What Do You Know about Autonomous Offshore Drilling Rigs

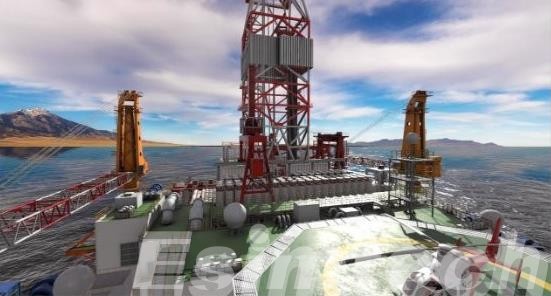

This offshore drilling industry is going through a technological transformation as autonomous technologies is redefining how energy is explored and extracted beneath the ocean floor. Autonomous offshore drilling rigs, powered by the advancements in artificial intelligence (AI), robotics and real-time data analysis, are becoming a revolutionary solution to enhance efficiency, safety and cost-effectiveness in deepwater drilling.

Why Need Autonomous Offshore Drilling Rigs

Offshore drilling platforms traditionally are complicated and labor-intensive, requiring many workers, constant surveillance, and a significant risk. However autonomous offshore drilling platforms are equipped with sophisticated control systems and machine learning algorithms that are able to complete a variety of tasks with minimal human intervention. Through reducing the need for human oversight, these offshore rigs can increase efficiency while reducing the risk of human errors.

Addressing Safety Risks in Harsh Environments

Offshore drilling rigs are conducted in the most dangerous and unpredictable locations on the planet, in depthwater drilling to Arctic conditions. These environments pose serious dangers to workers’ safety as they are exposed to extreme weather conditions, high-pressure systems and potentially hazardous substances. Through reducing the number of workers required on the job and automating risky tasks like pipe handling and inspection of equipment autonomous rigs greatly improve worker safety, and decrease the chance of accidents.

Enhancing Operational Efficiency and Precision

Offshore drilling is extremely complicated and time-sensitive. Even the smallest of errors could result in significant time-span delays as well as financial damages. Autonomous systems provide a whole new level of reliability and precision to drilling. With the help of real-time data analytics and AI-driven decision making, the rigs can be optimized for drilling parameters, cut down on the amount of time wasted, and increase the overall accuracy of drilling wellbore. In the end, production and exploration timelines are reduced, and resources are utilized more efficiently.

Reducing Costs in a Volatile Market

Oil and Gas is marked by price fluctuations and large capital expenses. Autonomous offshore drilling equipment provides the long-term benefit of cost savings in that they reduce the need for large offshore teams, and reducing downtime by implementing predictive maintenance and streamlining the operations with little intervention. Although the initial investment into autonomy is substantial but the ROI can be realized by sustaining operational savings and a higher uptime.

Meeting Environmental and Regulatory Demands

Environmental pressures and regulations are growing in the energy sector offshore. Autonomous rigs promote environmental stewardship by reducing emissions, stopping blowouts by monitoring conditions in real-time and providing faster responses to issues that could arise. Data logging and control enhancements can also ensure a better conformity with international environmental laws and is becoming increasingly crucial for businesses operating in areas with fragile marine ecosystems.

Enabling Remote and Deepwater Exploration

In the wake of readily accessible reserves being exhausted, exploration is shifting into more remote and deeper waters, where traditional manned operations are more challenging and costly. Autonomous rigs are ideal for these difficult environments since they can work independently and adjust to the changing environment and operate for longer periods with no human involvement. This opens up the possibilities of exploration, and permits energy companies to tap previously untapped sources.

Driving Digital Transformation in the Energy Sector

Automated offshore drilling equipment are an essential part of the wider digital revolution that is taking place within the industry of oil and gas. Through the integration of robotics, AI machine learning, as well as digital twins into these drilling rigs function as advanced platforms that gather information, process, and analyze data in a way that is more efficient than before. This change not only enhances the performance of individual drilling rigs but also improves an improved digital structure of all drilling networks.

Preparing for the Future of Energy Production

As the demand for energy in the world grows and new technologies develop and the offshore drilling industry has to adapt to stay competitive. Autonomous rigs aren’t just an answer to current problems, but serve as a basis for the future of innovation. With the increasing demand for Carbon Capture, subsea equipment or hybrid power platforms autonomy is expected to play an important role in the shaping of future offshore power systems the future.

Key Technologies Driving Autonomy in Offshore Drilling Rigs

These key technologies have revolutionized offshore exploration by transforming the rigs into self-governing, intelligent systems.

1. Artificial Intelligence and Real-Time Analytics

The basis for autonomous drilling is on artificial intelligence, as well data analysis that is real time. Drilling rigs are equipped with a myriad of sensors that collect information about temperature, pressure as well as vibration, torque, and feedback from geological sources, AI algorithms interpret this massive data stream and constantly adjust. The systems are trained to detect patterns that signal imminent wear on equipment, changes in formation or instability in the wellbore. In doing this they can allow the rig to adjust parameters such as weight on the bit and drilling speed, without any human supervision. This results in a system that is able to learn from its mistakes and gets better over time and also reduces downtime and operating costs.

2. Robotics and Automation Systems

Automated offshore rigs wouldn’t exist without the use of robotics or modern automation. Jobs that were once requiring large teams of humans, such as pipe handling, inspection of equipment and rig maintenance are now performed by robots with the highest level of precision and reliability. They’re designed to withstand the harsh marine conditions as they operate around the clock with a minimum of errors. Integration into the rig’s operations not only improves speed and reliability, but also dramatically increases safety by reducing exposure to dangerous areas for example, derricks and drilling floors.

3. Digital Twin Technology

A significant step towards reaching autonomy was the use technology known as digital twins. Digital twins are virtual replicas of the rig’s physical structure and the subsystems that are continuously updated with real-time information. Offshore operators can communicate via the virtual twin in order to simulate oil and gas operation scenarios, anticipate failures and make plans for maintenance. The digital twin can also aid in machine learning by offering an environment for testing where autonomous systems can predict outcomes and improve the precision of their decision-making without disrupting actual processes. Through its role as a bridge between digital and physical realms the digital twin can play an essential role in the process of controlling predictively and remote control of offshore drilling rigs.

4. Edge Computing

The huge amount of data produced by offshore rigs and the delay of transmitting it to central cloud servers create a unique obstacle. Edge computing addresses this issue by bringing computing closer to the source, directly to the rig. Edge devices process data in real-time autonomous control systems can react instantly in emergency circumstances, like pressure abnormalities or malfunctions in equipment. This ability to make decisions locally is essential to ensure the safety and efficiency of your equipment, particularly in remote locations in areas where connectivity is weak or not reliable.

5. Integration of Intelligent Systems

It’s not just about intelligent individual components, it demands unidirectional integration of every subsystem within an operational framework that is unifying. Modern offshore drilling rigs employ controlled systems integrated into the system that connect together information from drilling machines and power management, navigation as well as environmental monitors. They operate by using centralized interfaces, which coordinates decisions using a holistic awareness of the environment. This close integration makes sure that each action performed by the rig is part of a coordinated plan, whether it’s altering drilling parameters or initiating emergency procedures.

6. Advanced Telemetry and Monitoring Technologies

Autonomous operation is dependent on a equipment’s ability to detect and discern its surroundings in a precise manner. Advancements in telemetry and downhole monitoring have extended the scope offshore rigs to a greater extent than the surface. Instruments embedded in the borehole transmit high-resolution data about the rock’s properties as well as fluid pressures as well as borehole condition. Additionally, surface-based sensors keep track of equipment performance as well as environmental variables like the height of waves as well as wind speed and platform motion. Together, these data feed an autonomous brain, which allows it to make intelligent, precise adjustments in real-time.

Challenges and Solutions in Autonomous Offshore Drilling Rigs

| Challenge | Description | Solution |

| High Capital Investment | Autonomous systems have significant upfront expenses for devices and their integration. | The focus should be on long-term ROI gradual implementation, and co-operation with tech partners. |

| Cybersecurity Vulnerabilities | More connectivity makes rigs vulnerable to cyberattacks. | Set up secure cybersecurity protocols, ongoing monitoring and secure communications layers. |

| Technical Integration Complexity | It is difficult to integrate new autonomous technologies into existing infrastructure. | Utilize modular systems Open architecture designs along with common interfaces. |

| Limited Regulatory Frameworks | Current regulations do not completely cover the autonomous offshore activities. | Get involved with regulators in the development of new guidelines and take part in international standardization efforts. |

| Environmental Reliability | In the harsh offshore environments, it can be difficult to conduct autonomous operations. | Design rugged hardware, create redundant systems and improve environmental monitoring. |

| Data Overload and Management | The massive amount of data generated is often difficult to manage or analyze and then take action on. | Utilize edge computing to perform local processing. You can also make use of AI-driven analytics to make immediate decision-making. |

| Workforce Skill Gaps | Lack of skilled personnel to maintain and manage autonomous technology. | Develop training programs, refresh employees, and work with institutions of higher learning. |

| Ethical and Liability Concerns | Uncertainty about accountability in the event of system malfunctions or accidents. | Set out legal obligations, create security protocols, and incorporate human surveillance layers. |

Future Outlook of Autonomous Offshore Drilling Rigs

As technology advances and the industry adapts to the new safety, economic and environmental demands, the use of autonomous offshore drilling rigs is likely to grow exponentially.

- Transition to Fully Unmanned Operations

The coming decade is likely to see a gradual transition from semi-autonomous platforms to completely non-manned offshore platforms. Thanks to advances in remote-control technology, offshore platforms will be operated and controlled entirely by command centers onshore. This will not only increase security by reducing exposure of crew members for harsh environments in the marine environment, but will also cut down on the expenses that are associated with logistics offshore accommodation, as well as emergency systems.

- Intelligenter Decision-Making Using AI and Machine Learning

Future autonomous rigs rely heavily on machine learning and artificial intelligence to improve operations. The systems will continually analyse the data collected from digital twins, sensors and old drilling records to enhance drilling efficiency adjust to complex geological conditions, and increase the accuracy of well placement. Self-learning algorithms will allow drillers to modify their plans in real-time, becoming more intelligent with every operation.

AI-driven Autonomous Underwater Vehicle (AUV)

- Integration of Real-Time Digital Twins and Predictive Modeling

Digital twins will be more interactive and integrated, allowing real-time simulations of equipment wellbores and their surrounding geological formations. Operators can use these upgraded virtual environments in order to predict problems and simulate drilling scenarios and take decisions based upon high-quality modeling. Predictive maintenance based on these systems can further cut down on the chance of equipment failure and downtime that is not planned for.

- Expansion of Edge Computing and Onboard Autonomy

Computing capabilities for edge devices will improve in sophistication, which will allow more information processing and decision-making to happen directly within the equipment. This localized intelligence will become crucial for quick responses to fast shifts in pressure at subsurface, the fluid’s dynamics or equipment performance, especially in situations where cloud connection is restricted or is delayed.

- Strengthened Environmental Monitoring and Compliance

With more stringent environmental regulations coming soon autonomous rigs will come equipped with sophisticated monitoring and controlling systems that will limit emissions, avoid leaks and to ensure ecologically responsible drilling methods. AI-driven compliance and reporting systems will allow continuous monitoring of the ecological impact as well as assisting in the pursuit of sustainability targets across the offshore industry.

- Standardization and Regulatory Evolution

As autonomy becomes more commonplace the regulators and industry participants will be required to develop new governance and standards for operations that are not manned. The regulations will focus on security protocols, cybersecurity as well as liability and data integrity. International cooperation is crucial in harmonising best practices and facilitating safe, autonomous drilling across borders operations.

- Upskilling the Workforce for a Digital Future

While automation can reduce the requirement for physical labor overseas however, it also increases the need for digitally-savvy professionals. The next generation of workers will require skills in AI robotics, robotics, data analysis and systems engineering. Education and training programs are crucial to train engineers and operators to manage and sustaining self-contained offshore technology.

Summary

Autonomous offshore drilling rigs are an enthralling leap towards the future of energy exploration. With enhanced precision, safety and sustainability, these advanced systems are set to redefine how we can tap into undersea resources. While challenges remain, the benefits of autonomy in offshore drilling for the energy sector and global economy are potentially transformative.