What are Offshore Platforms: Functions, Types and Design Considerations

Offshore platforms are massive constructions that serve as the backbone of the worldwide oil and gas industry, allowing lucrative hydrocarbon resources to be extracted from beneath the ocean floor. These technical marvels are a monument to human ingenuity, combining cutting-edge technology with precision design and a thorough awareness of the problems faced by the marine environment. In this article, we’ll delve into the world of offshore platforms, exploring their functions, types and design considerations.

Functions of Offshore Platforms

Offshore platforms serve several critical functions within the oil and gas industry:

Drilling and Production

Offshore platforms host drilling rigs and other equipment used to extract hydrocarbons from the seabed. They provide a sturdy platform for underwater drilling operations and housing oil and gas processing facilities.

Storage

Many offshore platforms include storage tanks for temporary storage of extracted oil and gas before transportation to onshore facilities.

Living Quarters

Some platforms accommodate personnel who work on-site, providing living quarters, kitchens, and recreational facilities.

Common Types of Offshore Platforms

Offshore platforms are classified into several types, each of which is designed to satisfy certain needs and environmental circumstances.

Fixed Platforms

Jacket Platforms: These are steel constructions with vertical legs (jackets) that reach the seafloor. Jacket platforms are popular in shallow to moderate water depths because they provide stability and longevity.

Gravity-Based Platforms: These platforms are gigantic concrete structures that rely on their weight to remain anchored to the seafloor. They can support drilling and production operations and are appropriate for shallow water sites.

Floating Platforms

Tension Leg Platforms (TLPs): TLPs are floating constructions that are connected to the seafloor by vertically tensioned tendons. They are intended for usage in deep water and provide exceptional stability in choppy waves.

Spar Platforms: Spar platforms are cylindrical, deep-draft floating constructions that are tethered to the seafloor. They are suitable for deepwater applications and have a narrower profile than other floating platforms.

Semi-Submersibles: These are buoyant platforms that partially submerge themselves in the water, making them very stable. This type of floating platforms is often used for drilling operations and can be easily moved from one location to another.

Compliant Towers

These are tall, slender structures that sway in response to the passage of the waves. Compliant towers are employed in deepwater environments and are especially well-suited for hurricane-prone areas. They may move with the waves while remaining stable.

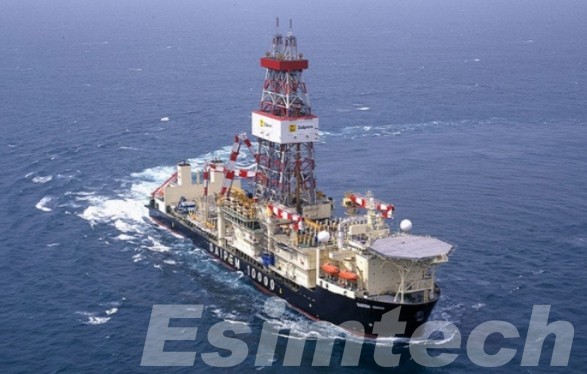

FPSOs (Floating Production Storage and Offloading)

FPSOs are vessels equipped with oil and gas processing facilities. They are moored to the seabed and used in deepwater areas. FPSOs store and process hydrocarbons before offloading them onto shuttle tankers or pipelines.

Wellhead Platforms

These platforms are typically smaller and focus on housing the wellheads and initial processing equipment. They are often used in conjunction with larger production platforms or FPSOs.

Subsea Production Systems

In some cases, instead of traditional platforms, subsea production systems are used. These systems involve placing wellheads and processing equipment on the seabed, and the extracted hydrocarbons are transported directly to the shore through pipelines.

Artificial Islands

In some regions, especially in shallow waters, artificial islands are constructed to serve as drilling and production hubs. These islands are built from sand and rock and can support various facilities.

Design Considerations of Offshore Platforms

Designing offshore platforms is a difficult and highly specialized procedure that necessitates careful consideration of several elements in order to assure the safety, reliability, and functionality of these structures.

Environmental Conditions

Water Depth: The depth of the water at the platform location is a primary factor in determining the type of platform to be used. Shallow-water platforms differ significantly from those designed for deepwater or ultra-deepwater operations.

Weather and Wave Conditions: Offshore platforms must be designed to endure extreme weather conditions such as storms, high winds, and waves. Design parameters are based on historical weather trends and extreme events.

Seismic Activity: In regions prone to earthquakes, platforms must be designed to withstand seismic forces. This includes considering the platform’s response to ground motion and the potential for liquefaction of the seabed.

Seabed Conditions

Seabed Stability: The type of seabed (e.g., soft mud, sand, rock) and its stability affect the platform’s foundation design and anchoring methods.

Geotechnical Surveys: Detailed geotechnical surveys are conducted to assess the seabed conditions, which inform foundation design and pile installation methods.

Safety Regulations and Standards

Industry Standards: Offshore platforms must adhere to industry-specific safety and design standards, which vary by region. These standards cover everything from structural integrity to fire and explosion protection.

Regulatory Compliance: Compliance with local, national, and international legislation is critical to ensuring worker safety and environmental preservation.

Structural Design

Materials: The selection of materials for platform construction is crucial to ensure durability and resistance to corrosion in the harsh marine environment. Common materials include high-strength steel and corrosion-resistant alloys.

Structural Integrity: Engineers examine the structural integrity of the platform under various loading situations, including as wave forces, wind, and equipment weight, using advanced modeling and simulation methods.

Environmental Impact Mitigation

Oil Spill Contingency: Offshore platforms must have systems in place to contain and respond to oil spills. These include oil booms, skimmers, and emergency response plans.

Emission Controls: Platforms often implement technologies to minimize air emissions and reduce their environmental footprint.

Operational Efficiency

Layout and Functionality: The platform’s layout is designed for efficient operations, including drilling, production, and processing. This includes the arrangement of wellheads, processing equipment, and living quarters (if applicable).

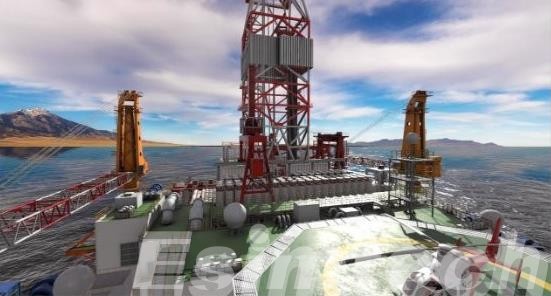

A drilling and well control simulator creates a three-dimensional representation of the drilling rig and wellbore. By simulating various drilling techniques and parameters, the simulator can be used to maximize drilling performance by allowing staff to analyze and alter drilling parameters in real-time. This kind of drilling simulation system can be considered for the designing of offshore platforms.

Maintenance Access: The platform’s design prioritizes accessibility for routine maintenance and inspections.

Cost Efficiency

Project Economics: It is critical to balance initial construction expenses with long-term operational efficiency and maintenance costs. Engineers strive towards cost-effectiveness while maintaining safety and reliability.

Decommissioning Planning: Consideration must be given to the eventual decommissioning of the platform, including the removal or abandonment of equipment and structures.

Environmental Impact Assessment

Ecological Impact: The potential impact on the local marine ecosystem and wildlife must be assessed. Some platforms become artificial reefs over time, which can positively impact marine biodiversity.

Cultural and Social Impact: The existence of offshore platforms can have social and cultural consequences for communities nearby. These factors are critical in project planning and stakeholder involvement.

Designing offshore platforms is a multidisciplinary effort that involves engineers, geologists, environmental scientists, and regulatory experts. The goal is to create structures that can safely and efficiently extract hydrocarbon resources while minimizing environmental impact and ensuring the well-being of the people who work on them.

Conclusion

Offshore platforms enable the exploration and extraction of important energy resources from the ocean floor. These structures, whether permanent or floating, are precision-engineered to resist harsh environmental conditions while complying with demanding safety and environmental laws. Offshore platforms continue to play an important role in satisfying global energy demands and fostering innovation in the offshore industry, despite the fact that they bring both economic benefits and environmental dangers.