The Crucial Role of Cementing in Drilling

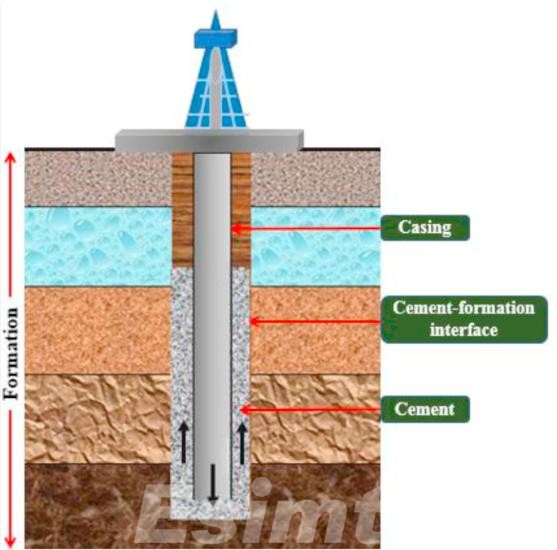

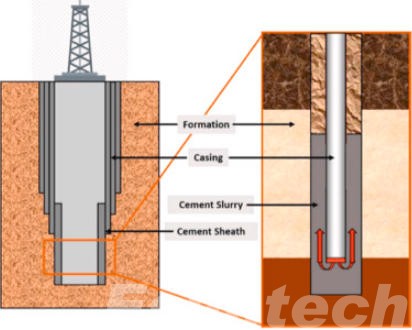

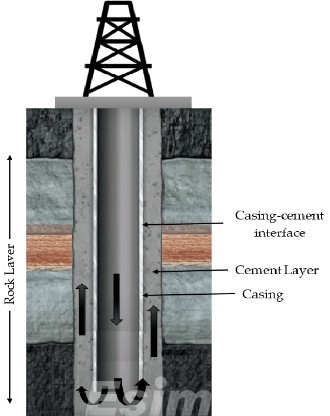

Cementing is one of the most important operations during the drilling of oil and gas wells. It maintains the integrity, safety, and efficiency of the wells throughout their operational life. Cementing is performed by positioning the cement slurry between the casing and the wellbore, which secures the casing, prevents fluid migration, and protects the well.

Key Functions of Cementing in Drilling

Cementing is a vital step in the drilling process as it establishes the mechanical well stability and preserves the subsurface from unwanted pressures, and stops fluids from migrating through different subsurface zones. Understanding the key functions of cementing allows engineers to design wells that are dependable saving them from costly production failures.

1. Providing Zonal Isolation

The most important function of cementing is zonal isolation. It means the control of fluids between different subsurface formations. If not adequately isolated, gas or water can flow into oil zones or freshwater aquifers and cause production inefficiencies and posing environmental risks. Cement achieves this by ensuring the targeted zones remain closed, thus safe and efficient hydrocarbon extraction is possible from the desired reservoir without pressure loss or contamination.

2. Supporting and Securing the Casing

When it comes to providing the proper support for the casing string, cementing is crucial. Once it is set and hardened, it keeps the casing cemented and fixed in position, preventing it from casing deformation due to the pressure on the casing in the hole. This makes sure the wellbore remains aligned and the casing formation and pressure. If the cement support was insufficient, the casing would buckle, collapse, shift, or lose structural integrity, which poses a great risk to the entire well.

3. Protecting the Casing from Corrosion

Cementing also serves the important function of covering the steel casing and preventing it from coming into formation fluid corrosion. As long as the cement sheath is well fitted and maintains closure around the casing cement, it will prevent the formation fluid brine, hydrogen sulfide, and carbon dioxide. This also helps protect the casing from leaks and saves the casing from losing corrosion and sharp closure.

4. Preventing Fluid Migration and Formation Damage

Cement prevents fluid from leaking between formations and stops formation damage since it seals porous zones and fractures in the borehole wall. If fluid movements are not controlled, they can cause formation damage, pressure imbalances, and even issues with well control. When a cement sheath is properly placed, it creates a strong, impermeable barrier that blocks unwanted fluid pathways. Containment of fluids is even more critical in high-pressure formations. Rapid gas or fluid migration in these formations can lead to blowouts and other extreme safety situations.

5. Providing Wellbore Stability

While drilling and production are in progress, the wellbore is subject to a number of different pressures, and these can cause the well to become unstable. Cementing helps strengthen the well structure and stabilizes weak or unconsolidated formations to stop them from collapsing or caving in. In high-pressure and high-temperature wells, cement also helps pour more even layers, and thus, even more, stress is distributed along the casing. This is necessary to maintain the mechanical integrity of the borehole and reliable operational performance over time.

6. Facilitating Future Operations

During the initial phases of drilling, cementing is critical, but it also continues to be pivotal for future activities with the well. An adequately cemented well makes it possible to perforate, stimulate, and produce the well without risking the integrity of the well. It also serves as a solid and safe base for setting packers to complete the well. In the case of well abandonment, cement plugs sealed and bonded the well to eliminate long-term environmental liabilities.

7. Ensuring Environmental Protection and Regulatory Compliance

Proper cementing is essential for environmental protection and compliance with regulatory requirements. Cementing keeps freshwater aquifers safe from contamination by sealing them off from hydrocarbon-bearing zones. Numerous regulatory agencies demand proof of correct and complete cement placement before starting well production, ensuring wells are constructed in a manner that minimizes environmental consequences. Thus, in modern drilling operations, cementing fulfills an essential legal and ethical requirement and an engineering necessity.

Types of Cementing Operations in Drilling

| Type of Cementing Operation | Description | Main Objectives | Typical Applications |

| Primary Cementing | The initial placement of cement between the casing and the borehole wall after casing installation. | To provide zonal isolation, support the casing, and prevent fluid migration. | Used in every well during initial completion to secure casing strings. |

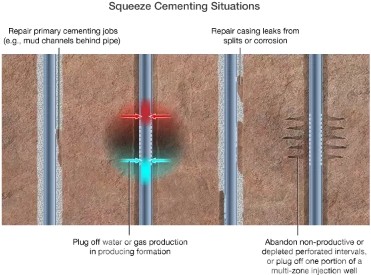

| Remedial Cementing | Performed after primary cementing to correct problems such as leaks or poor bonding. | To repair or improve the integrity of the cement sheath and restore zonal isolation. | Applied when there are casing leaks, channeling, or incomplete cement coverage. |

| Squeeze Cementing | A type of remedial cementing where cement is forced under pressure into specific zones or leaks. | To seal off channels, fractures, or perforations in the casing or formation. | Used to stop fluid migration, repair casing leaks, or isolate unwanted zones. |

| Plug Cementing | Involves placing a cement plug inside the casing or wellbore at a specific depth. | To seal off a portion of the well, provide a base for sidetracking, or abandon a section. | Commonly used for temporary or permanent well abandonment, sidetracking, or zone isolation. |

| Secondary Cementing | Conducted after primary cementing to address operational issues or reinforce well integrity. | To enhance well stability, seal off problem zones, or ensure long-term isolation. | Used in high-pressure wells or where additional support is needed after initial cementing. |

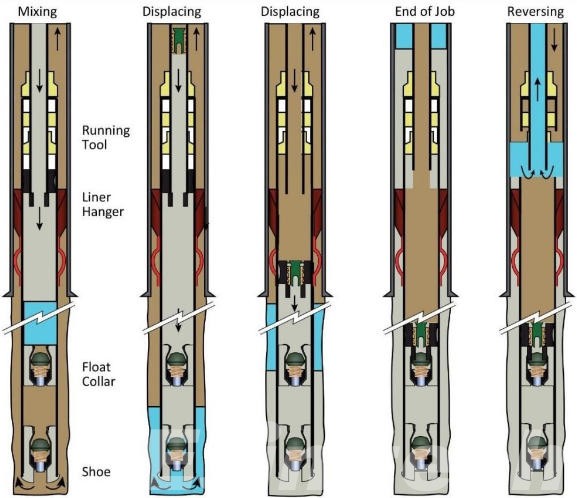

| Liner Cementing | Cementing a liner string (a shorter casing) instead of a full casing string. | To provide zonal isolation for a specific section while saving cost and space. | Applied in deep wells or when drilling through multiple formations requiring selective casing. |

| Stage Cementing | Performed in multiple stages using special tools to cement different intervals of the wellbore. | To achieve effective cement placement in long casing strings or challenging formations. | Used in deep or deviated wells where single-stage cementing may not be effective. |

Cementing Materials and Additives in Drilling Operations

During drilling operations, cementing materials and additives are vital for determining the quality, durability, and effectiveness of well cementing and must be incorporated. Cement slurry must be designed to be able to withstand a variety of pressure, temperature, and varying formations conditions that will be encountered downhole.

- Portland Cement

Portland cement is the primary component of all cementing operations. It is a hydraulic cement that hardens upon the addition of water. It is made up of calcium silicates, aluminates, ferrites that will form a solid structure through hydration. Different classes of Portland cement is determined by the depth and temperature of the well. For example, Class A and B cements can be used for shallow, low-pressure wells, and Classes D, E, and F cements are for high-pressure, high-temperature (HPHT) wells. Choosing the right class of cement helps to ensure that the cement will maintain integrity at all the required conditions of the well.

- Accelerators

Accelerators are additives that reduce the amount of time cement slurry takes to set. They are valuable additions to shallow wells or areas with low temperatures, since those conditions tend to slow down the cementing process. They reduce the time of cementing operations, and the time until the next drilling or production phase. Common accelerators are calcium chloride (CaCl₂) and sodium chloride (NaCl). It is important to control the quantity of accelerators added to the cement, as cement that hardens too quickly may be weaker.

- Retarders

Retarders slow down the hardening process so during periods of heavy placement the cement does not harden too early. This is important in hot weather or in deep wells in order to allow the cement to reach the desired depth as a pumpable slurry. Common retarders are lignosulfonates and cellulose derivatives and organic acids. In high temperatures and extended circulation periods, these additives aid in the control of the cementing process.

- Weighting Agents

Weighting agents are used to change the density of the cement slurry. When working in high-pressure formations, increasing the density of the cement slurry helps control formation pressure so the formation won’t blowout. Barite (BaSO₄) and hematite (Fe₂O₃) are the most common materials used as weighting agents. In weak or fractured formations, pressures are high enough to cause lost circulation which is why it is important to reduce the density of the cement. This can be achieved by using bentonite, perlite, or microspheres.

- Fluid Loss Control Agents

Fluid loss during cement placement can lead to porous formations which in turn can weaken the cement. Fluid loss control agents are used to keep the proper water-to-cement ratio and reduce excessive water loss. This allows the cement to set with the required strength and permeability. Common fluid loss control agents are cellulose derived polymers and synthetic polymers. These agents enhance the performance of the cement slurry in varying formation conditions.

- Dispersants

Dispersants are an important additive for decreasing the viscosity of cement slurries, improving the flow and pumpability, and keeping the solids suspended. They facilitate the uniform mixing of slurries during the pumping process. This ensures better displacement of drilling mud and more efficient cement placement along the casing. Common dispersants include sulfonated naphthalene formaldehyde condensates and other water reducing agents.

- Expansion Agents

Expansion agents are added to cement to overcome the natural slight shrinkage that occurs during hydration. This shrinkage can create micro channels and gaps between the casing and cement, resulting in reduced bond tightness and ineffective zonal isolation. Calcium oxide and magnesium oxide are example materials that can induce slight controlled expansions during the curing process.

- Pozzolanic and Silica-Based Additives

Pozzolanic materials like fly ash, silica fume, and metakaolin improve the performance of cement as well as the strength, and the cement becomes less permeable and more resistant to chemical attacks. These attributes are essential for high temperature wells. They help maintain the required long-term structural integrity.

- Specialty Additives

Every well has its own challenges and needs specialty additives to work with. For example, latex polymers lessen permeability and increase elasticity while anti-gas migration additives stop gas from migrating through unset cement. In the presence of numerous corrosive elements, the addition of inhibitors will enhance the cement’s chemical resistance. More recently, additives with nanotechnology features have been introduced. These additives cement the sheath and strengthen the bond, making it self-healing and more advanced.

A Step-by-Step Overview of Cementing Process in Drilling

| Process Stage | Description | Key Objectives |

| Step 1. Planning and Design | Engineers analyze well data, formation properties, and pressures to design the cement slurry and placement plan. Cement type, additives, and densities are selected based on downhole conditions. | Ensure the cement system is tailored for well depth, temperature, and pressure; prevent future integrity issues. |

| Step 2. Pre-Job Preparation and Rig-Up | All cementing equipment such as pumps, mixers, and lines are inspected and tested. Materials are prepared, and safety checks are completed. | Verify operational readiness, ensure safety compliance, and prepare for smooth cementing execution. |

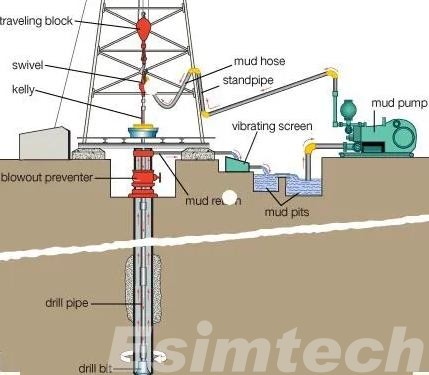

| Step 3. Conditioning the Wellbore | The drilling mud is circulated and conditioned to remove cuttings and stabilize the wellbore. Spacers and preflushes are pumped to improve mud displacement. | Enhance cement bonding by minimizing mud contamination and ensuring a clean borehole. |

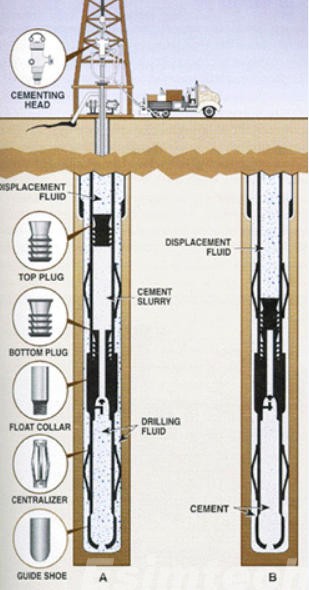

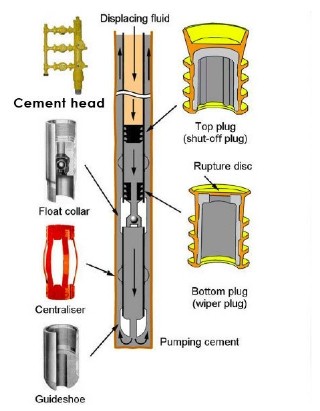

| Step 4. Running the Casing | The casing string is lowered into the wellbore to the desired depth. Float collars, centralizers, and other equipment are installed. | Position the casing accurately and maintain centralization for uniform cement placement. |

| Step 5. Mixing the Cement Slurry | The cement and additives are mixed with water at the surface to form a uniform slurry with the desired density and rheology. | Achieve consistent slurry properties for predictable flow and setting behavior. |

| Step 6. Pumping the Cement | The cement slurry is pumped down the casing, displacing drilling mud. It exits the casing shoe and flows upward into the annular space. | Place cement evenly in the annulus to provide zonal isolation and casing support. |

| Step 7. Displacement and Plug Operation | Bottom and top plugs are used to separate fluids. The top plug indicates cement placement completion when it lands on the float collar. | Ensure complete displacement of mud and accurate cement placement without contamination. |

| Step 8. Waiting on Cement (WOC) | After placement, the cement is allowed to set and harden under static conditions for a specified period. | Develop sufficient compressive strength and bond integrity before resuming drilling or completion. |

| Step 9. Evaluation of Cement Job | Tools such as cement bond logs (CBL) or ultrasonic imaging are used to evaluate cement coverage and quality. | Confirm zonal isolation, casing support, and proper bonding between cement, casing, and formation. |

Challenges and Potential Solutions in Cementing Operations for Drilling

| Challenge | Description | Impact on Cementing Quality | Possible Mitigation Measures |

| Poor Mud Removal | Incomplete displacement of drilling mud from the wellbore and casing wall due to improper circulation or mud properties. | Leads to weak bonding between cement and formation, causing channeling or fluid migration. | Use compatible spacers and flushes, improve circulation rate, and optimize centralizer placement. |

| Lost Circulation | Occurs when cement slurry or drilling fluids are lost into fractured or weak formations. | Results in incomplete cement fill and lack of zonal isolation in affected sections. | Use lightweight or lost-circulation-resistant cement, pre-treat formations with sealing materials, and control pump pressures. |

| Gas or Fluid Migration | Movement of gas or fluids through unset cement before it hardens, often in high-pressure formations. | Creates micro-channels, compromising zonal isolation and potentially leading to gas leaks. | Apply anti-gas migration additives, maintain hydrostatic pressure, and monitor transition time during setting. |

| Improper Slurry Design | Incorrect cement formulation for temperature, pressure, or well depth. | Causes poor set strength, shrinkage, or excessive thickening time, reducing long-term integrity. | Conduct lab testing, use temperature- and pressure-appropriate additives, and simulate downhole conditions. |

| Inadequate Centralization | Poor placement of centralizers along the casing causes uneven annular spaces. | Results in uneven cement distribution and potential weak spots. | Ensure correct centralizer type and spacing based on well geometry and inclination. |

| Temperature and Pressure Variations | Significant changes during cementing can alter slurry rheology and setting behavior. | Affects cement strength and placement efficiency, especially in deep or HPHT wells. | Use temperature-stable retarders or accelerators and model downhole temperature profiles. |

| Channeling and Contamination | Mixing of cement with drilling mud or spacer due to insufficient fluid separation. | Leads to contaminated slurry with low strength and poor bonding. | Employ proper plug sequences, maintain flow consistency, and monitor displacement volumes. |

| Narrow or Irregular Wellbore Geometry | Washouts, tight spots, or irregular borehole shapes hinder uniform cement flow. | Results in partial cement coverage and trapped mud pockets. | Use caliper logs to assess borehole shape, optimize slurry volume, and adjust pumping rates. |

| Equipment Malfunction | Failures in pumps, lines, or mixing units during cementing. | Causes job interruption, poor displacement, and inconsistent cement placement. | Perform pre-job equipment checks, have backup systems ready, and follow maintenance schedules. |

| Inadequate Job Evaluation | Insufficient post-cementing assessment using logging tools or pressure tests. | Conceals poor cement bonding or incomplete isolation, leading to long-term issues. | Conduct cement bond logs, temperature surveys, and remedial cementing if needed. |

Innovations in Cementing Technology for Complex Drilling Environments

Technical limitations of traditional cementing styles have made it difficult to meet performance needs as drilling goes deeper and hotter and encounters complex geological layers. In response to these challenges, innovative technologies in cementing have emerged in the oil and gas sector. These innovations increase reliability, adaptability, and even the eco-friendliness of cementing processes.

- Advanced Cement Formulations

New engineered cementing systems are made for unconventional drilling and HPHT environments. For example, cements with nanotechnology incorporate cementing and sealing layers with ultra high strength concrete and reduce the sealing layers permeability. During thermal cycling, the microcracking and surface cracking are kept to a minimum. In addition, the flexible self-healing cement systems have been advanced to allow the material to extend well integrity by sealing micro-annuli or fractures that form after setting.

- Lightweight and Foam Cement Systems

Lightweight and foam cement systems are gaining popularity in formations prone to lost circulation. To reduce cement density and maintain adequate compressive strength, cementing systems incorporate nitrogen or microspheres. The reduction in hydrostatic pressure helps to avoid formation breakdown and loss of circulation, particularly in depleted and unconsolidated zones. These cementing systems also have tailored rheological properties that assist placement in intricate well designs.

- Real-Time Monitoring and Automation in Cementing Operations

The application of new digital technologies to cementing has made it more automated and data-driven. Slurry density, flow rate, and displacement efficiency are just some of the parameters that automated systems use to monitor performance during the pumping stages. Real-time systems monitor performance, and automated systems change the parameters of mixing and pumping to keep performance within defined limits. Predictive analytics and digital twins help reduce the chances of cement failure or poor zonal isolation.

- Environmentally Friendly Cement Alternatives

As the world becomes more sustainable, scientists are trying to make low-carbon cement options to make drilling operations more eco-friendly. Take geopolymer cements, for example. Instead of using the traditional Portland cement clinker, geopolymer flies uses by-products like fly ash or slag. This drastically reduces CO₂ emissions. Plus, the slag by-products have better chemical resistance and thermal stability, making them very useful for formations that are extremely corrosive or have high temperatures.

- Expandable and Elastic Cement Systems for Dynamic Wells

Deepwater or geothermal wells are subject to extreme mechanical stresses and traditional, rigid cement can crack under strain. Expandable and elastic cement systems are designed to adjust to casing movement, thermal expansion, and formation shifts while still keeping a perfect seal. These systems are capable, as promised, of maintaining long-term zonal isolation even with extreme pressure and temperature changes.

- Advanced Displacement Modeling and Simulation Tools

Cement placement is a complex hydraulic process that depends on multiple variables, including mud rheology, annular geometry, and flow dynamics.

This chart provides advanced simulation technologies used for cement placement in drilling operations

| Simulation Type | Description | Key Parameters Modeled | Benefits |

| 1. Hydraulic Simulation Models | Simulate the flow of fluids in the annulus during cement placement to ensure complete mud displacement and prevent channeling. | Flow rate, annular pressure, mud and cement rheology, casing eccentricity. | Improves cement placement efficiency and reduces risk of fluid channeling. |

| 2. Displacement Efficiency Simulation | Drilling simulation systems analyzes the interface behavior between drilling mud, spacer, and cement slurry to evaluate displacement quality. | Fluid densities, viscosities, contact angles, flow regimes. | Ensures better mud removal and minimizes contamination at the cement interface. |

| 3. Temperature and Pressure Profile Simulation | Models temperature and pressure changes during cement pumping and setting to predict slurry performance under downhole conditions. | Circulation rate, formation temperature, bottomhole pressure, cement thickening time. | Prevents premature setting and ensures accurate slurry design for HPHT environments. |

| 4. 3D Annular Flow Simulation | Uses computational fluid dynamics (CFD) to visualize complex flow patterns in irregular wellbores or eccentric casings. | Annular geometry, turbulence intensity, mud-cement interface behavior. | Provides high-accuracy prediction of flow behavior and aids in centralizer optimization. |

| 5. Gas Migration Simulation | Predicts potential for gas or fluid migration through unset cement by modeling pressure and gas mobility during the transition phase. | Hydrostatic pressure, gel strength development, permeability evolution. | Helps design anti-gas migration additives and timing strategies. |

| 6. Cement Strength Development Simulation | Simulates the hydration and setting behavior of cement to predict final compressive and tensile strength. | Temperature profile, curing time, slurry composition. | Ensures long-term mechanical integrity and zonal isolation performance. |

| 7. Multi-Phase Flow Simulation | Models interactions among drilling fluids, cement, and formation fluids to evaluate possible contamination and interface stability. | Fluid density differences, flow velocities, interfacial tension. | Enhances understanding of multi-fluid displacement behavior. |

| 8. Real-Time Cement Placement Simulation | Integrates live data from downhole sensors and surface equipment to update cement placement predictions during the operation. | Real-time flow rate, density, and temperature data. | Allows on-the-fly adjustments for improved job control and safety. |

- Integration of Fiber-Reinforced Cement Systems

Fiber-reinforced cement composites improve tensile strength and crack resistance by adding synthetic or metallic fibers into the slurry. This system provides valuable extra toughness, particularly useful in wells with unstable formations or high mechanical loads. the fibers improve mechanical integrity by acting as micro-reinforcements that redistribute stresses and stop cracks from spreading, helping to hold the cement sheath together.

Final Thoughts

For guaranteeing well stability, safety and environmental protection, cementing in drilling is vital. Along with new materials, digital monitoring systems and innovative engineering designs, advanced cementing technologies allow more dependable and efficient wells to be constructed in more complex geological environments.