How Digital Twins Work for Optimizing Oil Production

In the oil and gas industry, digital transformation technology is increasingly used to improve efficiency, reduce costs and optimize production. Digital twins technology has become an innovative force, providing real-time visualization, analysis and optimization of complex oil production systems. Digital twins are dynamic virtual model that reflects the physical behaviour of processes, assets or even entire production systems, by continuously integrating real-world data. When applied to oil production, it can create new opportunities for safety, efficiency and profitability.

What are Digital Twins in Oil Production

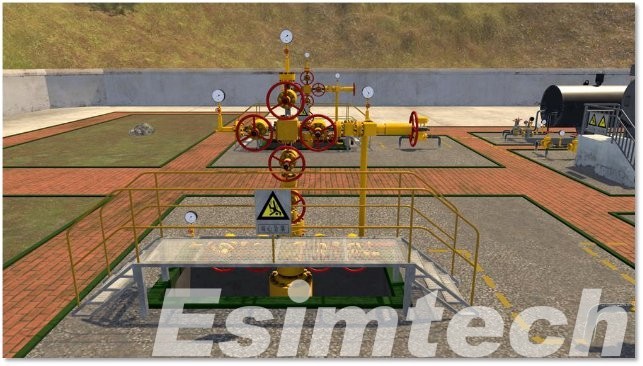

Digital twins in oil production are sophisticated computer models of pipelines, wells surface facilities, wells, and reservoirs that are constantly updated by incorporating sensor and operational information. The twins represent the physical system’s performance in various operating conditions, forecast future outcomes and offer the ability to make decisions for operators and engineers.

A digital twin could be anything from a single-well model to a complete model of the entire field. Through the combination of information from IoT devices as well as machine learning algorithms and physics-based simulations twins develop alongside their physical counterparts.

The Working Process of Digital Twins in Oil Production

The working process of digital twins involved in oil production has several stages, ranging starting with data acquisition to predictive analysis, each is crucial in providing operational intelligence.

1. Data Acquiring via Physical Assets

The initial step of the process of creating a digital twin is to capture real-time information from equipment in the oilfield. Sensors on production rigs, drilling wells, separators and compressors gather data on variables like pressure, temperature, flow rates and vibration as well as chemical composition. They are connected through industrial IoT networks or SCADA systems to guarantee uninterrupted data transmission.

Live data provide the fundamental input to the digital twin and reflects the present operational status for the actual system. High-frequency and accurate data acquisition is crucial to ensure that the digital twin is synchronized to the actual world.

2. Data Integration and Preprocessing

After the sensor data is gathered the data is processed and integration into centralized platforms for data, usually cloud-based. Data cleaning and filtering, normalization and tagging are processes that are employed to remove inconsistencies, noise and gaps. The objective is to produce high-quality data that is suitable for use for analytical modeling and simulation.

This data processed is coupled with historical operational records maintenance logs, operational records, and external inputs such as meteorological surveys or weather forecasts to improve the twin’s knowledge base.

3. Model Building and Calibration

At this point there are physics-based models as well as statistical models and AI algorithms are employed to build a virtual model of the production process. The models are calibrated with historical and real-time data to accurately represent the physical behavior of components such as reservoirs tubing pumps, separators and other components.

For instance the reservoir model could represent multiphase flow of fluid and pressure fluctuations over time, whereas an equipment model could simulate the behavior of fatigue or thermal efficiency. Calibration makes sure that the model is in line with the real system’s performance under various conditions.

4. Real-Time Synchronization and Simulation

Since the digital twin is active, it continues to ingest new data in order to stay in tune with its physical counterpart. Any changes, such as an increase in pressure in the wellbore, or a sudden decrease in pump output is immediately recorded in the digital twin’s status.

This synchronization allows dynamic oil and gas production simulation under a variety of operating conditions. Engineers can make operational adjustments made in the digital model — such as altering the rate of injection, altering valve settings or rerouting flow–before putting them into an actual environment thus reducing the risk of failure and improving the ability to make decisions.

5. Predictive Analytics and Diagnostics

The digital twin employs advanced algorithms and machine learning to identify patterns and predict the future of events. When it examines variations from typical operating parameters, the software can identify problems with equipment and production slowdowns as well as anomalies in reservoirs before they happen.

In the case of example, if a twin is able to detect an unusual frequency of the compressor, it will forecast future performance and suggest preventive maintenance. In the management of reservoirs it will be able to forecast how the withdrawal of fluids will affect the factors that affect recovery in the long run, which will allow for better long-term planning.

6. Optimization and Decision Support

Digital twins function as a decision-support system by comparing current operations to performance benchmarks. It detects bottlenecks, inefficiencies and potential to improve, and provides concrete recommendations to improve production, reduce energy usage or increase security.

In certain advanced configurations where the digital twin is connected to control systems that allow closed-loop optimization. This allows for automatic adjustments, like changing choke valves’ settings or the speed of pumps, based on actual conditions and model feedback, with no the need for manual intervention.

7. Feedback Loop and Continuous Learning

Digital twins don’t stay static, they develop. The system constantly learns from the latest data, user choices, and results which improves its accuracy in predictive modeling and accuracy as time passes. As new data is collected it is calibrated and improves its models in a self-improving feedback loop.

The flexibility of digital twins makes them the ideal choice for managing the complexity and variety of production environments for oil.

Key Benefits of Digital Twins in Oil Production

Enhanced Operational Efficiency

Digital twins let producers simulate the real-time condition of pumps, wells, compressors, as well as other crucial assets. By analysing and visualizing the production data using virtual models, operators are able to detect inefficiencies, make adjustments, and then implement the most optimal configurations, all without disrupting the physical operation. This can lead to higher efficiency and uptime.

Predictive Maintenance and Reduced Downtime

Instead of relying only on reactive or routine maintenance methods, the digital twins are able to support proactive maintenance strategies. They constantly monitor health indicators, identify unusual behavior patterns and anticipate potential failures. This information helps to plan quick intervention, decreases the amount of downtime that is unplanned, and increases the lifespan of assets that are critical to.

Improved Reservoir Management

In operations upstream, digital twins combine seismic, geological, and production data in real-time to better reservoir simulation. This can help optimize the placement of wells, improve recovery strategies and determine the performance of reservoirs over time. In the end, it results in more efficient recovery and greater utilization of resources.

Safer Operations

With emergency training simulations which can model risky scenarios, like equipment malfunctions or blowouts, digital models allow the assessment of risk and emergency planning. Operators can experiment and refine safety procedures through a virtual simulation which reduces human error while improving the response strategy on site. This improves safety and regulatory compliance.

Cost Optimization

Digital twins cut down on operational expenses through improved planning, efficient utilization of assets and reduced downtime. By avoiding the need for intervention and allowing virtual testing of changes to processes businesses save time and money. The improved efficiency of processes and equipment helps reduce production costs overall.

Real-Time Decision Support

Digital twins give engineers and operators with instant insight and actionable information. Through dashboards and simulations for oil and gas operations, decision makers can take action quickly and with confidence. The ability to simulate “what-if” scenarios and evaluate various strategies improves decision-making processes and leads to better results.

Seamless Integration Across Lifecycle

From completions and drilling to decommissioning and production, digital twins help to improve the efficiency throughout the lifecycle of an asset. It doesn’t matter if it’s real-time optimization of drilling or assessing the performance of assets at the end of their life Digital twins offer an unifying framework for operational quality.

Sustainability and Emissions Control

As industries strive to reduce carbon emissions digital twins assist in monitoring and improve energy usage as well as emissions and waste. They help simulate the environmental impacts of their operations, which allows manufacturers to use more sustainable practices, without losing efficiency.

Challenges and Future Trends in Digital Twins for Optimizing Oil Production

This chart provides a clear overview of the obstacles the industry faces and innovative directions that will shape the future of digital twins in oil production optimization.

| Challenges | Description | Future Solutions |

| Data Integration Issues | It is difficult to harmonize data from various formats, sources, and older systems. | A rise in standardization of platforms that connect and process real-time data from a variety of sources. |

| High Implementation Costs | The initial set-up of digital twins, comprising sensors, software and modeling, require substantial investment. | Cloud-based digital twin solutions will lower costs and provide flexible solutions. |

| Cybersecurity Risks | Connectivity increases, which makes us more vulnerable to cyberattacks. | AI-driven threat detection and more robust encryption protocols will help protect two environments. |

| Limited Skilled Workforce | There is a shortage of experts in domain expertise and digital technologies. | Training programs and AI-aided tools will aid operators by providing intuitive dual interfaces. |

| Model Accuracy and Reliability | Models that are inaccurate or out of date can cause poor decision-making. | Machine learning-powered models constantly improve their accuracy as time passes. |

| Resistance to Digital Transformation | The inertia of organizational and cultural culture may make it difficult to adopt. | The focus is on transformation driven by leadership and digital-first strategies in organizations. |

| Real-Time Processing Limitations in Remote Locations | The high latency of data and the limited connectivity in remote or offshore fields present operational challenges. | Edge technology and mobile 5G devices will improve the responsiveness of remote operations in real time. |

| Complexity in Modeling Subsurface Reservoirs | Modelling reservoirs that are deep and heterogeneous is still a technical challenge. | The integration of models that are based on physics and AI can enhance the understanding of complex reservoir behaviors. |

Final Thoughts

Digital twins are revolutionizing oil production, making it possible to monitor in real-time, predictive analytics and optimized operations. Through bridging the digital and physical realms, they allow for proactive operations, improve the utilization of resources and mitigate risks. As the technology continues to advance, digital twins will be an essential tool for achieving smarter, cleaner and more profitable oil production.