The Integration of Digital Twins into Reservoir Simulation

The oil and gas industry continues to develop towards digitalization, and the use of digital twins in reservoir simulation has emerged as a groundbreaking advancement. Digital twins in reservoir simulation can create dynamic, virtual replicas of physical reservoirs that update in real time, which allows for unparalleled levels of analysis, forecasting, and optimization. This article focuses on how digital twins are transforming reservoir simulation, as well as their main advantages, challenges to implementation, and future potential in hydrocarbon recovery.

Understanding Digital Twins in Reservoir Simulation

What are Digital Twins

Digital twins are continuous, real-time digital representation of the physical process or system used in oil and gas exploration. The digital model is the living model of the reservoir including information from geological models, sensors, past performance along with simulation data. The digital twin changes with the reservoir, changing when new data is available. It also allows forecasting as well as scenario-planning.

Role of Reservoir Simulation

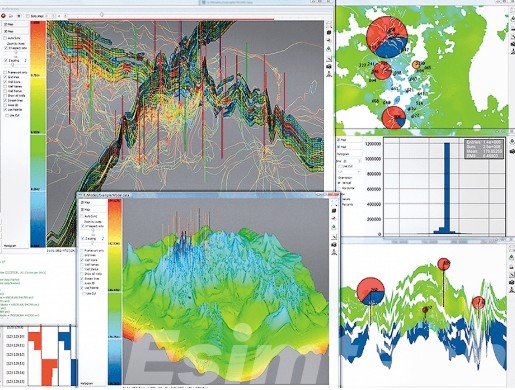

Reservoir simulation is the method of analyzing fluid flow through porous media in order to determine the performance and behavior of reservoirs. Traditionally, these models depend on static and historical data and are updated regularly. Although they are effective, they frequently fail to adapt to changes in the reservoir or unexpected behavior in production.

What are Digital Twins in Reservoir Context

Digital twins within reservoir engineering are a virtual model that replicates the physical behavior and conditions of a real reservoir system. As opposed to static models in conventional simulation The digital twin is developed constantly by integrating real-time field information such as temperature, pressure and production rates that are collected by sensors throughout the reservoir and its infrastructure. This creates a dynamic, rich in data environment that accurately represents the changes that occur of the reservoir’s condition over the course of time.

How the Integration of Digital Twins into Reservoir Simulation Works

1. Integrating Real-Time Data Streams

The initial step in integrating the digital twin in reservoir simulation is establishing the pipelines for data acquisition that are real time. Sensors and field instrumentation–such as downhole pressure gauges, flow meters, temperature probes, and seismic monitors–transmit continuous streams of data. The data is ingested via the digital twin system that connects the physical reservoir conditions to the simulation model.

This involves the utilization the Internet of Things (IoT) infrastructure, data lakes and communication protocols that guarantee safe, high-speed and secure storage and transfer of data. Data integrity and quality assurance are essential at this point to ensure the accuracy of modeling.

2. Updating the Reservoir Model Dynamically

After the digital twin has received real-time data from the reservoir, it continuously adjusts the reservoir simulation model. This is done by automatic recalibration of parameters, including porosity, permeability and saturation as well as pressure field. Advanced algorithms–including machine learning and data assimilation techniques–compare predicted versus actual field performance and adjust the model accordingly.

This feedback loop is closed, making the model more precise over time. This reduces the need for adjustments made manually, allowing engineers to identify early signs of deviation from the expected behavior and react proactively.

3. Simulation and Scenario Testing in Real Time

With a model that is constantly updated digital twins become an effective tool for forecasting based on scenarios. Engineers can model the impact of operational adjustments, like shifting injection strategies, establishing fresh wells or applying gas or water flooding before implementing them to the field.

These real-time oil and gas simulations are based on the most recent data, which makes their results more solid. This allows safe virtual experimentation that helps the decision makers to evaluate the trade-offs between production economics, environmental, and sustainability of the reservoir.

4. Incorporating Artificial Intelligence and Predictive Analytics

Artificial Intelligence (AI) plays an important part in improving the efficiency that digital twins play in simulation of reservoirs. AI-driven pattern recognition can detect anomalies in the behaviour of reservoirs like sudden pressure drop or the rapid breakthrough of water. Models of machine learning, which are trained using historical and current data, are able to predict the future performance of reservoirs under diverse circumstances.

This level of knowledge aids in optimizing production techniques, reduce the amount of non-productive time (NPT) and help to predict problems with reservoirs or equipment before they become a problem.

5. Enabling Collaborative and Integrated Decision-Making

Digital twins are generally stored on cloud-based platforms that enable remote collaboration between all stakeholders. Geoscientists, engineers, as well as asset managers have access to the same model in real time to ensure the sameness of decision-making. This integration can also help facilitate multidisciplinary workflows where models for reservoir simulation and production forecasting along with financial models are connected by a single system.

This type of collaboration is especially valuable when it comes to marginal or complicated areas in which multidisciplinary collaboration is crucial in unlocking the economic benefits.

Benefits of Integrating Digital Twins into Reservoir Simulation

1. Real-Time Reservoir Monitoring and Response

Digital twins give a live perspective of reservoir conditions through continuously consuming data from sensors incorporated into wells and other surface facilities. The monitoring in real-time lets engineers track the temperature, pressure saturation, pressure, and changes in flow patterns as they occur which allows faster responses to operational issues like water leaks or pressure drop, or issues with well integrity. Being able to monitor the changes that occur enhances the awareness of situations and improves the operational control.

2. Enhanced Forecasting and Predictive Capabilities

One of the biggest benefits of integrating digital twins in reservoir simulation is increased forecasting accuracy. Traditional models typically depend on assumptions and snapshots of data, which might not accurately reflect the current conditions of the reservoir. Digital twins are continually updated with real-time information and can provide more reliable forecasts of future performance. This makes it easier to plan to develop fields, optimize production and Enhanced Oil Recovery (EOR) methods.

3. Continuous Model Calibration and Reduced Uncertainty

Digital twins facilitate the process of calibrating models and reduce the amount of manual work required to adjust reservoir parameters. When new data enters the system, machine-learning algorithms and techniques for data assimilation modify the model simulation to reflect the performance of the field. Continuous recalibration reduces the uncertainty of simulation results, making them more reliable and lessening the possibility of erroneous operational decision-making.

4. Accelerated Decision-Making and Operational Efficiency

With an up-to-date, single data source, the digital twins break down the silos of data and bring teams of different functions with the same reservoir knowledge. Decision-making is faster and more certain, and is backed by precise up-to-date information. Engineers can create scenarios – such as increasing the rate of injection and modifying lift methods or drilling new wells, and evaluate the results in close-to-real time. This flexibility results in faster process times for project approvals and operational changes.

5. Optimization of Production Strategies

Digital twins let operators examine different production strategies virtual before committing resources to the field. By simulating different “what-if” cases using the most recent reservoir information, companies can decide which one has the highest performance in terms of recovery rate and cost-efficiency and long-term sustainability. The oil and gas production simulations decrease the dependence on costly field tests and helps improve long-term management of reservoirs.

6. Early Detection of Anomalies and Risk Mitigation

With the help of patterns recognition as well as AI analytics Digital twins are able to detect any irregularities in the behavior of reservoirs that could signal potential problems like production and scaling or sudden declines in efficiency. The early detection of problems can lead to proactive maintenance, less downtime, and avoiding costly malfunctions. The shift from proactive to reactive operations increases the overall reliability of assets and increases safety.

7. Improved Collaboration Across Disciplines

The digital twin functions as a common platform for reservoir engineers, geoscientists production teams, as well as management. Everyone is working using the same model in real-time which allows for greater communication and coordination in decision-making. This workflow is integrated, which reduces inefficiencies and helps align reservoir strategies, especially in fields that are complex or unorthodox.

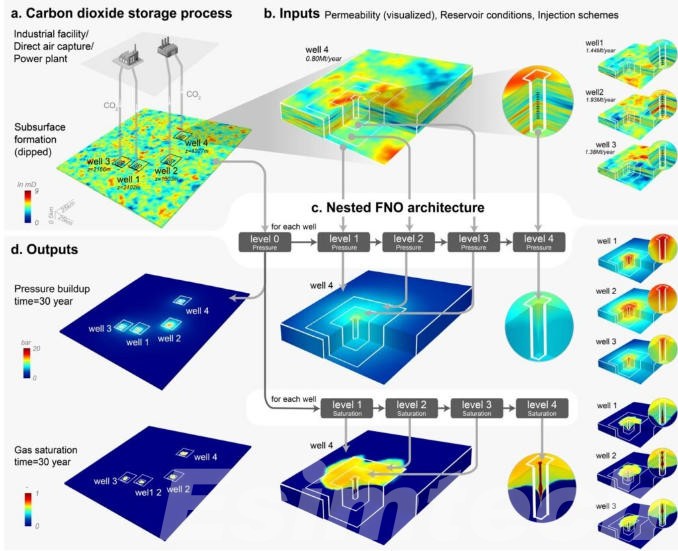

8. Better Support for Sustainability and Environmental Goals

Digital twins allow for greater control of the behavior of reservoirs and also aid in environmental performance. A more efficient production process reduces energy use as well as better monitoring assures that injection and production processes conform to environmental and regulatory requirements. When it comes to carbon capture and storage (CCS) operations digital twins can help monitor CO2’s movement underground, improving the safety of workers and ensuring accountability.

9. Competitive Advantage and Long-Term Value Creation

The adoption of digital twins in reservoir simulation gives operators a an advantage. By maximizing recovery, reducing operational risk and streamlining their decision-making processes, businesses can boost profitability and increase the value of assets. Additionally, the technology can support long-term goals for strategic planning, like digital transformation and energy transition, preparing companies for the future of resilience.

Challenges and Solutions in Implementing the Integration of Digital Twins into Reservoir Simulation

| Challenge | Description | Solution |

| Data Quality and Availability | Uncomplete data, noisy, or out of date information can affect model accuracy. | Set up high-resolution sensors, and then implement strict cleaning and data validation protocols. |

| Legacy Infrastructure | Some older fields aren’t equipped with the technology needed to allow real-time updates. | Modernize the instrumentation and incorporate the latest IoT or SCADA systems to ensure uninterrupted data stream. |

| Computational Complexity | Real-time simulations and massive data volumes require a lot of processing power. | Make use of cloud computing or HPC (HPC) platforms in order to increase the scale of the tasks of simulation. |

| System Integration Difficulties | Multiple data and software sources can be incompatible. | Utilize open data standards APIs, middleware, as well as open data standards to ensure effortless integration with other platforms. |

| Lack of Skilled Workforce | Engineers may not be knowledgeable about AI or data science or digital twin technology. | Develop specific training programs and work with technology partners to share knowledge. |

| Organizational Resistance to Change | Moving between traditional and digital ones may be met with resistance. | Develop a digital-first mindset and show ROI with trials and success stories. |

| Cybersecurity and Data Privacy Concerns | The increased connectivity increases the possibility of data breaches and system-wide attacks. | Set up robust security frameworks as well as encryption protocols along with access control and security systems. |

| High Initial Investment Costs | Digital twin systems may be costly. | Begin with small-scale, high-impact trials and then adopt phases-based implementation strategies. |

Future Outlook in the Integration of Digital Twins into Reservoir Simulation

The future of using digital twins in reservoir simulation promise smarter, faster and more sustainable reservoir operations powered by edge computing and data-driven strategies.

Expanding Scope Beyond Oil and Gas

Digital twins have demonstrated their worth in traditional reservoirs of hydrocarbons, their use is likely to expand substantially. In the near future they will be a crucial component in the management of geothermal reservoirs, carbon storage and capture (CCS) monitoring and hydrogen storage where analyzing and controlling the behavior of subsurface systems is essential. Digital twins have been positioned as a tool that can be used to manage subsurface energy systems during the phase of low-carbon transition.

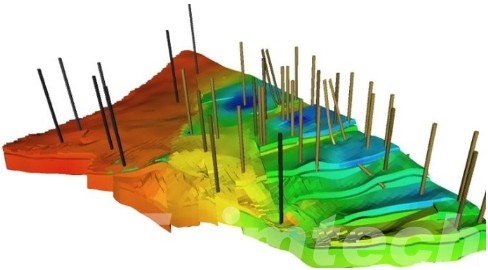

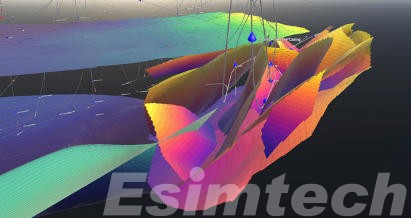

Enhanced Visualization and Immersive Technologies

In the near future in the near future, the advent of augmented reality (AR) and virtual reality (VR) will improve the way engineers communicate with digital twins. These tools that are immersive will offer 3D rendering of the dynamic behavior of reservoirs aiding users to comprehend fluid motion as well as pressure distribution and the interactions between fluids and rocks. This will help improve training as well as collaboration and decision-making across geographically dispersed teams.

Cloud-Native and Edge Computing Expansion

As the digital twins of reservoirs increase in complexity, navigating the huge volume in data requires a mix of cloud-native architectures as well as edge computing. Cloud platforms will allow central model and historical analytics and edge devices that are installed at field sites can handle data locally, decreasing latency and enabling instantaneous responses. This hybrid approach will ensure rapidity, scalability and stability.

Increased Standardization and Interoperability

In order to facilitate widespread adoption, the industry will shift towards standard data formats, open-source modeling frameworks, as well as API-based integration. These developments will allow various suppliers systems, disciplines, and platforms to collaborate seamlessly within the digital twin ecosystem which will reduce the cost of customization and encouraging cooperation between service providers and regulators.

Integration into Sustainability and ESG Goals

The future digital twins of the future will play a key role to sustainable strategies. They can help optimize water use as well as monitor emissions, manage the consumption of energy, and also ensure that regulatory compliance is met. In CCS projects digital twins are used to monitor the flow of CO2 and look out for leakage risk while also ensuring environmental safety and establishing trust among the public. They’re an essential instrument in achieving ESG (Environmental Social,, and Governance) goals.

Democratization Through Low-Code and No-Code Platforms

The complex nature in digital twin systems has restricted their application to data scientists and specialists in engineering. In the near future low-code and no-code interfaces will open access to the data which will allow reservoir engineers as well as field operators to create configuration, manage, and interact with digital twins even without a deep programming skills. This will increase adoption and increase operational agility.

Increased Emphasis on Cybersecurity and Digital Governance

As digital twins are more closely integrated with infrastructure operations, cybersecurity will be an essential concern. The coming years will see a greater investments on secure virtual twins that include real-time threat detection multi-factor authentication, as well as blockchain-based data integrity solutions to protect mission-critical operations.

From Project-Level to Asset-Level Digital Twins

While the current systems tend to concentrate on particular reservoirs or wells, the upcoming generations of digital twins are expected to cover entire asset portfolios or fields. These twins for enterprise will connect multiple pipelines, reservoirs, processing units and even market data in order to optimize not only technical performance, but also logistical and financial outcomes across the entire value chain.

Final Thoughts

The integration of digital twins into reservoir simulation is a new era in subsurface management. Through the combination of real-time data, advanced analytics and simulation capabilities, digital twins enable energy companies to make smarter, faster, and safer decisions. As the industry continues to advance, the use of digital twins is likely to be a key component of digital oilfield of the future, increasingly sophisticated, incorporating more AI capabilities and expanding their roles in the energy transition. Oil and gas companies are able to successfully implement this technology will have significant competitive advantages in the evolving energy market.