and geoscientists can optimize production strategies, enhance recovery methods, and extend the life of oil and gas fields.

- Drilling Optimization: Well logs help in real-time monitoring of drilling operations. Data from well logging tools can be used to make decisions about adjusting drilling parameters, selecting appropriate drilling fluids, and avoiding potential drilling hazards.

- Identification of Hydrocarbons: Well logging is essential for identifying the presence of hydrocarbons in subsurface formations. Different logging tools can detect variations in rock and fluid properties associated with the presence of oil or gas, helping in the exploration process.

Safety and Environmental Considerations: The utilization of well logging yields vital insights into the geomechanical properties of rocks, facilitating the evaluation of wellbore stability. This data is pivotal in ensuring the safety of drilling operations and mitigating environmental concerns, particularly the risk of well blowouts. - Integration of Data: Well logging data is seamlessly integrated with other subsurface information, such as seismic data, to construct comprehensive models of the subsurface environment. This integrated approach enhances the comprehension of subsurface structures and elevates the precision of reservoir characterization.

- Support for Decision-Making: The information derived from well logging forms the foundation for decision-making throughout the exploration and production lifecycle. This encompasses decisions related to well completion, stimulation techniques, and abandonment strategies.

- Economic Assessment: Well logging plays a key role in evaluating the economic feasibility of oil and gas projects. The precise characterization of reservoirs allows for more accurate estimates of reserves, contributing to more dependable economic evaluations.

In summary, well logging is a critical tool in the oil and gas industry, providing essential information for reservoir characterization, drilling optimization, and overall decision-making processes. It contributes significantly to the efficient and sustainable development of oil and gas resources.

Types of Well Logging

1. Open-Hole Logging

Open-hole logging refers to the process of collecting data from a wellbore that has not yet been cased or lined. In this method, measurements are taken directly from the exposed rock formations, providing valuable information about the subsurface geology. The open-hole logging process is typically conducted after drilling but before casing to evaluate the potential reservoir.

Common Tools Used in Open-Hole Logging:

a. Gamma Ray Logging: Gamma ray tools are commonly employed in open-hole logging to measure natural gamma radiation emitted by the surrounding formations. This helps in identifying lithology and determining the presence of certain minerals.

b. Sonic Logging: Sonic tools emit sound waves into the formations and measure the travel time of the waves. This data assists in determining porosity and rock mechanics, providing insights into the formation's fluid content.

c. Density Logging: Density logging tools measure the bulk density of the formations. This information is crucial for calculating porosity and identifying changes in lithology.

2. Cased-Hole Logging

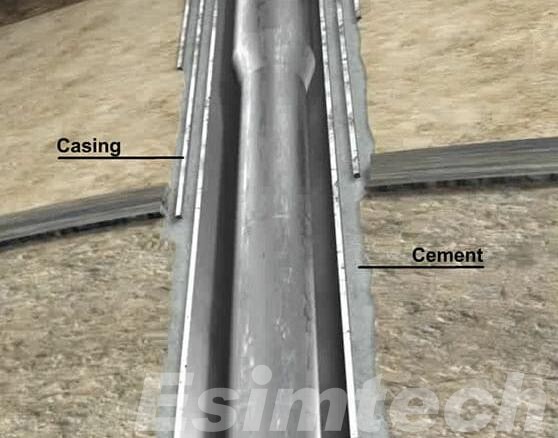

Cased-hole logging involves collecting data from a wellbore that has already been cased or lined with steel tubing. This is typically done after the well has been completed and production has started. Cased-hole logging is essential for monitoring the well's integrity, evaluating production zones, and assessing the effectiveness of completion techniques.

Common Tools Used in Cased-Hole Logging:

a. Cement Bond Logging: Cement bond logs are used to assess the integrity of the cement bond between the casing and the formation. This helps in identifying any voids or channels that may impact well integrity.

b. Noise Logging: Noise logging tools detect and analyze acoustic signals within the wellbore. This is valuable for identifying fluid movement and potential issues such as leaks or production problems.

c. Gamma Ray Spectroscopy: Gamma ray spectroscopy tools in cased-hole logging help identify the elemental composition of the formations behind the casing. This information aids in understanding the composition of produced fluids and evaluating reservoir changes.

3. Production Logging

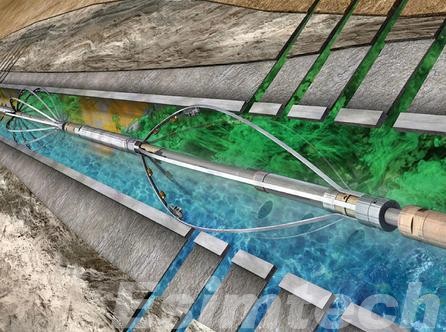

Production logging is focused on gathering data from the wellbore during the production phase. It provides insights into the flow behavior of fluids within the well, helping operators optimize production, identify production issues, and enhance reservoir management.

Applications in the Oil and Gas Industry:

a. Fluid Flow Profiling: Production logging tools measure the flow rates of individual phases (oil, water, and gas) within the wellbore. This information is crucial for optimizing well production and identifying areas of unwanted water or gas production.

b. Downhole Pressure and Temperature Measurement: Production logging tools can measure downhole pressure and temperature, aiding in understanding reservoir conditions and optimizing artificial lift systems.

c. Identifying Production Issues: Production logging is instrumental in detecting problems such as fluid coning, water or gas breakthrough, and wellbore damage. Timely identification of these issues allows for corrective actions to maintain or enhance production efficiency.

Well Logging Tools and Techniques

Well logging, also known as borehole logging, is the practice of recording physical properties of the Earth's formations encountered by a borehole. This information is used to evaluate the potential of a well for production of oil, gas, or water, as well as to characterize the geology of the area.

There are many different types of well logging tools and techniques, each of which provides information about a different aspect of the formation. Some of the most common types of logs include:

- Electrical logs: These logs measure the electrical conductivity of the formation. They can be used to identify porous and permeable zones, as well as to calculate water saturation.

- Nuclear logs: These logs measure the natural radioactivity of the formation. They can be used to identify formations that contain uranium, thorium, or potassium.

- Acoustic logs: These logs measure the speed of sound waves through the formation. They can be used to identify fractures, porosity, and lithology.

- Formation evaluation logs: These logs combine data from multiple logging tools to provide a more complete picture of the formation.

The specific type of well logging tool that is used will depend on the application. For example, in oil and gas exploration, electrical logs are often used to identify potential reservoir zones. In environmental monitoring, nuclear logs may be used to identify the presence of contaminated groundwater.

Well logging data is typically recorded on a downhole logging tool and then transmitted to the surface via a cable. The data is then processed and interpreted by a well logging specialist. The interpretation of well logging data can be complex, and it requires a good understanding of the underlying geology and physics.

Well logging is a valuable tool for understanding the Earth's subsurface. It can be used to make informed decisions about a variety of applications, such as oil and gas exploration, mineral exploration, environmental monitoring, and geotechnical engineering.

Technological Advances in Well Logging:Simulator

Technological advancements in well logging have ushered in a new era marked by the integration of sophisticated simulators, reshaping the landscape of subsurface exploration in the oil and gas industry. Simulators, in this context, have become instrumental in revolutionizing the acquisition and interpretation of subsurface data. These cutting-edge tools harness the power of virtual environments, offering a simulated representation of real-world well logging scenarios. This innovation empowers geoscientists and engineers by providing a dynamic platform to replicate and analyze diverse conditions within the wellbore and geological formations.

The key strength of simulators lies in their ability to simulate a multitude of logging scenarios, allowing professionals to explore and understand how different parameters interact in complex subsurface environments. Moreover, simulators serve as an invaluable tool for training and skill development in the realm of well logging. Professionals can engage in realistic, hands-on simulations that replicate the challenges and intricacies of well logging processes. This immersive learning experience not only accelerates the learning curve for new practitioners but also allows seasoned experts to refine and enhance their skills in a risk-free virtual environment.

The integration of simulators in well logging represents a paradigm shift, where technology meets the complex demands of subsurface exploration. As technology continues to evolve, simulators are poised to play an increasingly pivotal role in advancing the precision, safety, and efficiency of well logging processes, shaping the future of subsurface exploration in the oil and gas industry.