Dual Gradient Drilling (DGD) for Enhancing Well Control

In modern deepwater and offshore drilling operations, managing wellbore pressure is one of the most critical challenges. Traditional single-gradient drilling systems often face limitations when encountering narrow pore pressure and fracture gradients, especially in ultra-deepwater wells. To overcome this challenge, Dual Gradient Drilling (DGD) is emerging as a revolutionary technology that significantly enhances well control and safety, while reducing overall drilling costs.

Understanding Dual Gradient Drilling

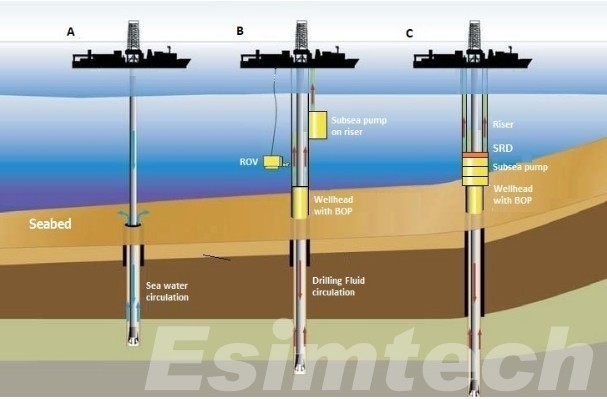

Dual Gradient Drilling (DGD) is a method which separates the annular from the drill pipe's gradient of pressure making use of two different profiles of fluid density that are one inside the drill string, and one inside the annular region. This is usually accomplished by decreasing the hydrostatic pressure inside the annulus by using subsea pumps or a dilution fluid or any other equipment for managing pressure that allows for more precise and dynamic control over bottom hole pressure (BHP).

Contrary to conventional drilling, where all mud columns creates only a single upward pressure from its surface to the reservoir DGD technology allows the pressure on the surface to decrease while keeping the desired pressure at lowest point of the drill.

Here's a chart that outlines the benefits of dual-gradient drilling over traditional drilling

| Aspect | Conventional Drilling | Dual Gradient Drilling |

| Pressure Management | One gradient restricts flexibility in small pressure windows. | Two gradients permit exact control of the pressure at the bottom of the hole. |

| Kick Detection | Slower detection due to compressible fluid column | Early kick detection due to more rapid response to pressure |

| Formation Integrity | Greater risk of fracture formation or collapse | Risk reduction through a more balanced pressure balance |

| Drilling Margin | Constrained in pore-fracture windows with narrow pores | Margin expansion due to decoupled surface pressures and bottom-hole pressures |

| Non-Productive Time (NPT) | NPT is higher NPT is due to pressure-related problems (e.g. circulation problems, etc.) | Reduced NPT by proactive well control |

| Well Control Response | Reactive approach that is limited in flexibility | Real-time pressure adjustments enable proactive control |

| Access to Challenging Zones | Access to restricted areas in high-risk and ultra-deepwater formations | Allows drilling in previously unexplored or hazardous areas that are risky or untested. |

| Mud Weight Requirements | It requires more sediment throughout the column | Allows for the use of mud with a lighter weight while maintaining the wellbore's stability. |

| Casing and Liner Programs | Needs more casing strings due to pressure limitations | Possible reduction in string casings, reducing costs and complexity |

How Does Dual Gradient Drilling Improve Well Control

1. More Precise Pressure Management

One of the most fundamental methods Dual Gradient Drilling improves well control is through better pressure control. In traditional drilling, ensuring adequate pressure at the bottom of the hole often means the use of the use of a heavy drilling mud. This can cause fracturing of the formation or losing circulation. DGD permits the utilization of lighter fluids within the annulus while maintaining required pressure in the reservoir. The ability to adjust the pressure in different areas of the well greatly minimizes the chance of crossing fracture gradients, or even dropping below the pressure of the pore either of which could result in serious issues with control of the well.

2. Early Kick Detection and Faster Response

Kick detection, which detects the moment formation fluids enter the wellbore is an important element of maintaining control over the well. For Dual Gradient Drilling systems, the annular column of fluid is more brittle due to its reduced height or density, which makes pressure fluctuations even the smallest influxes evident. This enhanced sensitivity permits quicker kick detection than traditional systems. By detecting earlier the operators can begin shut-in procedures as well as other safety measures quicker, which reduces the possibility of a blastout.

3. Reducing the Risk of Formation Damage

When drilling through formations that have small pressure margins, there's the risk of creating damage through applying too much or not enough pressure. With DGD the ability to regulate pressure in a precise manner reduces the pressure that's put to the formation. This decreases the risk of collapse in the formation or the loss of mud, both which could compromise the integrity of wells and cause grave well control issues.

4. Greater Flexibility in Challenging Environments

Dual Gradient Drilling increases well control, making it possible to drill in areas that were previously thought to be too complicated or risky. In ultra-deepwater, high-pressure, HPHT (HPHT) conditions the use of narrow drilling margins is prevalent. Dual gradient systems permit operators to alter pressure at a real-time rate in response to changes in conditions within the downhole. This allows for an even pressure throughout the bottom of the hole when the well is getting deeper, which results in more secure and controlled drilling.

Key Technologies and Methods Used in Dual Gradient Drilling

| Technology/Method | Description | Purpose in Dual Gradient Drilling |

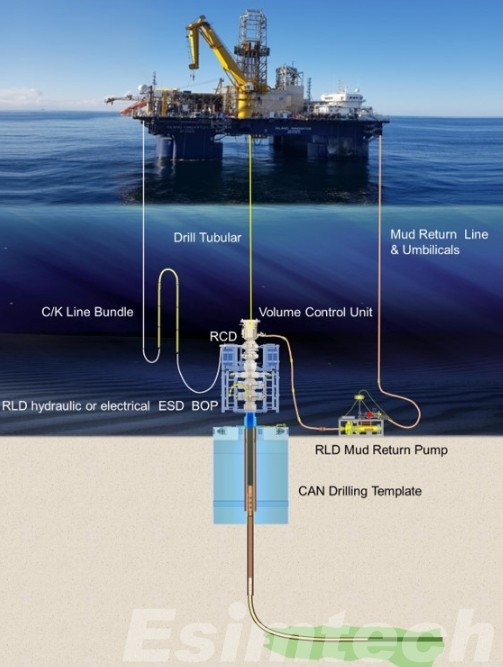

| Mud Lift Pump System (MLPS) | Subsea pump lifts mud off the bottom of the sea to the surface and reduce the pressure in an annular. | Keeps pressure at the bottom while reducing head hydrostatic on the surface. |

| Dilution-Based System | Fluids that are lighter (e.g. seawater) are injected to reduce the density of the annulus. | Controls annular pressure gradients without the use of heavy mud. |

| Controlled Mud Level (CML) | A separate chamber is responsible for managing the level of fluid to control the annular pressure. | It provides precise pressure control via the adjustment of height of the fluid. |

| Riserless Mud Return System (RMRS) | Retrieves mud from the surface without using a traditional riser, by using Subsea return lines. | In top-hole sections, it is used to control pressure more effectively. |

| Subsea Rotating Control Device (RCD) | The seabed is sunk to close the annulus and permit the control of pressure. | Allows closed loop drilling and pressure-containment at depth. |

| High-Pressure Mud Injection System | Injects fluid into certain zones to help stabilize pressure. | It is used to stop sudden kicks or pressures in formation. |

| Downhole Pressure Sensors | Measure real-time pressure data at various depths. | Critically evaluate the effectiveness of keeping pressure windows at the target. |

How Simulation Technology is Used in Dual Gradient Drilling for Improving Well Control

Given the complexity of managing two pressure gradients within a single well system, oil and gas simulation tools provide the needed insight and predictive power to to make sure that operations are secure and efficient, particularly in high-risk and deepwater drilling environments.

Pre-Drill Planning and Scenario Modeling

Before drilling starts the use of simulation technology is employed to simulate the conditions of drilling. Engineers can simulate a variety of geochemical conditions, fluid behavior and operational parameters by using digital twin models as well as highly-fidelity hydraulic simulations. These simulations aid in determining optimal mud weights, pumps rate, as well as annular densities required to ensure the control of wells. Additionally, they allow teams to identify potential pressure imbalance scenarios or kick risk, as well as deepening the seat of the casing, thereby improving the design of the well and reducing time wasted.

Real-Time Monitoring and Predictive Analytics

When drilling Simulation systems work in conjunction with live data feeds from downhole sensors and surface machinery and subsea parts. Advanced simulation systems can analyse this data on a continual basis to forecast changes in the bottom-hole pressure and formation fluid behavior and the possibility of an inflow or loss. If a pressure anomaly is discovered the model of simulation can recommend the best strategy for responding based on modelled scenarios. This capability to predict is greatly improving the capability of an operator to keep good control in dynamic environments.

Training and Crew Readiness

Controlling wells for well control in Dual Gradient Drilling operations demands an expert level of knowledge and awareness of the situation. Simulation-based drilling training platforms offer teams real-world environments that allow them for a variety of Dual Gradient drilling procedures including kick detection and annular pressure management as well as subsea pumps control. The training simulators mimic the actual behavior of a dual-gradient device under different stress conditions, assisting teams develop the abilities and confidence to effectively and control the effects of incidents.

Design and Optimization of Dual Gradient Drilling Systems

Simulation can also assist in the design and engineering stage design and engineering of DGD infrastructure. Engineers employ the computational fluid dynamics (CFD) and hydraulic simulators to assess their performance on risers systems as well as subsea mud pump as well as rotating control devices and controlled mud chambers for level. By understanding how each part performs under conditions of flow and stress the equipment can be improved to ensure reliability and efficiency and ultimately, better outcomes for well control.

Supporting Innovation and Risk Assessment

In the course of Dual Gradient Drilling technologies continue to develop, emergency training simulation plays a crucial function in testing innovation and risk assessment. The latest DGD concepts, like automated pressure balancers, AI-assisted drill controls or mixed gradients, are able to be evaluated online prior to field deployment. This minimizes the risk that comes with trial-and-error scenarios in real-world environments and helps speed up the implementation of safer, more intelligent techniques for controlling wells.

Industry Applications of Dual Gradient Drilling Used for Enhancing Well Control

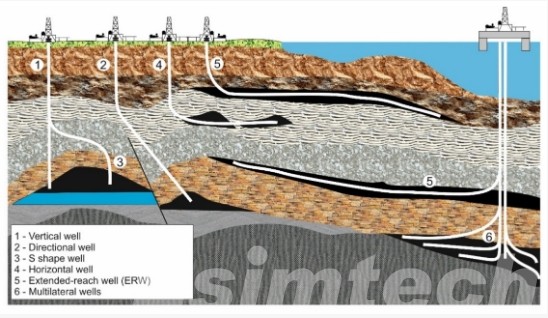

1. Ultra-Deepwater Drilling

Dual Gradient Drilling has proven especially beneficial in ultra-deepwater drilling conditions, in which long risers cause an excessive hydrostatic pressure. This can reduce the gap between the fracture and pore pressure. Through lowering annular pressure using dual gradient techniques, Dual Gradient Drilling lets you drill more safely into deep formations, lowers the chance of fractures in the formation, and offers better kick detection.

2. High-Pressure, High-Temperature (HPHT) Wells

For HPHT wells, the management of pressure is both challenging and critical. Dual Gradient Drilling allows for dynamic control of conditions downhole, which allows operators to control sudden fluctuations in temperature and pressure of the formation. The increased response time and stability of the pressure can prevent the risk of blowouts and kicks, thereby making the well more stable overall.

3. Extended Reach Drilling (ERD)

Extended Reach Drilling involves horizontal sections that stretch for a number of kilometers. The ability to maintain constant pressure in the bottom hole over the length of these distances is a challenge with traditional methods. Dual Gradient Drilling gives a constant pressure control throughout the bore, which reduces the chance of sticking in the wellbore, differential instability and loss of circulation.

4. Deepwater Development with Fewer Casing Strings

Deepwater drilling traditionally calls for multiple capillary strings in order to handle various pressure gradients. Dual Gradient Drilling provides greater control of pressure across various zones and reduces the need for casing. This is not just cost-effective but also streamlines the overall structure of wells while ensuring solid well control.

5. Drilling in Geologically Unstable Formations

In the case of fractured carbonates or unconsolidated sandy sands the stability of the wellbore is of paramount issue. Dual Gradient Drilling reduces the requirement for clay weights that could harm fragile formations. This more gentle pressure management ensures the wellbore's integrity and helps avoid complications like formation collapse or loss of fluid.

6. Exploratory Drilling in Unknown Pressure Regimes

Exploration wells typically involve uncertainty regarding formation pressure profiles. Dual Gradient Drilling provides real-time pressure adjustment that is particularly useful in the event that unexpected pressure zones are discovered. This enhances safety and lowers the chance of unexpected well control incidents in the initial reservoir assessment.

Challenges and Future Innovations in Dual Gradient Drilling for Enhancing Well Control

| Category | Challenges | Future Innovations |

| System Complexity | The integration of subsea pumps as well as RCDs and fluid systems increases mechanical complexity | Compact, modular Dual Gradient Drilling systems that offer an easy subsea deployment |

| Operational Costs | More upfront costs than conventional drilling | Hybrids that are cost-effective DGD solutions, as well as broader commercial accessibility |

| Real-Time Monitoring | Advanced downhole sensors are required and integration of surface data | AI-powered predictive analytics powered by AI and enhanced technology for telemetry to control pressure in real-time. |

| Personnel Training | Specialized training required for teams that are not familiar with DGD systems | Virtual reality and advanced simulation platform (VR) tools for training |

| Equipment Reliability | Subsea components are exposed extreme conditions, and they can fail. | Design of stronger, more durable, high-performance subsea equipment |

| Regulatory Acceptance | Uncertainty in the global regulations can cause delays in the implementation of | International guidelines for the establishment of best methods to use Dual Gradient Drilling |

| Formation Variability | It is difficult to predict the formation response in Dual Gradient Drilling operations. | Control systems that adapt to machine learning to predict pressure and adjustment |

| Kick Response Protocols | Kick control strategies still evolving for dual-gradient environments | Automated well control systems integrating into Dual Gradient Drilling technology |

Final Thoughts

Dual Gradient Drilling is a major advancement in technology for enhancing well control, providing a more secure, more efficient, and economically viable method to manage challenging pressure environments. As offshore drilling moves into deeper and more complicated formations, DGD will likely become an essential tool in the arsenal of the industry, improving operational reliability and extending the frontiers of energy exploration.