What is the Portable Drilling Well Control Simulator

Drilling operations contain inherent risks that necessitate extensive training and preparation. The development of innovative training tools is critical for ensuring staff safety and optimizing operational efficiency. The portable drilling well control simulator is one such innovation, designed to deliver realistic, hands-on training experiences in a compact and portable form.

How the Portable Drilling Well Control Simulator Simulating Realistic Well Control Scenarios

Well control is critical in the high-stakes area of drilling operations. Drillers and well control teams must get realistic and effective training to ensure the safety of workers and equipment. Simulators that can accurately recreate well-control scenarios come in handy here.

Trainees gain essential hands-on experience in addressing critical circumstances by simulating realistic well control scenarios. These simulators replicate the intricacies and challenges experienced during drilling operations, allowing learners to develop the essential skills, knowledge, and confidence to properly handle emergencies. Let's explore how simulators achieve this realistic simulation.

Dynamic Physics and Fluid Modeling

To simulate the behavior of fluids encountered during drilling, well control simulators use complex physics and fluid modeling methods. They represent the dynamic interaction of drilling mud, formation pressures, and wellbore conditions. Simulators can precisely simulate the pressure fluctuations, influxes, and outflows that occur during well control incidents by accurately simulating the fluid dynamics.

Real-Time Monitoring and Feedback

Simulators provide real-time monitoring of critical parameters, such as wellbore pressure, flow rates, and choke settings in real-time. Trainees can monitor and analyze changing well conditions, allowing them to make informed judgments based on simulated data. Trainees can examine the success of their efforts and alter their reactions in real time thanks to instant feedback.

Emergency Scenarios

Simulators provide a variety of emergency scenarios to test trainers' abilities. Well kicks, blowouts, loss of circulation, and other severe conditions necessitate prompt action. By simulating these emergencies, trainees can practice well control techniques such as shutting down the well, managing pressure, and executing situation-specific well control procedure.

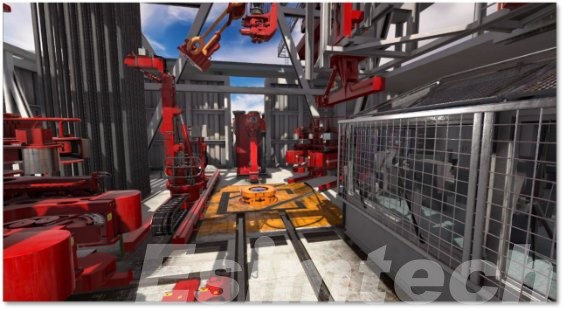

Equipment and Control Panel Replication

To create a realistic teaching environment, simulators imitate drilling rig equipment and control panels. Trainees can interact with virtual control panels and operate drilling equipment such as BOPs, mud pumps, and chokes. This hands-on training allows trainees to get more familiar with the equipment and improves their ability to respond quickly and efficiently during well control issues.

Communication and Decision-Making

Well control simulators simulate a drilling team's communication network and dynamics. By coordinating actions with other team members, sharing information, and managing resources, trainees can learn good communication and decision-making. This collaborative environment encourages teamwork and trains trainees for the coordination required in real-world well control circumstances.

Variable Training Difficulty

Simulators allow you to tailor the difficulty level of training scenarios to the experience and skill levels of your students. Novice drillers can begin with basic scenarios and proceed to more complicated and challenging ones as their proficiency grows. This adaptive training method ensures that students are appropriately prepared for a wide range of well control scenarios that they may face in the field.

What are the Key Features and Benefits of the Portable Drilling Well Control Simulator

Hands-on Training

The simulator offers a hands-on approach to learning well control techniques. Trainees can actively interact with the simulated equipment, control panels, and well control processes, gaining hands-on experience in dealing with crises and making vital decisions. This interactive training method improves skill development and increases confidence.

Portability and Flexibility

The portable nature of the simulator allows it to be easily transported and set up in various locations, including training centers, on-site training facilities, or even offshore platforms. This flexibility enables convenient access to well control training, eliminating the need for trainees to travel long distances for training purposes.

Risk-free Environment

The simulator provides a risk-free training environment in which learners can practice and improve their well control skills without endangering crew safety or causing damage to equipment. It enables trainees to experiment with various strategies and techniques, allowing them to learn from their failures and build successful responses to well-controlled challenges.

Performance Evaluation and Feedback

The simulator tracks trainees' progress and delivers instant feedback on their actions and decisions. This evaluation approach enables trainees to evaluate their performance, find areas for improvement, and fine-tune their well management techniques. Continuous feedback and performance indicators enable focused training interventions and tracking of development over time.

Cost-Effective Training

Investing in a portable drilling well control simulator can help you save money on training in the long term. Companies can save money on travel, lodging, and equipment rental by providing well control training on-site or at nearby training institutes. The reusability and durability of the simulator contribute to long-term cost savings.

Enhancing Safety Awareness

By simulating well control scenarios, the simulator enhances safety awareness among trainees. It allows them to experience the potential risks and consequences associated with well control incidents firsthand, instilling a deep understanding of the importance of safety protocols and the need for proactive risk management.

Team Collaboration and Communication

The simulator promotes effective communication and teamwork among drillers and well control teams. In a virtual setting, trainees can practice coordinating actions, sharing information, and making group choices. This encourages teamwork, improves coordination abilities, and increases the overall effectiveness of well control operations.

Scenario Customization

The simulator allows you to tailor training scenarios to fit specific learning objectives. It gives them firsthand experience with the potential dangers and consequences of well-controlled catastrophes, instilling a firm understanding of the need of safety precautions and the need for proactive risk management.

Continuous Training and Skill Development

The simulator facilitates continuous training and skill development. The simulator can be used to offer more complicated scenarios and difficulties as students advance and grasp basic well control procedures. This method of incremental training assures continual skill growth and prepares learners for a variety of real-world well control conditions.

Summary

The portable drilling well control simulator is a big step forward dedicated to safety and efficiency in the petroleum industry. It is an important tool in training the next generation of qualified drilling experts as the industry continues to prioritize safety and enhance operational efficiency.