6 Trends and Innovations in Drilling and Well Control Simulators

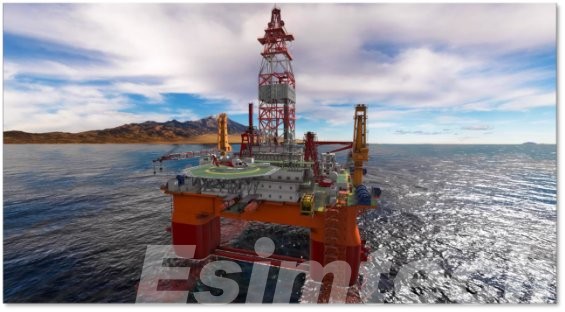

Drilling and well control simulators have become an essential tool in the oil and gas industry, providing personnel with the necessary training to respond to well control incidents. In recent years, there have been significant advancements in the technology used in these simulators, resulting in more realistic and effective training experiences. In this article, we’ll explore the latest trends and innovations in drilling well control simulators.

Advanced software and graphics Trend in Drilling and Well Control Simulators

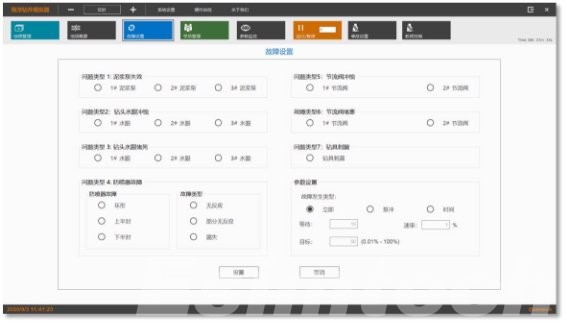

One of the key trends in drilling well control simulators is the use of advanced software and graphics. These tools are used to create more realistic and immersive training experiences. High-fidelity graphics and 3D models of well sites, drilling equipment, and downhole scenarios are now commonplace in drilling well control simulators. The use of mathematical models that simulate drilling parameters, such as flow rate, pressure, and temperature, is also becoming more prevalent. By incorporating advanced software and graphics, drilling well control simulators are becoming more effective at preparing personnel for real-life well control incidents.

Artificial Intelligence and Machine Learning Trend in Drilling and Well Control Simulators

AI and ML are being incorporated into drilling well control simulators to create more realistic and dynamic training scenarios. AI algorithms can simulate real-time events, such as equipment failures and weather changes, to train personnel on how to respond to unexpected situations. This can provide trainees with a more realistic and challenging experience that improves their decision-making and problem-solving skills. In addition to simulating well control scenarios, AI and ML are also being used to analyze data from real-life incidents to identify patterns and trends. This data analysis can be used to improve well control training by identifying areas where personnel may need additional training or support.

Virtual and Augmented Reality Trend in Drilling and Well Control Simulators

Virtual and augmented reality technology is being used to create more realistic simulations that allow trainees to physically interact with the training environment. This can improve training effectiveness by providing a more immersive experience that closely mimics the real-world environment. For example, trainees can use virtual reality headsets to simulate different well control scenarios, including the use of equipment and tools in a simulated environment. Augmented reality is also being used to enhance training by overlaying real-time data on top of the simulation. This can provide trainees with additional information about the drilling environment and help them make better decisions during well control incidents.

Cloud-based Training Trend in Drilling and Well Control Simulators

Cloud-based training is becoming more popular in the oil and gas industry, and drilling well control simulators are no exception. Cloud-based training allows trainees to access training modules from anywhere and at any time, which can improve training efficiency and reduce costs. This type of training is especially useful for remote drilling sites where it may be difficult or costly to bring in a physical simulator. In addition to providing flexibility and convenience, cloud-based training is also more scalable than physical simulators, allowing organizations to train larger numbers of personnel more efficiently.

Integration with Real-time Data Trend in Drilling and Well Control Simulators

Drilling well control simulators are being integrated with real-time data from drilling operations to create more dynamic training scenarios. This allows trainees to practice responding to real-time events and can improve their ability to make quick decisions during well control incidents. For example, real-time data on the wellbore pressure, mud weight, and other parameters can be used to create simulations that closely mimic actual drilling conditions. In addition to enhancing training, the integration of real-time data can also improve the safety of drilling operations by providing personnel with up-to-date information about drilling conditions.

Gamification Trend in Drilling and Well Control Simulators

Gamification is being used to make drilling well control simulators more engaging and fun for trainees. This involves the use of game-like elements, such as points, levels, and rewards, to motivate trainees and encourage them to complete training modules. This can improve training effectiveness by making the training experience more enjoyable and interactive.Simulation-based training has become an increasingly popular approach to prepare personnel for well control incidents. Drilling well control simulators offer a safe and controlled environment where trainees can learn and practice how to respond to different well control scenarios without risking the safety of personnel or damaging equipment. With the latest trends and innovations, drilling well control simulators are becoming more realistic, effective, and engaging, providing personnel with the necessary skills and knowledge to respond to well control incidents.

In summary, the latest trends and innovations in drilling well control simulators include the use of advanced software and graphics, AI and ML, virtual and augmented reality, cloud-based training, integration with real-time data, and gamification. These trends and innovations are improving the effectiveness of well control training by creating more realistic and dynamic training experiences that closely mimic real-world scenarios. By preparing personnel to respond to well control incidents, drilling well control simulators are helping to ensure the safety of drilling operations and the environment.