What is Unconventional Drilling in Petroleum Industry

Unconventional drilling has transformed the oil and gas sector, unlocking energy resources once considered unreachable. This innovative approach goes beyond traditional vertical wells, tapping into complex geological formations with advanced techniques. Below, we’ll explore the basics, rise, key techniques, and applications of unconventional drilling.

Basics of Unconventional Drilling

Unconventional drilling in the oil and gas industry is specialist methods used to extract oil and natural gas from unconventional reservoirs—those in which hydrocarbons are trapped within low-permeability rock such as shale, tight sandstone, or coal bed. In these circumstances, oil and gas may not flow freely into a wellbore like it does in conventional reservoirs, so sophisticated technology is unavoidable.

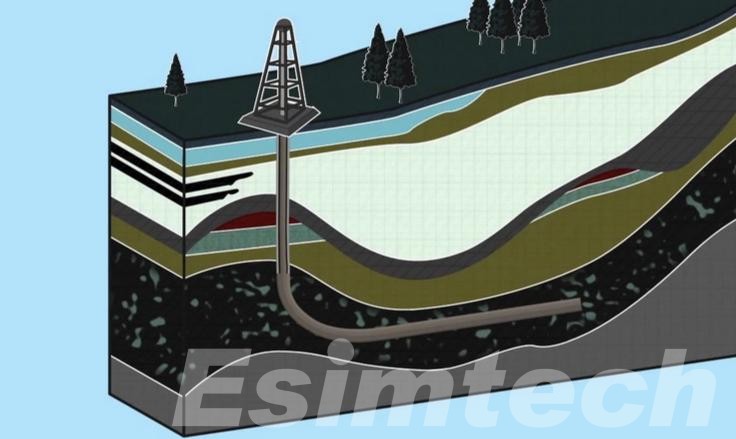

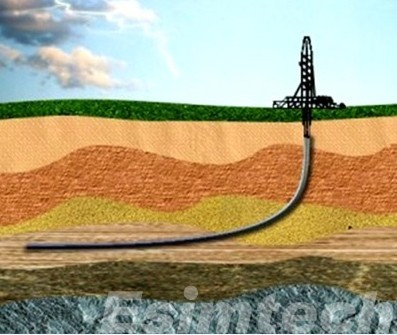

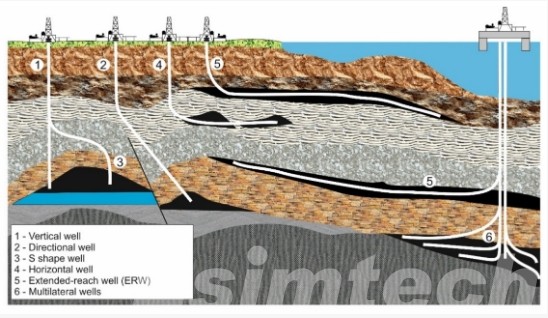

Traditional drilling typically follows a vertical well to a reservoir where pressure and rock facies are such that hydrocarbons have a free flow. Unconventional drilling, however, is inclined to use horizontal or directionally drilled wellbores to follow the productive bed along long intervals, maximizing contact with the reservoir.

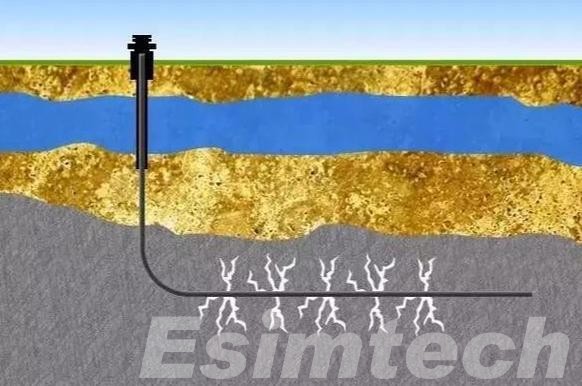

As a result of the density and impermeability of the rock, stimulation technologies—mostly hydraulic fracturing—are employed to create micro-fractures, enhancing flow pathways for hydrocarbons. Operations rely on precise geological mapping, customized drilling equipment, and robust well materials.

Unconventional drilling is not just an alternative technique—it is an integrated technique that combines engineering ingenuity with geoscience to bring resources that were considered uneconomical or inaccessible into production.

The Rise of Unconventional Drilling

The global shift towards nonconventional drilling emerged as a question of policy to respond to changing energy conditions. At the close of the 20th century, many easy-to-produce oil fields had reached the peak of their plateau, forcing operators into increasingly technically challenging reservoirs. Oil prices were high and energy security concerns were rising, triggering investment in alternative methods.

Advancements in directional drilling precision and rock stimulation science during the 1990s and early 2000s were a turning point. Pilot projects in low-permeability formation showed it was possible to economically produce hydrocarbons in shale and other tight rock at commercial rates. Governments and private money soon recognized the potential and envisioned big-time development of rich areas of unconventional reservoirs.

This transformation not only diversified global supply but also reshaped geopolitics, as countries with massive unconventional resources reduced their reliance on imports. Now, the advent of unconventional drilling is one of the most significant transformations in the modern petroleum market.

Key Techniques in Unconventional Drilling

Unconventional drilling relies on advanced engineering methods to release hydrocarbons from low-permeability, dense rock units. Of the many new methods developed, four are noteworthy for their impact on productivity, efficiency, and economic viability.

1. Horizontal Drilling

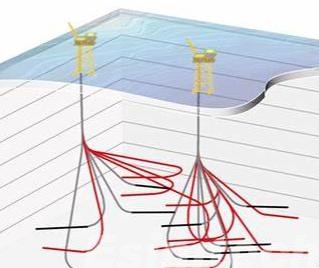

Horizontal drilling begins with a vertical wellbore that slowly deviates to parallel within the desired reservoir unit. This method greatly improves the area of contact between wellbore and hydrocarbon-bearing rock, with more oil or gas having access to the well. Horizontal wells in unconventional reservoirs—typically thin and laterally extensive—can extend thousands of meters, while operators can maximize volume from a single surface location. The precision of modern drilling equipment keeps the well within the optimum zone of production, conserving effort lost and enhancing recovery rates.

2. Hydraulic Fracturing (Fracking)

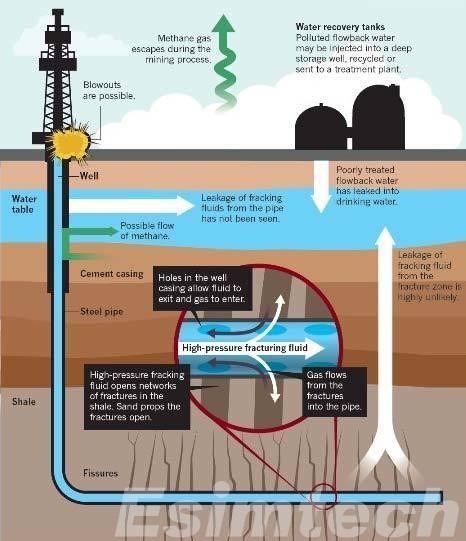

Hydraulic fracturing is a stimulation method that injects high-pressure fluid—typically water mixed with sand and chemical additives—into the rock to create microscopic cracks. These fractures act as conduits, allowing trapped hydrocarbons to move toward the wellbore. The sand, known as proppant, holds these fractures open after the pressure is released. Fracking is often performed in multiple stages along the length of a horizontal well, a process known as multi-stage fracturing, to ensure the entire productive zone is effectively stimulated. This technique is critical for making low-permeability reservoirs economically viable.

3. Extended-Reach Drilling (ERD)

Extended-reach drilling pushes the limits of how far a well may be deviated from its surface location. Operators are able to access resources beneath sensitive environments or offshore regions without placing rigs over the target by drilling hundreds of kilometers horizontally. ERD reduces the environmental footprint by lowering the number of well pads and allows a single drilling platform to develop multiple reservoir areas. The method demands tight wellbore stability control and mature drilling fluids to prevent mechanical issues.

4. Multilateral Drilling

Multilateral drilling creates multiple side-by-side wellbores from a single central well, each developing various parts of the reservoir. Multilateral drilling is a method of increasing reservoir drainage and production efficiency at reduced costs and without environmental risks of drilling separate wells. Multilateral configurations can be tailored to fit complicated geology and are consequently well-suited for complicated, variable-thickness or compartmentalized complex unconventional reservoirs. Selective intervention is also enabled by the technology, enabling operators to manage production from one branch independently.

These techniques—sometimes used in combination—are the backbone of unconventional drilling, transforming challenging geology into energy-producing resources.

Applications of Unconventional Drilling

Unconventional drilling has moved from the arena of experimental programs to becoming an industry staple for the extension of the supply of the world’s hydrocarbons. Its versatility allows operators to access a wide range of reservoirs that were once considered impractical or uneconomical.

1.Shale Resource Development

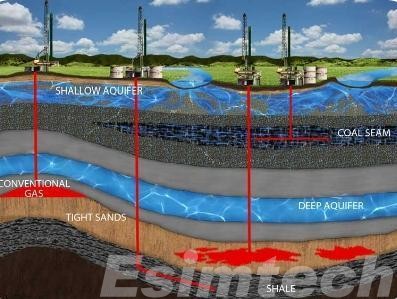

One of its strongest applications is in shale oil and gas plays. Such reservoirs contain vast quantities of hydrocarbons trapped in fine-grained rock. Horizontal drilling across shale intervals and multi-stage stimulation enable producers to expose continuous production over long well lives. Shale development has revolutionized energy markets by unlocking large, uniform domestic supplies in regions such as North America and portions of Asia.

2.Tight Sandstone and Carbonate Reservoirs

Tight gas and oil reservoirs are found in tight carbonate or sandstone rock with greatly restricted pore space. Here, unconventional drilling allows for making extensive reservoir contact, increasing the number of productive zones contacted per well. It is particularly beneficial in mature basins when conventional plays have already been depleted but significant hydrocarbons remain trapped in low-permeability horizons.

3.Coalbed Methane (CBM) Extraction

Coal seams contain a large proportion of the methane gas adsorbed on the coal surface. Unconventional drilling allows for efficient drainage of this gas by means of wells placed strategically to deplete the pressure of the seam. CBM production has become a notable supplementary source of energy in countries endowed with valuable coal deposits, offering a relatively low-carbon substitute for burning the coal itself.

4.Frontier and Environmentally Sensitive Areas

In regions where surface exposure is limited—below cities, wetlands, or preserves—unconventional drilling provides the potential to tap resources without actually crossing the surface over the reservoir. Multilateral and extended-reach wells can penetrate targets several kilometers away from the well location, with less environmental footprint and social disruption typical of conventional well placement.

5. Enhanced Recovery from Current Fields

Off-mainstream techniques can also revitalize developed oil and gas reservoirs. By horizontal drilling into unrecovered areas or fracturing tight sections in an established reservoir, operators can produce quantities once out of reach. Not only does this extend the economic life of a field but it maximizes the use of the resource, with less need for new exploration.

Overall, applications for unconventional drilling span numerous geological settings and conditions of operation. With access to complex reservoirs and the reduction of surface effects, it is now a critical tool in maintaining energy production consistent with environmental and economic considerations.

Final Thoughts

Unconventional drilling has revolutionized how the oil industry can access the world’s energy resources. By combining cutting-edge drilling technology with advanced stimulation techniques, operators can open up previously inaccessible reservoirs—meeting global demands while pushing engineering boundaries.