What are the Top 5 Cased Hole Logging Tools

In the oil and gas industry, efficient management of a wellbore’s productivity and maintaining the well’s structural integrity over time are essential for efficient operations. One of the important methods of monitoring the well condition post casing setting and cementing is cased hole logging. This article delves into the definition of cased hole logging, describes the five most important tools used in the industry, and discusses major subsurface cased hole logging applications.

What is Cased Hole Logging in oil and gas?

Cased hole logging is one of the most vital processes in the diagnostics of oil and gas industry to examine the performance of the wells after installation and cementing the casing. Cased hole logging is different from open hole logging in the sense that the former is done after the casing is set while the latter is done before the casing has been set. Cased hole logging is critical in fetching data all the way through the life of the well including during the interventions and even after abandonment.

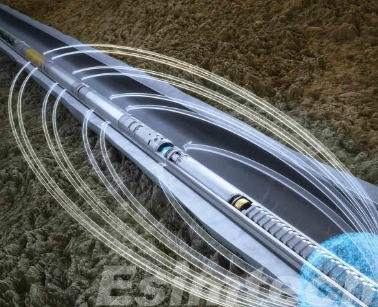

In measuring various parameters of fluid flow, pressure, temperature, and cement integrity, It is necessary to lower special tools to the wellbore using slickline, coiled tubing, or wireline. In such cases, coiled tubing is done on the lower side to enhance fluid flow. These parameters assist the engineers in getting the data they need in the diagnostics such as discerning leaks, checking the integrity of the casing, and monitoring the production zones.

In matured fields, production is of utmost value and thus, cased hole logging is vital as such fields need sophisticated technologies for optimization and better maintenance. Cased hole logging also assist engineers and operators regarding well workovers, perforation, P&A, and zonal isolation related decisions.

Cased hole logging Provides the operators with real time high precision data which helps in making better decisions. Such data also assist in making during planning that enhances the efficacy of the well and save funds. It makes cased hole logging as an integral part of well production and surveillance engineering.

Top 5 Cased Hole Logging Tools Explained

Cased hole logging tools are crucial for obtaining key data for wells that have been cased and cemented. These tools assist engineers in diagnosing and monitoring well performance, undergoing proactive problem detection, and making well-informed decisions. Below are the top 5 cased hole logging tools used in the oil and gas industry:

- Gamma Ray Tool: The Gamma Ray (GR) tool is one of the more fundamental cased hole logging tools, but it is extremely important. It measures natural gamma radiation from rock formations behind the casing. This information is used for depth correlation, aiding in matching cased hole logs with previously recorded open hole logs. It also assists in the identification of shale and non-shale zones, particularly during perforation planning.

- Multifinger Caliper Tool: The Multifinger Caliper Tool‘s mechanical fingers enable it to examine and measure to monitor the changing diameter of the casing and uncover internal well issues like corrosion and scale build-up. Such preliminary data enables estimation of wellbore health and supports maintenance decision-making.

- Production Logging Tool (PLT): PLT systems are designed to determine the movement of fluids within the wellbore and analyze the complex flow of fluids through the wellbore. With wellbore flow sensors such as flowmeters, temperature, pressure sensors, and phase detectors, PLTs monitor and analyze fluid types and their velocities in real time. This makes it easy to locate production zones and resolve issues like water or gas coning.

- Noise and Temperature Logging Tools: Temperature and Noise Logging Tools focus on wellbore temperature and acoustic monitoring to reveal fluid leakage in the well through leaking, channeling, or behind-casing flow. Temperature monitors track wellbore fluid movement, and gas or fluid Noise logs capture the acoustic signature of escaping gas or fluid. They are particularly beneficial in injector wells and in the assessment of well integrity.

Reservoir performance can be sustained, and enhanced reservoir production efficiency and long-term well dependability can be achieved through the utilization of the described tools.

Applications of Cased Hole Logging

Cased hole logging serves a strategic and fundamental function during the lifecycle of a well. It provides information that aids in production optimization, well integrity, and reservoir management. After the casing is set and cemented, these tools are the primary means of evaluating the downhole environment without needing to remove the completion hardware.

The most notable functions of cased hole logging in oil and gas operations are the following:

- Evaluation of the Well Integrity: Cased hole logging is particularly useful in evaluating the well’s architectural fitness. Cement Bond Logs (CBLs) and Multifinger Calipers are some of the tools that are used to assess cement integrity, casing corrosion, and structural casing damage. This facilitates safe operations of the well while ensuring compliance with environmental regulations.

- Profiling of the Well Production: The contribution of different zones to overall production can be measured with Production Logging Tools (PLTs). Measurement of flow rates, temperature, and the type of fluid enables operators to identify zones that are efficiently performing, pinpoint water or gas breakthroughs, and proactively act to maximize production.

- Detection of a Leak: Leak, crossflow, and channeling in the casing are identifiable by means of noise and temperature logging. If these problems are not identified and resolved in a timely manner, they risk compromising production effectiveness and environmental safety.

- Reservoir Monitoring: Long-term monitoring of the reservoir Tracking changes in pressure, temperature, and saturation, oil fields and wells fitted with cased holes can be monitored for quite a long time. This data is essential for monitoring the movement of fluids in the reservoir for enhanced oil recovery (EOR) operations.

- Plug and Abandonment ( P&A ): Logging tools are used to check the condition of the casing and the bond of the cement. This ensures that the abandonment process for the well is regulatory compliant.

Incorporating these practices into routine monitoring allows for increased well life and reduced downtime, adding greater value to the oil and gas assets.

Final Thought

Cased hole logging measures and analyzes oil and gas fields to guarantee well integrity and production optimization. These technologies are critical in asset optimization whether it is on cement bond strength evaluation with cement bond logs or on flow anomaly detection with PLTs and temperature tools.

The five most important cased hole logging tools enable maximizing operational efficiency alongside health, safety, and environmental compliance. The future of cased hole logging is even more precise as digital telemetry, real-time analytics, and AI diagnostics are on the rise.