A Comprehensive Guide to Enhanced Oil Recovery Techniques

Once conventional oil reservoirs are depleted, Enhanced Oil Recovery (EOR) techniques come into play, extracting additional oil from the reservoir. Similar to wringing out a wet sponge, EOR employs methods such as heat, gas injection, or chemical treatments to modify the oil’s viscosity, drive it towards extraction wells, or alter its flow characteristics. While EOR prolongs the life of oil fields and may mitigate environmental impacts, it comes with significant costs and is not without its own ecological considerations. Nonetheless, it remains a critical strategy for optimizing oil production amidst constraints on resources and sustainability concerns.

Role of Enhanced Oil Recovery Techniques

As traditional oil reservoirs diminish and the world’s energy dynamics evolve, Enhanced Oil Recovery (EOR) methods are increasingly recognized as pivotal in prolonging the viability of current oil fields and upholding energy stability. Beyond merely enhancing extraction rates, EOR serves as a multifaceted approach to responsible resource stewardship, fostering economic resilience, and addressing environmental concerns.

- Unlocking Remaining Potential: EOR goes beyond the natural pressure and secondary methods that typically recover only a fraction of the oil within a reservoir. By employing thermal, chemical, and gas injection techniques, EOR unlocks trapped oil, significantly increasing ultimate recovery rates. This extends the productive life of mature fields, delaying the need for exploration and development of new, potentially pristine, areas.

- Economic Imperative: EOR contributes significantly to energy security by bolstering domestic oil production, reducing reliance on imports, and creating valuable jobs within the oil and gas industry. With rising global energy demand, EOR helps bridge the gap between existing resources and alternative energy solutions, providing much-needed stability during the transition.

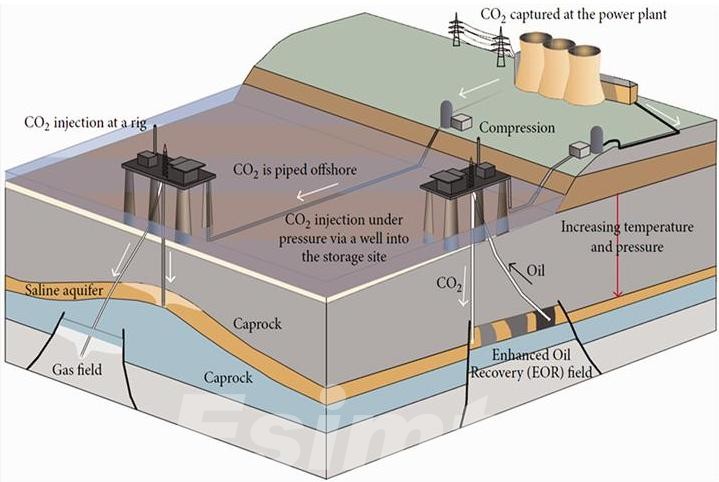

- Environmental Considerations: While traditionally perceived as contributing to environmental concerns, EOR techniques are evolving to address these issues. Some methods, like CO2 injection forEOR, can actually store captured carbon dioxide underground, contributing to greenhouse gas mitigation efforts. Additionally, EOR can reduce water usage compared to traditional methods, minimizing the environmental footprint of oil production.

- Challenges and the Path Forward: Despite its advantages, EOR faces challenges. Its implementation can be expensive and energy-intensive, and its effectiveness varies depending on reservoir characteristics. Ongoing research and development are crucial to enhance efficiency, reduce costs, and minimize environmental impact. Additionally, collaborative efforts are needed to develop regulations and incentives that encourage widespread adoption of sustainable EOR practices.

In a world grappling with energy demands, resource scarcity, and environmental concerns, EOR techniques play a vital role. By unlocking additional oil reserves, boosting economic activity, and offering potential environmental benefits, EOR serves as a bridge to a more sustainable future. Continued advancements and responsible implementation are key to maximizing its potential and ensuring a secure and responsible energy future.

Methods of Enhanced Oil Recovery Techniques in the Petroleum Industry

Enhanced oil recovery (EOR) is a set of techniques used to extract more oil from an oil reservoir after primary and secondary recovery methods have been exhausted. Primary recovery relies on the natural pressure of the reservoir to push oil towards the wellbore. Secondary recovery methods, such as waterflooding, inject water into the reservoir to maintain pressure and sweep oil towards the wellbore. However, even after these methods are used, a significant amount of oil can still remain trapped in the reservoir. EOR methods are used to recover this remaining oil.

- Thermal methods: These methods involve heating the oil reservoir to reduce its viscosity and make it easier to flow. Common thermal methods include steamflooding, in which steam is injected into the reservoir, and fireflooding, in which air is injected into the reservoir and ignited.

- Chemical methods: These methods involve injecting chemicals into the reservoir to change the properties of the oil or rock, making it easier to recover the oil. Common chemical methods include polymer flooding, in which polymers are injected to increase the viscosity of water and improve its sweep efficiency, and surfactant flooding, in which surfactants are injected to reduce the interfacial tension between oil and water, allowing the water to flow more easily through the reservoir and mobilize the oil.

- Gas injection methods: These methods involve injecting gas, such as carbon dioxide (CO2) or nitrogen, into the reservoir to reduce the viscosity of the oil and increase reservoir pressure. CO2 injection can also have the added benefit of storing carbon dioxide underground, which can help to mitigate climate change.

The choice of EOR method depends on a number of factors, including the type of oil, the geology of the reservoir, and the economic feasibility of the project.

EOR methods can be very effective in increasing oil recovery rates. For example, EOR can recover an additional 30-60% of the oil that remains in a reservoir after primary and secondary recovery methods have been used. However, EOR methods can also be expensive and complex to implement.

The use of EOR is becoming increasingly important as the world’s oil reserves mature and it becomes more difficult to find new oil. EOR is expected to play a major role in meeting the world’s growing demand for oil in the coming decades.

Environmental Concerns of Enhanced Oil Recovery Techniques

While Enhanced Oil Recovery (EOR) techniques offer valuable economic and energy security benefits, they also raise significant environmental concerns that require careful consideration and responsible management. Here’s a closer look at the key issues:

1. Greenhouse Gas Emissions:

Thermal methods: Burning natural gas for steam injection releases greenhouse gases directly, contributing to climate change.

Carbon dioxide (CO2) injection: While potentially storing captured CO2 underground, leakage risks can negate the benefits and release potent greenhouse gases.

Chemical EOR: Some chemicals used can be volatile and contribute to greenhouse gas emissions during production and processing.

2. Water Contamination:

Increased water use: Some EOR methods, like waterflooding, require large volumes of water, potentially stressing freshwater resources in arid regions.

Brine disposal: Produced water from EOR can be highly saline and contain contaminants, requiring careful treatment and disposal to avoid contaminating freshwater aquifers or surface water bodies.

Chemical spills and leaks: Accidental spills or leaks of chemicals used in EOR can contaminate soil and water, impacting ecosystems and human health.

3. Land Use and Ecosystem Impacts:

Surface infrastructure expansion: Building and operating EOR facilities can require land clearing and disrupt ecosystems, impacting biodiversity and habitat connectivity.

Seismic activity: Certain EOR techniques, like steam injection, can trigger seismic activity in some areas, raising concerns about potential earthquakes and infrastructure damage.

Air pollution: Emissions from EOR facilities, including volatile organic compounds and nitrogen oxides, can contribute to air quality issues in the surrounding areas.

4. Additional Concerns:

Energy intensity: Some EOR methods are energy-intensive, potentially negating their environmental benefits if the energy source is fossil fuel-based.

Long-term impacts: The long-term environmental consequences of certain EOR methods, such as CO2 storage permanence and chemical degradation, are still under investigation.

Technological Advancements in Enhanced Oil Recovery Techniques

As the world grapples with diminishing conventional oil reserves and the pressing need for sustainable energy solutions, Enhanced Oil Recovery (EOR) techniques are experiencing a renaissance. Driven by cutting-edge technologies and a renewed focus on environmental responsibility, these advancements are pushing the boundaries of what’s possible, unlocking trapped oil resources while minimizing environmental impact.

1. SmartEOR: By leveraging artificial intelligence (AI) and machine learning (ML), SmartEOR is revolutionizing reservoir characterization and optimization. Real-time data analysis and predictive models are enabling tailored EOR strategies for specific reservoir conditions, maximizing recovery efficiency and minimizing costs.

2. Nanotechnologies: Nanoparticles are finding diverse applications in EOR. They can act as targeted carriers for chemicals, enhancing their effectiveness and reducing environmental footprint. Additionally, nanofluids can improve sweep efficiency by altering fluid properties within the reservoir.

3. Advanced Monitoring and Diagnostics: High-resolution sensors and downhole monitoring systems are providing unprecedented insights into reservoir dynamics. This allows for real-time adjustments to EOR operations, optimizing performance and minimizing environmental risks.

4. CO2-EOR with Enhanced Geological Storage: Carbon capture, utilization, and storage (CCUS) technologies are being integrated with CO2-EOR, offering a dual benefit. Captured CO2 is injected into depleted reservoirs for enhanced oil recovery while simultaneously storing it underground, contributing to greenhouse gas mitigation.

5. Microbial EOR: This emerging technique utilizes microorganisms to extract oil by altering its viscosity or enhancing oil mobilization. While still in its early stages, microbial EOR holds promise for a more sustainable and environmentally friendly approach to oil recovery.

Conclusion

Enhanced Oil Recovery (EOR) techniques represent a valuable tool for the petroleum industry to maximize production from existing oil reservoirs. By employing a variety of methods, including thermal, chemical, and miscible gas injection, EOR techniques help to extend the productive life of oil fields and optimize the recovery of valuable resources. However, it is essential for the industry to address environmental concerns associated with EOR operations and adopt sustainable practices to minimize their impact on the environment. With ongoing technological advancements, the future of EOR holds promise for further enhancing oil recovery efficiency while mitigating environmental risks.