How Jack-Up Rigs Are Engineered for Harsh Environments

Offshore drilling often happens in some of the toughest waters on the planet—places where giant waves crash, ice forms, and the weather changes in the blink of an eye. To work safely and get the job done right, crew need special drilling units designed just for the job. One of the most popular choices is the jackup rig, a hero in shallow-water oil and gas operations. But what special features help a jackup platform conquer these extreme challenges? Let’s take a closer look.

What is a Jackup Rig?

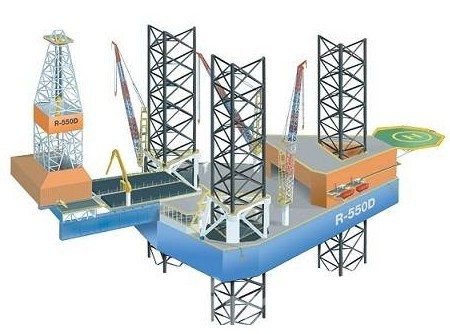

Jackup rigs represent a distinctive category of mobile offshore drilling units extensively deployed within the oil and gas sector, targeted chiefly at shallow-water exploration and exploitation. Differing fundamentally from floating rigs—which depend either upon moored anchors or sophisticated azimuth thruster assemblies—jackup units employ a triad of elongated tubular steel legs. These legs are gradually lowered until firm seabed contact is achieved. Thereafter, the adjacent hull is raised through a series of rack-and-pinion mechanisms, positioning the drill floor well clear of the surface and yielding a stable drilling platform.

Elevating the hull above the wave envelope is a critical safety and operational design consideration; the effect is to situate the working deck and the associated drilling control apparatus above Atlantic and equatorial swell, thereby dampening the violent oscillatory forces of open water. As a consequence, operational efficiency is enhanced and the potential for mechanical hazards is diminish. Standard specifications allow conventional jackup rigs to undertake drilling and completion work at water depths to a maximum of 400 feet; designs labeled “premium,” however, are achieving operational envelopes that extend well beyond the conventional metrics.

The triad of stability, economic viability, and rapid mobilization capability renders jackup drilling units the preferred technological solution for offshore campaigns in selective but economically critical corridors—namely, the hydrocarbon provinces of the North Sea, the Arabian Peninsula, and the island and river delta provinces of Southeast Asia.

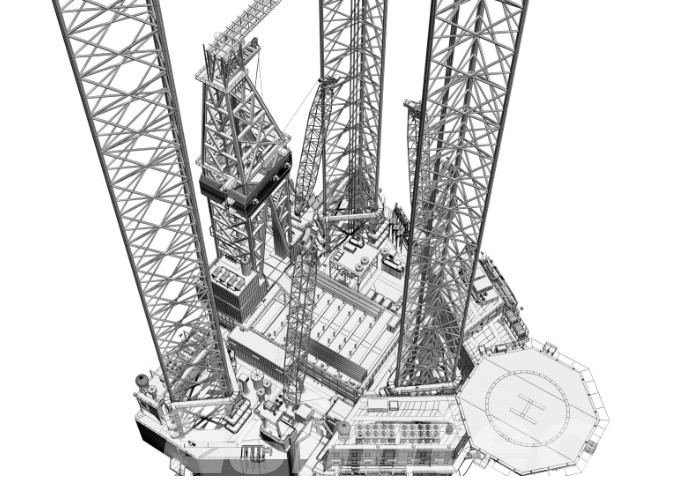

Key Components of a Jack-Up Rig

A jackup rig is more than a floating ship with legs—it's a well-engineered offshore system built to accommodate advanced drilling operations while maintaining safety and stability in unfavorable situations. Each jack up platform is made up of a variety of separate items, functionally integrated to enable efficient functioning.

- Hull: Hull is the main body of the rig that contains the living space, power systems, storage areas, and the majority of the drilling gear. During mobilization of the rig to a new location, the hull is used as the floating base before the lowering of the legs.

- Legs: Three or four immense steel legs, typically lattice or columnar, outfit jackup rigs. The legs are jacked down onto the seafloor and pin the rig in place, lifting the hull above wave level to stabilize the rig.

- Jacking System: A hydraulic or electric jacking system is utilized to lift and lower the hull on the legs. This is essential in giving the rig the proper height above sea level to be out of wave action and provide a safe working deck.

- Drilling Package: The focal point of all drilling jack up rigs is the drilling package, which comprises the derrick, drill floor, mud systems, and blowout preventers. All these help the rig safely drill into subsea reservoirs.

- Support Systems: Other systems like ballast control, power generation, safety equipment, and emergency evacuation facilities provide round-the-clock and safe offshore operations.

All these factors combined make jackup rigs efficient offshore drilling vessels in extreme sea conditions.

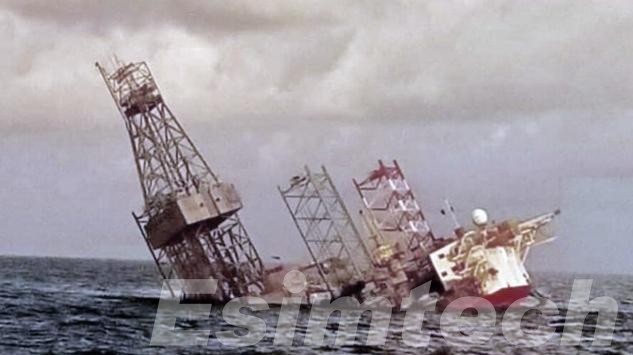

Engineering Challenges of Oil Rig in Harsh Environments

Operating a jack-up rig in harsh offshore environments is a whole different ball game compared to working in calm, shallow waters. Safety, stability, and efficiency hinge on managing a bunch of factors at the same time. Here are four of the biggest challenges engineers face:

1. Energy Storm and Ocean Forces

Jack-up rigs are not parked in a marina. They’re out in the open, where tough ocean conditions are the norm. Winds whip, waves tower, and storms can roll in without warning. In the North Sea, for example, a rogue wave can reach over 20 meters, slamming into the rig like a freight train. To cope, designers build a hull that flexes, a leg framework that distributes the blow across the keel, and a storm strategy that raises the hull several meters above the wave train to dodge the worst of the hit.

2. Seabed Soil Problems

Think of the rig's legs as the anchors on a gigantic tripod. They need to dig in, but the seabed can be like a box of chocolates: hard clay, uneven rock, or quicksand, truthfully. If a leg hits the soft stuff, it can sink too far or slip, ruining stability. Engineers tackle this by beefing up the spud cans and gathering seabed soil data weeks in advance. By knowing the soil's secrets, the rig can land securely, like a robot in the obstacle course, and keep steady in the swell.

3. Low Temperatures and Ice Formation

Freezing weather in the Arctic and sub-Arctic puts ice on everything—decks, engines, and even the legs that support the rig. The added ice weight can trigger alarms, the slick surfaces are ready to throw someone, and the machinery might crack. To counter this, crews wrap rigs in winter armor: steam tubes to melt ice, heated cabins that feel like home, and chemicals that stop ice from even forming. Thanks to these systems, engines keep humming, and the crew can focus on the job instead of fighting each flake that falls.

4. Corrosion and Material Fatigue

Day in, day out, the ocean sprays salt across the platform, launching a never-ending saltwater assault. For a jack-up platform, this means steel rusts faster, and the platform flexes like a spring in every wave and wind gust. To delay this slow cooker of damage, the team picks better steel blends, sprays on protective coatings, and schedules inspections that rival military precision. Cameras and sensors quietly log every crack and flex, emailing the team if anything looks off. Thanks to these steps, rigs last, making every drill campaign safer and the next crew a whole lot happier.

How Jack Up Platforms Are Engineered for Harsh Environments

To brave the extreme offshore environment, today’s jack-up drilling platforms rely on clever engineering solutions that tackle the toughest hurdles of deepwater well work, raging storms, and shifting sea floors.

1. Reinforced Legs and Hull Framework: The legs are the centrepiece of every jack-up rig. They must absorb constant bending from swells and swirls. New platforms use extra-tough steel with thickened walls designed to resist kinking. Some federations sport lattice-style legs that slice through water while delivering dependable strength. Around the legs, the hull receives upgraded cage bracing and watertight cells to boost flotation and keep seawater at bay.

2. Smart Ground Contact: An uneven or soft seabed poses the threat of legs gradually tilting or the ground simply sucking them in. Designers fight back by using oversized spudcans that spread the load over a wider area. Engineers then run make-believe load trials that press the legs to the maximum force, well in advance of the first well bit touching the rock. Some builders add ‘suction follies’ that pull a mild vacuum, sealing the spudcan to the seabed and doubling the footing grip.

3. Weather Shielding: In areas where storms can ramp to hurricane speed, offshore jack-ups add adjustable elevation kits that make raising the entire deck a dial-up task, lifting the legs and hull well clear of incoming swells. Smart positioning gadgets keep the rig oriented even in sideways currents. If things worsen, instant disconnect couplings detach the mudline pressure connectors from the well, keeping the rig safe while the subsea shutdown system takes over.

4. Corrosion and Fatigue Protection: Salt, constant wind, and loading cycles can wear rig structures faster than you'd expect. To fight corrosion, crews install cathodic protection systems that use low-level electrical currents to stop rust before it starts. Key joints get a double defence of epoxy and zinc-rich coatings. Between paint and ports, ultrasonic tests find invisible cracks so small that the human eye can’t spot them; catching them early prevents major repairs later.

- Cold-Weather Modifications: When a rig heads to Arctic waters, heated decks help keep ice from piling up. They also switch to low-temperature steel alloys, which bend instead of break in the deep cold. Ice deflectors route drifting sheets harmlessly away, so floating ice can’t scrape or crush legs. By layering these technologies, jack-ups hold the line both in temperatures that bite and in seas that bite back, delivering dependable service where the forecast looks the worst.

Conclusion

The engineering of a jackup rig goes far beyond basic drilling requirements—it is cutting-edge synergism of engineering and safety technology. With reinforced hulls, robust legs, strong jacking systems, and weather-proof elements, a drilling jack up rig can withstand rough offshore conditions and maintain stability and effectiveness.

As offshore oil and gas exploration ventures further into more aggressive conditions, the jack up platform will remain as vital in the future. Future technologies like digital monitoring and cleaner power systems will provide even safer and more environmentally responsible operations in coming decades.