The Rise of AI-powered Downhole Tools

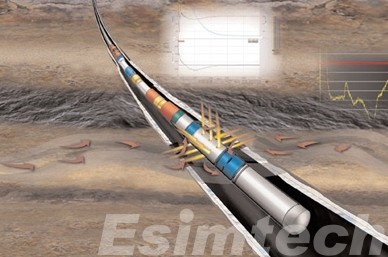

For decades, the oil and gas industry has relied on a plethora of specialized tools deployed deep underground, known as downhole tools, to perform crucial tasks like drilling, logging, completing wells, and optimizing production. These tools operate in a harsh and complex environment, enduring immense pressure, extreme temperatures, and exposure to corrosive fluids. Now, the emergence of Artificial Intelligence (AI) is poised to revolutionize this domain, ushering in a new era of efficiency, safety, and cost-effectiveness in downhole operations.

What are AI-powered Downhole Tools

AI-powered downhole tools are advanced equipment used in the oil and gas industry for various tasks related to drilling, completion, and production operations in oil wells. These tools incorporate artificial intelligence (AI) technologies to enhance their functionality, efficiency, and reliability in extracting hydrocarbons from the subsurface reservoirs.

At their core, AI-powered downhole tools leverage sophisticated algorithms and data analytics techniques to optimize decision-making processes and improve overall performance. This integration of AI allows these tools to adapt to dynamic downhole conditions, make real-time adjustments, and provide valuable insights into well operations, ultimately leading to increased productivity and cost savings.

Examples of AI technologies integrated into downhole tools include:

1. Machine Learning Algorithms

Machine learning algorithms are utilized to analyze vast amounts of data collected from downhole sensors, such as pressure, temperature, and flow rate measurements. These algorithms can identify patterns, anomalies, and correlations within the data to predict potential issues, optimize drilling parameters, and improve wellbore stability. For instance, machine learning algorithms can predict the onset of drilling dysfunctions, such as stuck pipe or wellbore instability, allowing operators to take preemptive actions to mitigate risks and avoid costly downtime.

2. Predictive Analytics

AI-powered downhole tools leverage predictive analytics techniques to forecast future downhole conditions and performance trends based on historical data and real-time measurements. By analyzing past drilling experiences and downhole dynamics, these tools can predict equipment failures, optimize maintenance schedules, and recommend optimal drilling strategies to maximize production efficiency. Predictive analytics also enable operators to anticipate reservoir behavior and optimize well placement, enhancing overall reservoir recovery and economic returns.

3. Autonomous Control Systems

Some AI-powered downhole tools incorporate autonomous control systems that enable them to make autonomous decisions and adjustments without human intervention. These systems use AI algorithms to interpret downhole data in real-time and automatically adjust drilling parameters, such as weight on bit (WOB), rotary speed, and mud flow rate, to optimize drilling performance and minimize operational risks. Autonomous control systems can also facilitate remote monitoring and control of downhole operations, enabling operators to efficiently manage multiple wells from centralized control centers.

How AI is Transforming Downhole Tools

Here’s a breakdown of how AI is transforming downhole tools and bringing a paradigm shift to the oil and gas industry:

1. Intelligent Optimization

- Adaptable Performance: Unlike traditional tools with fixed parameters, AI-powered tools analyze factors like rock formations, temperature, and pressure. They intelligently adjust settings in real-time for improved drilling speeds, lower wear and tear, and better energy efficiency.

- Autonomous Actions: Advanced AI capabilities could lead to tools making autonomous decisions based on data analysis. This optimizes processes without constant human input, reducing reaction times and improving efficiency.

2. Predictive Maintenance

- Proactive, Not Reactive: AI constantly monitors sensors for irregularities like vibrations, temperature spikes, or pressure changes. It pinpoints potential component failures before they happen. This allows for scheduled maintenance instead of costly reactive repairs and downtime.

- Preventing the Unforeseen: AI’s ability to spot subtle patterns in data uncovers trends human engineers might miss. Addressing issues before they escalate prevents major equipment failures and keeps operations running safely and smoothly.

3. Unlocking the Power of Data

- Beyond Human Capacity: Downhole operations generate enormous amounts of data. AI processes it with unmatched speed and accuracy, finding complex patterns and correlations that humans would be unable to.

- Data-Driven Decisions: The insights gained from AI-powered analysis empower operators to fine-tune wellbore strategies, optimize production, address hidden issues, and reduce risk. Every decision becomes informed and calculated.

4. The Future of AI in the Downhole Environment

- Self-Learning Systems: AI-powered tools could potentially analyze their own performance and continually improve based on their experiences, creating a continuously evolving cycle of optimization.

- Tool Collaboration and Safety: Networks of AI-powered tools will communicate with each other and surface-level systems. This seamless integration promotes data-driven safety alerts, ensuring safer downhole operations and protection of vital equipment.

AI isn’t just a buzzword for downhole tools – it’s a transformative power. By turning data into actionable insights, AI makes operations more efficient, more predictable, and inherently safer.

Benefits of AI-powered Downhole Tools

AI-powered downhole tools offer numerous benefits to the oil and gas industry. By leveraging artificial intelligence, these tools enhance operational efficiency, optimize drilling parameters, and improve overall well performance. They enable real-time monitoring and analysis of downhole conditions, allowing for proactive decision-making to mitigate risks and avoid costly downtime.

Additionally, AI-powered downhole tools facilitate predictive maintenance, helping operators anticipate equipment failures and optimize maintenance schedules, thereby reducing operational disruptions and extending asset lifespan.

Furthermore, these tools enable data-driven decision-making, leading to improved reservoir characterization, optimized well placement, and enhanced hydrocarbon recovery.

Overall, the integration of AI in downhole tools enhances productivity, reduces costs, and enables more sustainable and efficient oil and gas operations.

Challenges and Considerations of AI-powered Downhole Tools

While AI-powered downhole tools offer significant potential to revolutionize the oil and gas industry, addressing challenges related to data quality, technical complexity, regulatory compliance, and adoption barriers is critical for successful implementation.

- Data Quality and Integration

Ensuring high-quality data from diverse sources is crucial for AI-powered downhole tools. This involves managing data consistency, accuracy, and compatibility across platforms and sensors. Investments in data infrastructure and standardized protocols are necessary to address these challenges.

- Technical Complexity

Implementing AI technologies requires specialized expertise in data science and programming. Collaborative efforts between engineers, geoscientists, and data scientists are essential to navigate technical complexities. Upskilling the workforce or partnering with external experts can help overcome this challenge.

- Regulatory Compliance

AI deployment must adhere to strict regulations on data privacy, safety, and environmental protection. Companies must ensure compliance with legal frameworks and implement robust safety measures to mitigate risks. This requires navigating regulatory requirements and establishing comprehensive compliance mechanisms.

- Adoption Barriers

Resistance to change and upfront investment costs may hinder the adoption of AI-powered downhole tools. Overcoming these barriers necessitates leadership commitment, change management strategies, and clear communication. Demonstrating tangible benefits through pilot projects can build confidence and promote adoption within the industry.

Conclusion

The rise of AI-powered downhole tools marks a significant turning point in the oil and gas industry. These intelligent tools offer the potential to revolutionize how we explore, develop, and produce hydrocarbons, leading to increased efficiency, enhanced safety, and improved resource management. While challenges remain, the future holds immense promise for AI to not only optimize existing operations but also pave the way for entirely new approaches to extracting valuable resources from the depths of the earth. As AI continues to evolve, so too will its transformative power in the oil and gas industry, shaping the future of energy exploration and production.