The Importance of Well Planning in Oil and Gas Production

What is Well Planning?

Well planning is a crucial aspect of oil and gas production, involving the comprehensive design and preparation of a drilling project before any physical operations commence. It encompasses a range of activities, from geological assessments and site selection to the design of the wellbore trajectory and selection of appropriate drilling equipment. The primary objective of well planning is to optimize the drilling process, ensuring that it is safe, cost-effective, and efficient. By addressing potential challenges and uncertainties ahead of time, well planning helps to minimize risks and enhance the overall success rate of drilling operations.

What are the Benefits of Well Planning?

Thorough well planning offers a multitude of advantages for oil and gas companies:

- Increased Production: Well planning goes beyond simply hitting the reservoir. By using geological data and advanced modeling techniques, wellbore trajectories can be designed to target the most productive zones within the reservoir. This can involve maximizing the wellbore’s exposure to pay zones (sections with high oil or gas saturation) and minimizing the intersection with unproductive layers. Well planning also helps determine the optimal wellbore placement to access multiple pay zones within the reservoir or utilize enhanced oil recovery (EOR) techniques later in the well’s life.

- Reduced Costs: Well planning doesn’ t stop at finding the oil; it’s about finding it efficiently. By optimizing drilling procedures, well planning can significantly lower overall project costs. This can involve factors like selecting the most efficient drilling rig for the job, minimizing the number of wellbore directional changes, and using real-time data to avoid drilling into unexpected formations that might require specialized equipment or techniques. Well planning also helps reduce “non-productive time” – periods where drilling is halted due to unforeseen challenges.

- Enhanced Safety: A well-planned well reduces the likelihood of encountering unexpected hazards during drilling, promoting safety for personnel and the environment. Well planning incorporates data on potential formation pressures, presence of faults or unstable zones, and potential for encountering harmful substances like hydrogen sulfide. This allows engineers to design the wellbore with appropriate casing strength, blowout preventers, and mud programs to mitigate these risks.

- Improved Efficiency: Well planning streamlines the drilling process, leading to faster well completion times. By having a clear roadmap for each stage of drilling, logistics and equipment mobilization can be optimized. Well planning also facilitates proactive problem-solving, as potential issues can be anticipated and addressed before they cause delays.

- Environmental Protection: Well planning incorporates measures to prevent environmental damage during drilling. This can involve planning wellbore trajectories to avoid environmentally sensitive areas, using drilling fluids with minimal environmental impact, and having spill prevention procedures in place. Well planning also considers regulations and best practices to minimize the industry’s environmental footprint.

By reaping these benefits, well planning plays a crucial role in the economic and environmental sustainability of oil and gas production.

What is The Well Planning Process?

Geological and Geophysical Analysis

The initial phase of well planning involves a thorough analysis of geological and geophysical data to identify the best drilling locations. This step is crucial for understanding the subsurface conditions and involves several key activities:

- Seismic Surveys: High-resolution seismic surveys are conducted to create detailed images of the subsurface geology. This helps in identifying the presence of oil and gas reservoirs, faults, and other geological features.

- Rock and Fluid Properties: Core samples and well logs from existing wells are analyzed to understand the properties of the rocks and fluids in the reservoir. This information is essential for predicting how the reservoir will behave during production.

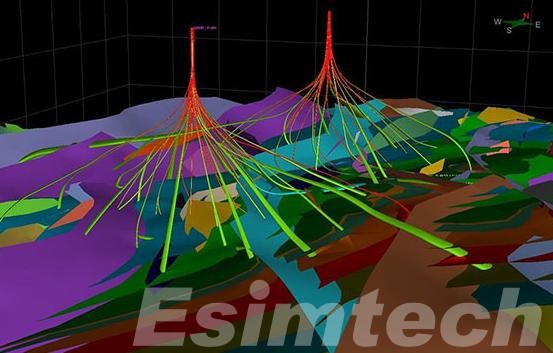

- Reservoir Modeling: Geological and petrophysical data are integrated to create a 3D model of the reservoir. This model helps in visualizing the reservoir’s structure, estimating reserves, and planning the optimal well path.

Well Design

Once the geological analysis is complete, the well design phase begins. This involves several critical decisions and designs that ensure the well is constructed to achieve its production goals safely and efficiently:

- Trajectory Planning: The well’s trajectory is planned to reach the target reservoir efficiently while avoiding geological hazards. This includes deciding between vertical, directional, or horizontal drilling based on the reservoir’s characteristics.

- Casing and Cementing Design: Appropriate casing strings are selected to stabilize the wellbore and prevent contamination of groundwater. Cementing plans are developed to secure the casing and isolate different subsurface layers.

- Drilling Fluid Selection: The choice of drilling fluid (mud) is crucial for maintaining wellbore stability, controlling pressure, and removing cuttings. The fluid’s properties are tailored to the specific conditions of the well.

Cost Estimation and Budgeting

Accurate cost estimation is essential for financial planning and project viability. This phase involves a detailed breakdown of all expected costs, including:

- Equipment and Materials: Estimating the costs of drilling rigs, casing, cement, drilling fluids, and other materials.

- Labor: Calculating the costs for the workforce required for drilling, including rig operators, engineers, geologists, and support staff.

- Logistics: Accounting for the transportation and logistics costs associated with moving equipment and personnel to the drilling site.

- Contingencies: Allocating funds for unexpected challenges, such as equipment failures or geological surprises, to ensure the project remains on budget.

Risk Assessment and Mitigation

Risk assessment is a critical part of well planning, aimed at identifying and mitigating potential hazards that could impact the drilling operation. This involves:

- Hazard Identification: Recognizing potential risks such as blowouts, equipment malfunctions, and environmental incidents.

- Risk Analysis: Assessing the likelihood and potential impact of each identified risk. This includes analyzing historical data, industry benchmarks, and site-specific factors.

- Mitigation Strategies: Developing plans to mitigate identified risks. This could include implementing blowout preventers, designing redundant safety systems, and preparing emergency response plans.

Regulatory Approvals

Compliance with regulatory requirements is mandatory in the oil and gas industry. The regulatory approval phase ensures that the planned operations adhere to all legal standards and environmental guidelines:

- Permitting: Obtaining the necessary permits to drill, which may include environmental impact assessments, drilling permits, and water use permits.

- Regulatory Submissions: Submitting detailed drilling plans, environmental assessments, and safety protocols to relevant regulatory bodies for review and approval.

- Stakeholder Engagement: Engaging with local communities, governments, and other stakeholders to address concerns and secure social license to operate.

Operational Planning

The final phase of well planning is the detailed operational planning, which ensures that the drilling process is executed smoothly and efficiently:

- Scheduling: Developing a detailed schedule for drilling operations, including timelines for each phase of the project, from mobilization to completion.

- Resource Allocation: Allocating resources such as equipment, personnel, and materials to ensure that everything is available when needed.

- Logistics and Coordination: Coordinating with subcontractors, suppliers, and logistics providers to ensure timely delivery of equipment and materials. This also includes planning for the transportation and accommodation of personnel.

- Monitoring and Control: Implementing systems for real-time monitoring and control of the drilling process. This includes using data from downhole sensors, surface equipment, and drilling rigs to make informed decisions and adjustments.

Summary

Well planning is the foundation for successfully drilling oil and gas wells. By carefully planning each stage of the drilling process, oil companies can maximize production, reduce costs, ensure safety, and minimize environmental impact. Well planning is an ongoing process that requires collaboration among various disciplines to achieve optimal results.