Real-Time Monitoring Systems and Decision Support Tools in Oil and Gas Drilling

In the fast-paced and demanding world of oil and gas drilling, integrating real-time monitoring systems and decision support tools has become critical for optimizing operations, maintaining safety, and increasing efficiency. This article delves into the significance of real-time monitoring systems and decision support tools in oil and gas drilling, highlighting their functionalities, benefits, and impact on industry practices.

Real-Time Monitoring Systems in Oil and Gas Drilling

Real-time monitoring systems play an important role in oil and gas drilling operations by providing drilling staff with essential data insights for decision-making, safety, and efficiency. These systems use advanced sensors, telemetry technology, and data analytics to constantly monitor numerous factors and situations throughout drilling operations.

1. Drilling Parameters Monitoring

Real-time monitoring systems track essential drilling parameters such as weight on bit (WOB), torque, rate of penetration (ROP), rotary speed, and mud properties. By monitoring these parameters in real-time, operators can assess drilling performance, detect anomalies, and optimize drilling operations for maximum efficiency.

2. Wellbore Condition Monitoring

Real-time monitoring systems evaluate the condition of the wellbore, including pressure, temperature, and fluid levels. Monitoring wellbore conditions assists operators in detecting potential wellbore instability concerns, fluid influxes, or gas kicks, allowing them to take proactive steps to maintain wellbore integrity and avoid drilling hazards.

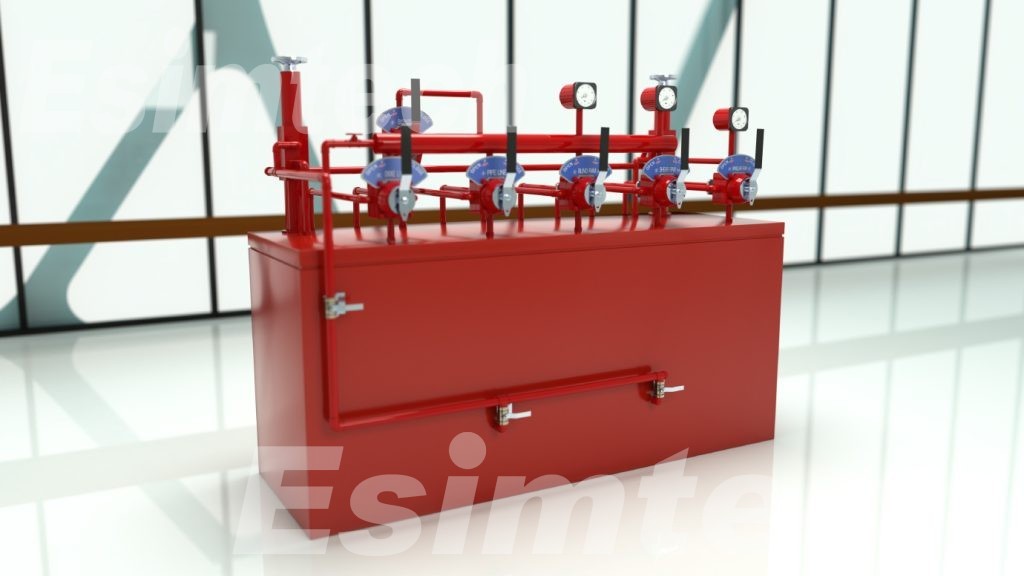

3. Equipment Health Monitoring

Real-time monitoring systems track the health and performance of drilling equipment such as pumps, motors, and drill bits. By monitoring equipment parameters such as temperature, vibration, and operating pressures, operators can identify potential equipment failures or malfunctions and implement preventive maintenance measures to minimize downtime.

4. Safety Monitoring

Real-time monitoring systems provide critical safety monitoring capabilities, detecting potential safety hazards such as kicks, blowouts, or well control incidents. By continuously monitoring wellbore pressures, fluid levels, and other safety indicators, operators can implement timely interventions to ensure the safety of personnel and assets on the drilling rig.

5. Environmental Monitoring

Real-time monitoring systems track environmental parameters such as air quality, noise levels, and emissions. Monitoring environmental conditions helps operators ensure compliance with regulatory requirements and minimize the environmental impact of drilling operations.

6. Data Visualization and Analysis

Real-time monitoring systems provide data visualization and analysis tools that enable drilling personnel to visualize real-time data streams, trends, and anomalies. Advanced analytics capabilities help identify patterns, predict potential issues, and optimize drilling parameters for improved performance and efficiency.

7. Remote Monitoring and Control

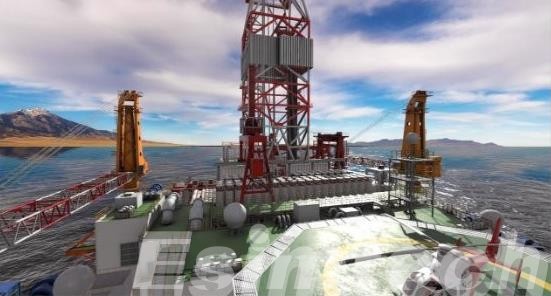

Real-time monitoring systems support remote drilling monitoring and control capabilities, allowing drilling personnel to monitor drilling operations from remote locations and make real-time adjustments to drilling parameters as needed. Remote monitoring capabilities enhance operational flexibility and efficiency, particularly in offshore or remote drilling environments.

8. Integration with Decision Support Tools

Real-time monitoring systems integrate with decision support tools and software platforms, allowing operators to use real-time data insights to make educated decisions. Decision support tools assess real-time data streams, forecast future trends, and offer the best drilling tactics to improve safety, efficiency, and production.

Decision Support Tools in Oil and Gas Drilling

Decision support technologies are vital assets in the oil and gas drilling sector, helping operators make educated decisions, optimize drilling operations, and reduce risks. These systems use advanced analytics, modeling methodologies, and real-time data to give drilling operators relevant insights and recommendations.

1. Real-Time Data Analysis

Decision support tools analyze real-time drilling data streams, including parameters such as weight on bit, rate of penetration, mud properties, and wellbore conditions. By processing and analyzing this data in real-time, DSTs identify patterns, trends, and anomalies, enabling operators to make timely decisions and adjustments to drilling parameters.

2. Predictive Analytics

Decision support tools employ predictive analytics techniques to forecast future drilling performance, wellbore stability, and equipment health. By analyzing historical data and drilling trends, DSTs predict potential drilling hazards, equipment failures, or wellbore instability issues, enabling operators to implement proactive measures to mitigate risks.

3. Optimization Algorithms

Decision support tools utilize optimization algorithms to identify optimal drilling parameters and strategies for maximizing efficiency and productivity. These algorithms consider various factors such as formation characteristics, wellbore conditions, and equipment capabilities to recommend optimal drilling trajectories, mud properties, and drilling techniques.

4. Risk Assessment and Mitigation

Decision support tools conduct risk assessments to identify potential drilling risks and vulnerabilities. By analyzing data on wellbore pressures, formation properties, and drilling conditions, DSTs assess the likelihood and impact of various risks such as kicks, fluid losses, or equipment failures. Based on these assessments, operators can implement risk mitigation measures and contingency plans to ensure drilling safety and reliability.

5. Cost-Benefit Analysis

Decision support tools perform cost-benefit analysis to evaluate the economic feasibility of drilling operations and investment decisions. By considering factors such as drilling costs, production potential, and market conditions, DSTs help operators assess the profitability and risk exposure of drilling projects, enabling informed decision-making and resource allocation.

6. Visualization and Reporting

Decision support systems offer data visualization and reporting capabilities, allowing drilling operators to see drilling data, trends, and insights in simple graphical formats. Visualization tools improve data interpretation and communication, allowing drilling teams and stakeholders to make more collaborative decisions.

Simulation Technology Used in the Real-time Monitoring Systems and Decision Support Tools

1. Drilling Process Simulation

Simulation software models the drilling process, including downhole dynamics, fluid behavior, and wellbore stability. By simulating different drilling scenarios, operators can assess the impact of various parameters on drilling performance and safety. This information is crucial for optimizing drilling parameters in real-time and identifying potential drilling hazards.

2. Digital Twin Modeling

Digital twin technology creates virtual replicas of drilling equipment, wellbores, and surrounding geological formations. These digital twins enable real-time monitoring and analysis of equipment health, wellbore integrity, and drilling performance. By comparing real-time data from the field with the digital twin model, operators can identify deviations, predict equipment failures, and implement preventive maintenance measures.

3. Geological and Reservoir Simulation

Simulation tools are used to model geological formations and reservoir properties, providing insights into subsurface conditions and hydrocarbon reservoir behavior. By integrating geological and reservoir simulation data with real-time drilling data, operators can optimize well placement, mitigate drilling risks, and maximize hydrocarbon recovery.

4. Dynamic Wellbore Hydraulics Simulation

Simulation software models fluid flow dynamics within the wellbore, predicting parameters such as pressure, flow rate, and mud properties. Real-time monitoring of wellbore hydraulics enables operators to detect drilling fluid losses, kicks, or wellbore instability issues promptly. By simulating different mud properties and circulation rates, operators can optimize drilling fluid properties and maintain wellbore stability.

4. Decision Support System Simulation

Decision support systems use simulation models to assess drilling data, forecast future trends, and recommend the best drilling tactics. Machine learning algorithms and predictive analytics are used to detect trends in historical data and generate actionable insights for real-time decision-making. Decision support systems assist operators in optimizing drilling performance, mitigating risks, and increasing efficiency by modeling various drilling scenarios and analyzing potential outcomes.

Case Studies in Oil and Gas Drilling

A prominent offshore drilling contractor in the North Sea used real-time monitoring systems and decision support tools to improve drilling performance and safety. The contractor reduced drilling mishaps significantly and improved overall operating efficiency by discovering downhole problems quickly and taking appropriate action.

An offshore drilling operator in the Gulf of Mexico used real-time monitoring systems and decision support tools to improve drilling performance and cut down on unproductive time. As a result, the operator was able to save money while also increasing drilling efficiency.

In the Permian Basin, a shale gas producer used real-time monitoring technologies to improve wellbore stability and reduce drilling fluid losses. By leveraging decision support tools to analyze drilling data and adjust parameters in real-time, the producer minimized wellbore instability issues and achieved higher drilling success rates.

Conclusion

Real-time monitoring systems and decision support tools have become indispensable assets in modern oil and gas drilling operations, enabling operators to optimize performance, enhance safety, and reduce costs. By harnessing the power of real-time data analytics and advanced decision support capabilities, drilling operators can navigate the complexities of drilling operations with greater confidence and efficiency.