Snubbing vs. Coiled Tubing: Which is More Efficient for Well Intervention

Well intervention is a key procedure in the oil and gas industry since it allows operators to maintain, repair, or enhance production economically and without expensive workovers. Snubbing and coiled tubing are two of the most common methods used for well intervention. Now, the question is. Which is more efficient?

This is the question we seek to answer with this article. Snubbing and coiled tubing are compared here, with emphasis on their differences and their respective applications in well intervention.

What is Snubbing and Coiled Tubing in Oil and Gas

In oil and gas operations, well integrity and optimizing production often requires specialized intervention techniques. Two of the most common approaches are coiled tubing and snubbing. While both strategies are meant to service and access live wells, they employ completely different equipment and operational philosophies, albeit with the same end goals.

Coiled Tubing

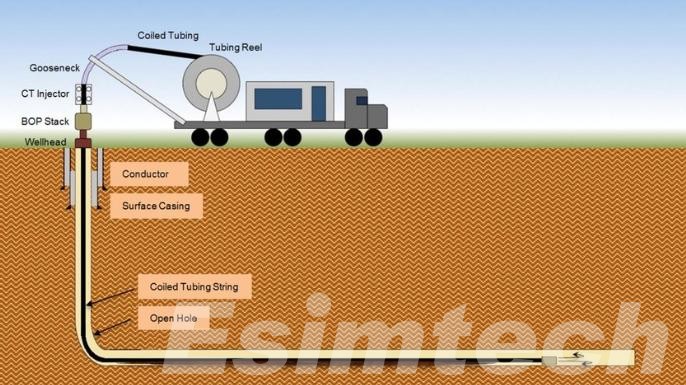

Coiled Tubing (CT) refers to a continuous length of a flexible steel CT pipe which is produced in a length of 15,000 feet and is coiled in a reel. The diameter of this steel CT pipe ranges from ¾ inches to 4 ½ inches. The range of sizes in CT tubing allows for high customization and efficiency whenever there is a need for oil wells. The coiled string is inserted in wells using injector heads, eliminating the need for jointing. The key benefits CT includes:

- Underbalanced Operations: CT allows for circulation of fluid which allows for energy and pressure balance, therefore, letting one conduct work in wells with high pressure without damaging the reservoir.

- Speed and Efficiency: CT increases overall efficiency as there is no need for threaded connection, so there is fast rigging along with trip and shut down time.

- Versatility: CT is extremely versatile and allows for a wide range of tasks from reservoir and oil well clean up to logging and light drilling, producing even sophisticated tasks like vertical re-entries and shallow wells.

- Horizontal Well Capability: The coiled tubing flexibility and the custom features it has with the reel enable perfect maneuvering and positioning of tools, enabling the coiled tubing to assist in continuously drilling forward along the horizontal sections of the well.

CT’s applicability and cost-effectiveness for well intervention have further improved in recent years due to the improvements in tubing metallurgy, sophisticated injector designs, and even the integrated downhole tools developed in the past decade.

Snubbing

Snubbing, or hydraulic workover under pressure, is a technique for running and retrieving pipe into live wells that cannot be killed due to high reservoir pressure or other control dilemmas. A “snubbing” unit uses hydraulic cylinders to “snub” or push jointed pipe into the well, overcoming the formation’s back-pressure. Critical characteristics include:

- Maintaining well control: Snubbing units are designed to encompass sustained control of pressure that will try to push the pipe out of the hole, which is critical for dealing with pressure kicks or equipment malfunctions at the wellhead.

- Jointed pipe operations: Unlike CT, snubbing does not have a restriction to standard tubing or drill pipe. This allows for heavier weight-on-bit and more robust fishing tools when required.

- Underbalanced drilling: Though snubbing is not the quickest method for tripping pipe, it is ideal for underbalanced drilling, allowing for interventions that don’t require the well to be killed, nor reservoir properties to be compromised.

- Cost and speed comments: In many scenarios, the lower cost of snubbing units has made them a replacement for higher cost workover rigs. In other situations, coiled tubing is a faster method than snubbing due to the time it takes to connect and disconnect joints.

Both snubbing and coiled tubing techniques allow for live-well interventions; however, both have distinct advantages that suit them to different operational challenges. Coiled tubing is ideal for tasks that require fast deployment, continuous circulation, and for horizontal distances. On the other hand, snubbing is more advantageous in high-pressure situations where dynamic well control with jointed pipe is crucial. Knowledge of these differences allows operators to choose the most efficient and cost-effective method for their interventions.

Key Differences: Snubbing vs. Coiled Tubing

Though both coiled tubing and snubbing methods use live well interventions, they have unique differences in design, operation and capability, and how they are applied in the field. Grasping these differences is very critical in selecting the best fit method in regard to the well conditions and intervention objectives.

Operational Overview

The use of coiled tubing incorporates rapid, flexible, and continuous interventions to a small diameter pipe reel. Other than in cleanouts, coiled tubing is applied in acidizing, nitrogen lifting, and other light interventions, particularly within horizontal wellbores.

Snubbing operates differently. It captures the action of the pushing or pulling of a jointed pipe into the well under pressure. It is primarily applicable at high pressures and for heavy pipe operations like fishing, completions, or any other work that require a high weight-on-bit.

Comparative Summary

| Category | Coiled Tubing | Snubbing |

| Pipe Type | Continuous, flexible coiled pipe | Rigid, jointed pipe |

| Well Pressure | Operates under pressure, often requires well kill for tool changes | Maintains full well control under pressure throughout |

| Speed | Faster rig-up and tripping speeds | Slower due to making/breaking connections |

| Directional Capability | Highly effective in horizontal or deviated wells | Less flexible in horizontals |

| Weight-on-Bit | Limited due to flexible pipe | High, supports heavier mechanical operations |

| Tool Deployment | Tools deployed through injector head; limited by tubing ID | Larger tool sizes possible; deployed with jointed pipe |

| Common Uses | Cleanouts, acidizing, logging, nitrogen lifting | Fishing, completions, pipe recovery, heavy-duty workovers |

| Cost Considerations | Lower for light operations; efficient for short durations | Higher for simple jobs; cost-effective for complex workovers |

Essentially, coiled tubing works best for quick, light-duty interventions, particularly in circumstances where agility and rapid response are paramount. Snubbing is most suitable for circumstances where the well cannot be killed, and significant mechanical work or stringent pressure control is needed. Each different approach has its advantages and disadvantages, balanced between Workscope and Budget.

Which is More Efficient for Well Intervention?

Well intervention efficiency differs from one well to another. Each well has its own distinct requirements. For example, coiled tubing makes responding to routine jobs like cleanouts, acidizing, and nitrogen lifts very easy because of its quick turnaround and efficiency. Cut and cover technique has its advantages, especially in horizontal or highly deviated wells. The continuously flexible pipe makes tool deployment very easy and quick. This reduces non-productive time and cuts operating costs, especially for short-term jobs.

Snubbing, however, excels when heavy mechanical loads and/or high pressures are involved. Unlike other methods, snubbing fully maintains well control, so the well doesn’t have to be killed. This makes snubbing very cost effective because it avoids the need for kill fluids and costs from pressure fluctuation. This method can Jointed pipe can be used, which increases cost-effectiveness since greater weight-on-bit, and larger fishing and completion tools can be used. Snubbing has longer rig-up times, but the cost-effectiveness for complex, high-pressure jobs makes it worth it.

Well conditions and the scope of the job define the most cost-effective method to be used.

- For light-to-medium interventions in live or deviated wells where speed and flexibility are paramount, coiled tubing maximizes efficiency.

- For heavy-duty operations under high pressure—such as fishing, installation of heavy hardware, or underbalanced drilling—snubbing offers superior safety and control, yielding better cost efficiency for extended, complex campaigns.

Evaluating the pressure requirements, complexity of the intervention, and the amount of allowable downtime helps the operators choose the method that is most performance and budget-efficient.

Both coiled tubing and snubbing have unique strengths in well intervention. The best choice is based on such considerations as work nature, pressure, and well depth. For high-pressure and high-risk wells, snubbing is safer and more effective. For routine maintenance and faster operations, coiled tubing is more efficient and cost-effective.

By understanding the strengths of each method, operators are able to maximize well intervention strategies to ensure optimum productivity and safety.