Effective Hole Cleaning Techniques for Oil and Gas Drilling

Effective hole cleaning is essential to for successful drilling operations. It directly affects the rate of penetration, wellbore stability, equipment integrity and overall drilling efficiency. As the industry develops towards deeper, more complicated wells, the hole cleaning technologies have also been advanced to address new challenges. This article focus on the key techniques and methods used for effective hole cleaning in both vertical and directional wells.

Why Hole Cleaning is Critical in Drilling Operations

- Preventing Stuck Pipe and Wellbore Instability

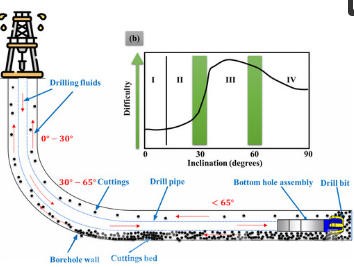

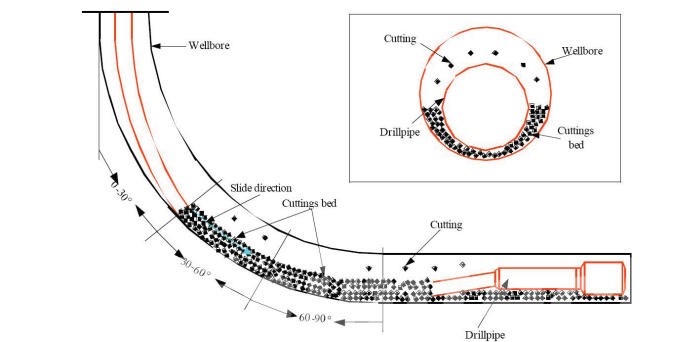

One of the main reasons why hole cleaning is so important is the role it plays in preventing accidents with a stuck pipe. If the cuttings build up in the annulus and they are not properly removed and disposed of, they may create a bed of cuttings that entraps drilling string. This can not only stop drilling, but also requires expensive sidetracking or fishing techniques. Furthermore, poorly-maintained holes cause wellbore instability. In this case, the borehole caves in due to irregular pressure distribution and an erosion process that damages the walls of the formation.

- Maintaining Rate of Penetration and Reducing Mechanical Risk

Drilling performance is tightly tied to the state of the bore. As the debris accumulates, it increases friction on the drilling string which leads to a higher drag and torque. This may decrease your rate of penetration (ROP) as well as result in premature wear of drill bits and put more strain on equipment and surfaces. The efficient cleaning of holes ensures that cuttings are always delivered to the surface ensuring the drill bit is in top condition and ensuring the same pace without the need for mechanical setbacks.

- Enhancing Drilling Fluid Circulation and Cuttings Transport

Drilling fluids are specifically designed to fulfill a number of critical tasks, such as cool the drill bit down, sustaining wellbore pressure, as well as transporting cuttings. In order for these functions to function efficiently, the annular space must be free of obstructions. A poor hole cleaning can disrupt circulation patterns, reducing cut-off efficiency transportation and may result in leaks or pressure imbalances. Clean holes ensure your drilling solution functions in the way it was designed, thus maximizing the efficiency of operations.

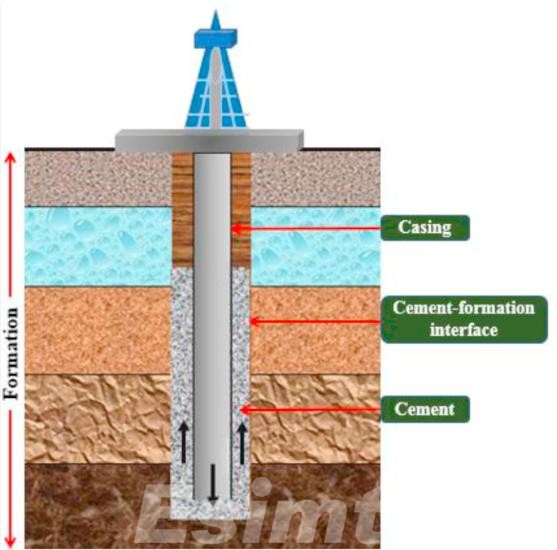

- Improving Cementing Quality and Well Integrity

Well cementing is a crucial step during the drilling process that creates an impermeable seal between the formation and the casing to stop fluid movement and to ensure the structural strength. An unclean wellbore is vital for the formation to have a solid cement bond. The leftover cuttings and filter cake could act as barriers, leading to low displacement effectiveness in weak bonding. A thorough cleaning of the hole increases the chances of achieving complete isolation of the zone and also long-term integrity of wells.

- Reducing Non-Productive Time and Operational Costs

The amount of non-productive time (NPT) caused by problems with cleaning holes can raise drilling costs. Situations like stuck pipes and wiper trip, as well as cleaning procedures that are remedial in nature consume the rig's time and resources. Monitoring and controlling hole cleaning with efficient drilling fluid systems, mechanical tools and real-time monitoring reduces the risk. It also facilitates more precise planning and quicker drilling that ultimately leads to a reduction in the total cost of wells.

- Supporting Automation and Advanced Drilling Techniques

With the advent of digital drilling technology and automated drilling, maintaining constant conditions in the downhole is becoming more important. sensors and data systems that are real time depend on a predictable behavior of the wellbore to feed machine learning algorithms, as well optimization software. Insufficient hole cleaning causes noise to enter these systems, which reduces their efficiency. By making sure that the wellbore remains clear as well as free from obstructions operators are able to make the most of the latest drilling technology and increase the accuracy of their decision-making.

Key Hole Cleaning Technologies Used during Drilling Operations

As drilling operations increasingly target complex reservoirs with longer laterals and deeper formations, traditional approaches to hole cleaning have given way to more advanced, integrated techniques.

1. Optimizing Drilling Fluid Properties

The basis of efficient hole cleaning is the precise design and control drill fluids. By altering the properties of a fluid, such as density, viscosity, and the strength of gels, technicians can enhance the ability of the fluid to hold and transport cuttings onto the surface.

Drilling muds that have the right properties for rheology can produce enough annular velocity, especially in horizontal or deviated sections where gravitational forces are not as efficient. High-performance synthetic and water-based mud systems are typically used due to their superior thermal stability, lubricity as well as their capacity for suspending solids. In certain instances the addition of additives is to increase the strength of gels and prevent cuttings from sinking in the event of pump shut-offs.

2. Managing Flow Rate and Drill String Rotation

Controlling the flow rate and string rotation is a key method for ensuring efficient hole cleaning. More flow rates can increase the annular speed, and this is vital to lift cuttings from horizontal or extremely deviated wells. This is crucially vital in extended-reach wells, in which long intervals need to be cleaned across large distances.

While rotating, the drill string assists in agitating the cuttings that are settling on the bottom of the drill, delaying the cuttings from forming bed formations. When drilling in complex wells, constant rotation is crucial to keep cuttings suspended and mobile.

3. Downhole Tools

Downhole tools has become a common method of removing stubborn cutting buildup and increasing the effectiveness of cleaning.

Reamers, as well hole openers help in enlarging the bore while moving the annular space to eliminate the solids that have accumulated. Jetting subs, that send high-pressure fluid flows towards the wall of formation and are utilized to break up the cuttings bed and enhance fluid flow. Furthermore, downhole agitators as well as vibratory instruments help break up sedimentation by generating mechanical oscillations which lift and carry debris.

These tools are often deployed strategically--either continuously or during specific intervals, depending on the complexity of the well and the rate of cuttings accumulation.

4. Implementing High-Viscosity Sweeps and Cleaning Pills

If the normal circulation of fluids isn't enough, managers can employ high-viscosity cleansing pills to achieve specific goals. These specialized slugs made with a high viscosity, can be pumped down the well to release the accumulated debris and remove it from narrow zones or horizontal segments.

Sweeps are made of unweighted or weighted fluids and could also include chemical components which break down the cakes of filtering or sticky clays for formation. They are especially useful in times of low circulation, for instance when connecting or tripping pipes.

5. Real-time Monitoring and Predictive Modeling

In today's drilling conditions monitoring in real-time is crucial to increasing the effectiveness of cleaning holes. Sensors on downhole equipment and surface tools offer continuous information regarding parameters such as cuttings size as well as drag, torque, in addition to annular pressure.

Advanced software utilizes this information to analyze fluid dynamics in the wellbore and forecast the growth of cuttings beds. These models can aid operators in adjusting mud property, the flow rate or the movement of drill strings prior to problems escalating, greatly cutting down on time spent in non-productive work.

Certain rigs also employ visual analytics on the shaker for shale to gauge cuttings ' size and volume and provide feedback on the extent to which cleaning the holes is going on.

6. Tailoring Techniques for Well Geometry

Hole cleaning methods need to be tailored to the particular shape that the particular well has. In vertical wells, gravity assists in moving cuttings upwards which makes the regular circulation and mud properties typically adequate. However, in extremely horizontal or deviated wells, a customized approach is needed.

This can include a combination of greater flow rates mechanical agitation, special system for mud, and continuous rotating drill strings. For long sections of lateral length employing spiral stabilizers or eccentric tools could improve cuttings transportation through enhancing flow patterns.

Challenges and Solutions in Hole Cleaning for Drilling Operations

This chart outlines the challenges and solutions associated with cleaning holes during drilling operations, providing a comprehensive overview of how to overcome the complexities of maintaining a clean and efficient wellbore.

| Challenge | Description | Solutions |

| Cuttings Accumulation | Inadequate cleaning of holes can result in the accumulation of drill cuttings that could cause stuck pipe as well as slowing the progress of drilling. | The use of high-viscosity drill fluids for suspending and move cuttings. Use high-viscosity scrubs or cleaning pills to agitate cut-offs that have settled. Mechanical tools such as jetting subs and agitators to remove and disperse obstructions. |

| Reduced Rate of Penetration | The accumulation of cuts increases friction which may reduce the speed of penetration, which can affect the overall effectiveness. | Optimizing the fluid rheology in order to increase cuttings' mobility and reduce drag. The increased flow rate and the continuous drill string rotation in order to maintain momentum and prevent sticking. Ensure that you regularly clear cuttings to keep bits running efficiently and improve ROP. |

| Poor Hole Stability | Cuttings buildup can weaken wellbore and cause instability and possibly collapse, particularly in soft formations. | Keeping wellbore pressure maintained by using controlled pressuring (MPD) system. Utilization of reamers or vibratory tools to ensure that the hole remains open and avoid damage to the formation. Monitoring stability of the wellbore in real-time, allowing you to perform corrective actions if necessary. |

| Deviated and Horizontal Well Challenges | In horizontal and deviated wells gravity is less efficient at removing cuts and causing accumulation in the lower part of the well. | The increase in flow rates will improve annular velocity and the removal of cuts. Continuous rotation of the drill string and eccentric tools to move cuttings around and encourage upward flow. Use the spiral or eccentric stabilizers to increase mud flow and reduce the risk of cuttings building up. |

| Non-Productive Time | Inefficient cleaning of holes can lead to delay in drilling such as stuck pipes, as well as time-consuming cleaning operations. | Monitoring in real-time of drag, torque and cuttings volume in order to spot early warning indications. Advanced software and predictive modeling to automatically adjust the drilling parameters. Regular inspections of equipment and troubleshooting to reduce unexpected downtime. |

| Tool Wear and Damage | Cuttings that accumulate increase the friction and wear on reamers, drill bits and other tools for drilling downholes and reduce the lifespan of tools. | Use high-performance lubricating systems to decrease erosion and friction on equipment. Utilizing bit cleaners, and using specially designed tools to ensure tool effectiveness and decrease wear. Change the drilling parameters regularly to reduce wear and tear during the course of operations. |

| Fluid Loss and Poor Cementing | The accumulation of cuttings and the inadequate circulation of fluids can result in inadequate cementing, which weakens well the integrity. | Utilizing cleaner, lower-solids fluids to ensure the proper displacement of the cuttings when cementing. Adjusting mud weights and chemical additives in order to improve the quality of cement bonds. - Implementing the proper cleaning protocols prior to cementing operations in order to ensure that the wellbore is clean. |

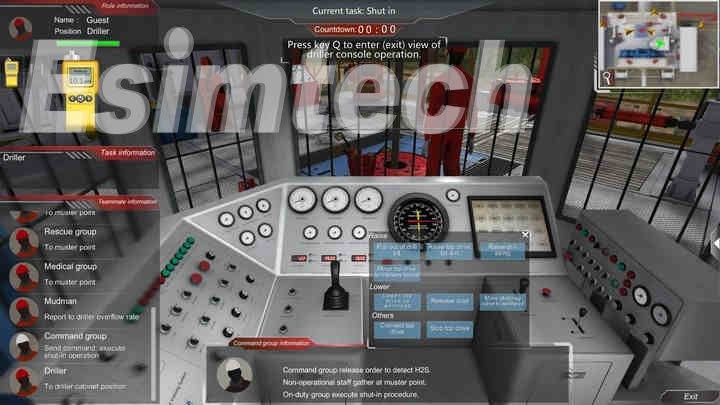

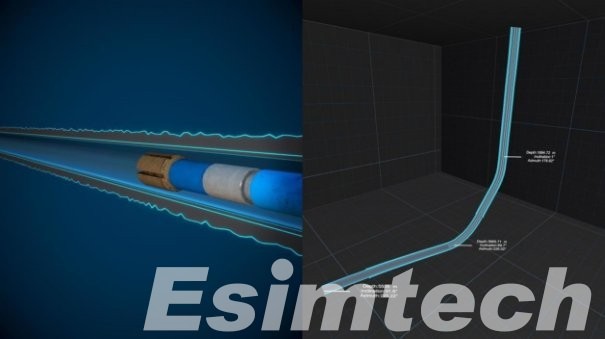

How Simulation Technology is Used for Hole Cleaning During Drilling Operations

By leveraging the advanced software and real-time data, oil and gas simulation technology allows operators to predict, monitor and improve the process of cutting transport in complex drilling conditions. From vertical wells to horizontal and extended-reach wells, simulation offers crucial insights that lead to more efficient hole cleaning, which improves rate of penetration, and ensuring wellbore stability.

- Real-Time Fluid Dynamics and Cuttings Transport Modeling

Simulation technology allows the simulation of fluid dynamics in the wellbore. It provides real-time view of the way drilling fluids interact with cuttings. Advanced software allows for the simulation of the behaviour of mud cuttings, mud, and wellbore's surroundings, anticipating the ways that conditions in the wellbore like the flow rates, fluid flow and the geometry of the wellbore can impact the transportation of cuttings.

Inputing specific parameters, such as trajectory, mud properties, and flow rates, simulator tools can estimate the best environment for lifting and moving cuts to the ground. These models can help predict possible issues, like the accumulation of cuttings in low-side areas, or backflow in wells that are deviated, which allows operators to modify drilling parameters before problems arise.

- Optimizing Flow Rates and Mud Rheology

Simulations let operators experiment with different flow rates and mud rheology mixtures without the expense of costly and time-consuming trial and error in the field. By simulating a variety of mud densities, viscosities along with flow and temperature conditions engineers can determine the most efficient combination of cuttings suspension and transportation.

For instance, in heavily inclined or horizontal wells, simulations are able to determine the flow rates needed to maintain a sufficient annular velocity, which will ensure that the cuttings are transported up to the surface. Additionally, these models allow you to improve the properties of mud in real-time, altering the rheology in order to maximize the cleaning of holes during various stages of drilling, including during connection break-ups or when traveling.

- Predicting Cuttings Accumulation and Settling

Simulation tools can help predict where cuttings are likely collect and settle in the wellbore by analyzing the trajectory of the well as well as mud flow patterns and cuttings ' size. This ability to predict is essential to avoid common problems with hole cleaning like stuck pipe with excessive torque and slow drilling speeds.

For instance for horizontal wells in which gravity has a less impact, simulations can predict the areas where cuttings may be able to settle on the lower end and determine how much impact this could affect the efficiency of drilling. With this knowledge operators can improve flow rates, modify the speed of rotation of the drill string or apply sweeps and pills in strategic intervals to limit the chance of a buildup of cuttings.

- Real-Time Data Integration

Modern drilling rigs are outfitted with a range of sensors that offer real-time information on parameters like drag, torque as well as pump pressure and flows. Simulation technology blends this data with models predictive of the situation giving operators continuous insight into the efficiency of their hole-cleaning efforts.

For instance, if real-time data indicates that drag is growing and cuttings are growing and causing friction, the drilling simulators will quickly alter the drilling parameters to reduce the issue. This feedback loop that is real-time permits quick decision-making as well as dynamically optimizing the process, assuring an efficient cleaning of the hole through the whole drilling.

- Risk Assessment and Mitigation

Emergency simulation technology is a key element in the assessment of risk and mitigation during drilling operations. By simulating different wellbore conditions, such as varying flow rates, mud properties, or geological formations--operators can identify potential risks associated with cuttings transport and hole cleaning.

Simulations can help predict situations like stuck pipe accidents and wellbore instability or the loss of mud prior to it happening. This permits the drilling team to adopt proactive measures for changing the weight of mud, increasing the rate of circulation, or using mechanical tools for cleaning holes to stop these problems from affecting the drilling process.

- Optimizing Mechanical Hole Cleaning Tools

Simulation technology is a great tool to improve the placement and operation of mechanical tools to clean holes like reamers, jetting subs, and agitators. Through simulating the effects of these tools in particular conditions of the wellbore, operators can identify the most effective placement and operational parameters to ensure maximum efficiency.

Simulations, for instance, allow for the simulation of the effect of jetting sub's high-pressure nozzles on clearing the debris away from the wellbore. Through testing various nozzle angles as well as flow rates and tool configurations during this simulation model, engineers will be able to find the optimal setting to maximize the efficiency of these tools.

- Enhanced Decision-Making using Scenario Analysis

Simulation tools let operators run scenarios analysis, testing different "what-if" situations before they take place during field operations. This is particularly helpful when developing complex drilling processes, for example, extended-reach or deepwater wells, in which cleaning the hole is more difficult.

Simulating different types of mud flow rates, mud types, and mechanical tool configurations in different drilling conditions, drillers can assess the most effective ways to ensure the highest quality cleaning of the hole and decrease the possibility of failure. The ability to test preemptively strategies helps in making better decisions and decreases the risk of failure during drilling.

Future Trends in Hole Cleaning Technology for Drilling Operations

As drilling operations become more complex and target deeper, more challenging reservoirs, hole cleaning technology is advancing to meet these new demands.

Autonomous Hole Cleaning Systems

The future of technology for cleaning holes will be characterized by the development of fully autonomous systems that are capable of real-time monitoring analysis, adjustments, and monitoring without the intervention of humans. They will incorporate sophisticated sensors, real-time analysis of data and AI to constantly evaluate the condition of the wellbore and improve cleaning efficiency.

The systems can make instantaneous decisions to modify parameters such as pressure, mud flow rate or even triggering an application of tools that are mechanical (e.g. jetting subs or Reamers) in response to the conditions of the downhole. This will eliminate the requirement to use manual interventions, increase operational safety, and boost efficiency by ensuring that the cleaning of holes remains at an optimal level during drill process.

Smart Drilling Fluids and Additives

Technology advancements in drilling fluids will result in smarter fluid systems that are more flexible. Drilling fluids of the future will be developed with sensors built-in or additives that will alter their properties in response to real-time conditions within the wellbore. For instance, fluids can automatically adjust their viscosity and density depending on changes in temperature, flow rate or pressure, enhancing the ability of transferring cuttings.

Furthermore there will be more emphasis on the development of eco-friendly and sustainable drilling fluids. Bio-based fluids as well as low-toxicity additives are becoming more popular and the next developments will likely be focused on lessening the environmental impact of drilling operations as well as increasing the efficiency of hole cleaning.

Hybrid Hole Cleaning Methods

Hybrid systems that mix different technologies will become more widespread. For instance the usage of a blend conventional mechanical equipment (like reamers, agitators, as well as jetting subs) together with the most advanced fluid technology (smart foams, fluids or high-viscosity sweeping) can optimize the cleaning of holes for complex wellbore conditions.

Hybrid systems can be adapted to various types of wells which include deviated, vertical, or horizontal ones. The ability to blend various methods allows operators to modify the method of cleaning holes in real-time based on the conditions of the well increasing efficiency and lessening the risk of cutting accumulation and other problems.

Advanced Downhole Tool Integration

The future of cleaning holes will be the further integration of sophisticated downhole equipment that can enhance cuttings' transport. These advanced downhole tools include vibrators, reamers and jetting subsystems outfitted with sensors, as well as AI algorithms to improve efficiency in real-time. These instruments will be able identify the existence of cuts or changes in the wellbore's conditions, and adjust their operation to increase the effectiveness of cleaning.

For instance advanced jetting subs can alter their nozzle angles or pressure based on the amount of cuttings that are accumulated to ensure continuous cuttings transportation with minimal loss of fluid and enhancing the stability of the wellbore. In addition, new tools could be developed to offer cleaner and targeted cleaning in critical drilling stages for example, when making connections or when running in and out from the bore.

Summary

Hole cleaning techniques are a dynamic intersection of fluid mechanics, mechanical engineering and digital monitoring. As oil and gas drilling moves into more demanding environments, the integration of smart tools, real-time data and sophisticated fluid systems is vital. Implementing effective hole cleaning techniques not only enhances the safety and efficiency, but also guarantees greater efficiency in well delivery.