What are Offshore Oil Rigs: Everything You Need to Know

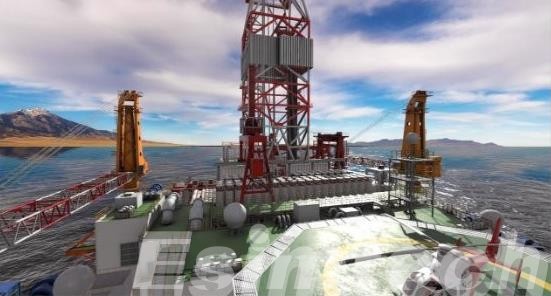

Offshore oil rigs stand as iconic symbols within the global energy sector. These colossal installations, strategically located miles from the coastline, have served as indispensable contributors to the world's energy requirements for numerous years. They epitomize an extraordinary fusion of engineering excellence, inventive solutions, and a commitment to environmental stewardship.

In this extensive article, we will embark on an in-depth exploration of offshore oil rigs, casting light upon their architectural intricacies, operational intricacies, environmental implications, and their profound significance within the energy arena. Furthermore, we will venture into the realm of simulation technology and their role in training personnel for the intricate operations conducted on offshore rigs.

The Birth of Offshore Oil Rigs

The origins of offshore oil exploration date back to the early 20th century, prompted by the depletion of onshore oil reserves and the industry's pursuit of fresh hydrocarbon sources in oceanic expanses. An early milestone in this journey occurred in 1896, along the California coast, where the first offshore drilling platform emerged. This pioneering structure, constructed from wood, stands in stark contrast to the sophisticated offshore rigs that now dominate our offshore landscapes.

With the passage of time, offshore drilling has undergone a remarkable transformation. This evolution has been characterized by the development of cutting-edge technologies and a heightened comprehension of the intricate challenges posed by the marine environment. The surging demand for offshore drilling has been underpinned by the revelation of extensive, untapped reservoirs of oil and gas concealed beneath the ocean floor.

Working Principles of Offshore Oil Rigs

Offshore oil rigs are a testament to human ingenuity and engineering excellence. Their operation involves a series of intricate processes that ensure the extraction, processing, and transportation of hydrocarbons from deep beneath the seabed to onshore facilities. Here is an overview of how offshore oil rigs work:

- Exploration and Drilling: The journey begins with seismic surveys to identify potential oil and gas reserves. Once a suitable location is found, exploration wells are drilled to confirm the presence of hydrocarbons. If successful, production wells are drilled to extract the resources.

- Production: Oil and gas are brought to the surface through the production wells. On fixed platforms, this often involves the use of drilling rigs and wellheads. On floating production systems, the oil and gas are transported through flexible risers or pipelines to the surface facilities.

- Processing: The extracted fluids contain a mixture of oil, gas, and water. Separation and processing facilities on the rig separate these components. Advanced technology is used to remove impurities, separate the oil and gas, and compress the gas for transportation.

- Storage: On FPSOs and some floating platforms, the oil is stored in tanks until it can be offloaded onto shuttle tankers for transportation to onshore refineries. Gas may be reinjected into the reservoir, flared, or transported via pipelines.

- Environmental Considerations: Offshore oil rigs are equipped with various environmental protection systems. These include oil spill containment measures, gas emission control systems, and strict adherence to safety protocols to minimize environmental impact.

Types of Offshore Oil Rigs

1. Fixed Platforms

Fixed platforms serve as the foundational structures of offshore drilling operations. These robust structures are firmly anchored to the seabed, extending their towering superstructures above the water's surface. They are typically deployed in shallow waters where the water depth remains within a few hundred feet. Fixed platforms encompass a variety of subtypes, each tailored to specific conditions and requirements:

- Jacket Platform

Recognizable by their lattice-like framework composed of vertical steel members known as jackets, these platforms offer exceptional stability and a robust foundation for drilling and production equipment.

- Caisson Platform

Caisson platforms utilize watertight, hollow chambers (caissons) to provide buoyancy, making them ideal for regions with soft or marshy seabeds. They excel in environments characterized by muddy substrates.

- Concrete Gravity Platform

Crafted from reinforced concrete, these platforms rely on their substantial weight for stability. They are commonly deployed in areas where enhanced stability is of paramount importance.

2. Compliant Tower

Compliant towers are a distinctive type of fixed offshore platform designed to withstand the challenging conditions of deepwater drilling, particularly in areas prone to high waves, strong currents, and extreme weather events like hurricanes. These towers are engineered to offer exceptional flexibility and structural integrity, ensuring the safety of personnel and the reliability of drilling and production operations in harsh marine environments.

3. Spar Platform

Compliant towers are a distinctive type of fixed offshore platform designed to withstand the challenging conditions of deepwater drilling, particularly in areas prone to high waves, strong currents, and extreme weather events like hurricanes. These towers are engineered to offer exceptional flexibility and structural integrity, ensuring the safety of personnel and the reliability of drilling and production operations in harsh marine environments.

4. Tension-Leg Platform (TLP)

Tension-Leg Platforms (TLPs) are a specialized type of offshore platform employed primarily for deepwater drilling and production operations in challenging marine environments. These platforms are renowned for their exceptional stability and ability to withstand extreme wave conditions. TLPs operate on a unique principle that involves tensioned vertical tendons to secure the platform to the seabed.

5. Floating Production, Storage, and Offloading (FPSO) Vessel

Floating Production, Storage, and Offloading (FPSO) vessels are a crucial component of offshore oil and gas production and represent a versatile solution for extracting hydrocarbons from deepwater reserves. FPSOs are essentially floating production facilities that combine drilling, processing, storage, and offloading capabilities, all integrated into a single vessel. These vessels play a pivotal role in the oil and gas industry, particularly in remote and challenging offshore environments.

6. Drillship

A drillship stands as a highly specialized vessel meticulously crafted for offshore drilling undertakings within the confines of deepwater and ultra-deepwater environments. These maritime giants boast state-of-the-art drilling apparatus and cutting-edge technology, affording them unparalleled mobility to venture into distant offshore realms. Drillships assume a pivotal role in the pursuit of uncovering and harnessing hydrocarbon reserves concealed beneath the ocean floor.

7. Semi-Submersible

Semi-submersible rigs are buoyant structures with large water ballast tanks. By flooding these tanks, the rig can partially submerge, creating stability. Semi-submersibles are commonly used for drilling operations in deepwater and harsh sea conditions.

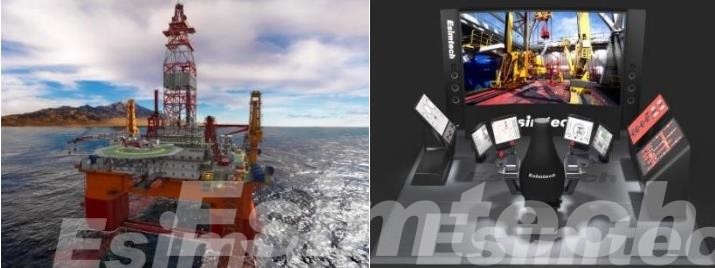

The Role of Simulation Technology in Offshore Oil Rig Operations

Operating offshore oil rigs is an intricate endeavor that demands a well-trained and proficient workforce. In this context, simulation technology have emerged as indispensable tools for preparing personnel for the complexities of offshore rig operations. Here's a closer look at how simulators are applied in this capacity:

1. Immersive Training Environments

Offshore rig simulators excel at recreating authentic offshore settings, complete with varying weather conditions, equipment glitches, and emergency situations. These emergency simulation training systems provide trainees with the opportunity to encounter and tackle real-world challenges within a secure and controlled environment.

2. Skill Refinement

Offshore drilling Simulators serve as invaluable platforms for honing essential skills essential for offshore operations. Trainees can repeatedly practice tasks such as drilling, well control, and emergency response procedures until they attain a high degree of proficiency.

3. Safety Protocols

Safety is paramount in offshore oil rig operations, and simulators are instrumental in imparting comprehensive safety training. This encompasses fire drills, evacuation protocols, and the proper handling of hazardous materials, ensuring that personnel are well-prepared to respond to critical safety situations.

4. Operational Efficiency

Simulation technology contributes significantly to enhancing the efficiency of personnel by simulating diverse operational scenarios. This fosters improved decision-making skills and enables quicker response times during real-time operations, ultimately enhancing overall operational efficiency.

5. Cost-Efficiency

Utilizing oil and gas simulators for training purposes can lead to substantial cost savings. By eliminating the need to utilize actual equipment and resources for training, companies can reduce the expenses associated with on-the-job training, making the training process both cost-effective and resource-efficient.

Conclusion

In summary, offshore oil rigs are impressive engineering achievements that have greatly impacted the world's energy production. These massive structures, whether fixed platforms or floating systems, serve as crucial centers for extracting, processing, and transporting oil and gas resources. However, they are under increasing scrutiny due to their environmental impact.

As we move towards a more sustainable energy future, offshore oil rigs will undergo changes. Whether they continue to play a significant role in energy production or take on new responsibilities, one thing is certain: they will remain central to the global energy industry, showcasing human innovation. Additionally, the use of simulation technology in personnel training is vital for ensuring the ongoing safe and efficient operation of these structures, preparing the workforce for future challenges in offshore drilling.