What Do You Know About Whipstock Drilling

Whipstock drilling is a directional drilling technique that is used to change the direction of an existing wellbore. This technique is typically used to sidetrack from an existing wellbore, which means that a new wellbore is drilled from the same wellhead as the existing wellbore. This can be done for a number of reasons, such as to access multiple reservoirs from a single well or to re-enter a well that has been plugged and abandoned.

History of Whipstock Drilling

The first whipstock was made of wood and was simply lowered into the wellbore and oriented with the whip face in the desired direction. The whipstock was then anchored in place by driving wooden wedges between it and the casing. This method was not very effective, and the sidetracks were often crooked and difficult to control.

Improvements

In the 1940s, whipstocks were made of steel and were designed to be more stable and easier to control. The first steel whipstocks were still anchored in place with wooden wedges, but later designs were anchored in place with cement. This made the sidetracks more accurate and less likely to collapse.

Modern Whipstock Drilling

Today, whipstock drilling is still used in some applications, but it has been largely superseded by more sophisticated directional drilling techniques. However, whipstock drilling is still a valuable technique for certain applications, such as when drilling through formations with high fracture gradients.

Here are some of the key milestones in the history of whipstock drilling:

- 1930s: The first whipstocks are developed.

- 1940s: Steel whipstocks are developed.

- 1950s: Cement is used to anchor whipstocks in place.

- 1960s: Directional drilling techniques become more sophisticated.

- 1970s-present: Whipstock drilling is used in a variety of applications.

Principles of Whipstock Drilling

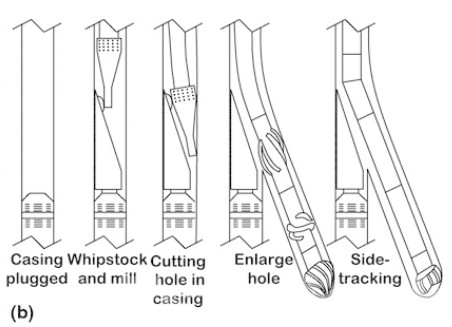

The whipstock is the main component of a whipstock drilling system. It is a wedge-shaped device that is made of steel or another hard material. The whipstock has a sloping face that is designed to deflect the drill bit in the desired direction. The whipstock is anchored in place in the wellbore by cement.

1. Setting the whipstock

The first step in whipstock drilling is to set the whipstock in place in the wellbore. This is done by lowering the whipstock into the wellbore and positioning it at the desired depth. The whipstock is then anchored in place by cement.

2. Initiating the sidetrack

Once the whipstock is in place, the next step is to initiate the sidetrack. This is done by drilling into the whipstock with a directional drilling tool. The directional drilling tool is a specialized tool that is designed to follow the sloping face of the whipstock and deflect the drill bit in the desired direction.

3. Drilling the sidetrack

After the sidetrack has been initiated, the next step is to drill the sidetrack to the desired depth. This is done using a conventional drilling tool.

4. Completing the sidetrack

Once the sidetrack has been drilled to the desired depth, the next step is to complete the sidetrack. This may involve running casing, installing a liner, or completing the well.

Applications of Whipstock Drilling

Whipstock drilling is a directional drilling technique that has been used for over 90 years. It is a versatile and effective technique that can be used in a variety of wellbore conditions. Whipstock drilling is used to create a sidetrack from an existing wellbore. This can be done to:

1. Access multiple reservoirs from a single well.

By creating a sidetrack from an existing wellbore, operators can access multiple reservoirs without having to drill a new well. This can save time and money, and it can also reduce the environmental impact of drilling operations.

2. Re-enter wells that have been plugged and abandoned.

Sometimes, wells that have been plugged and abandoned may need to be re-entered to produce additional oil or gas. Whipstock drilling can be used to re-enter these wells safely and efficiently.

3. Drill through obstructions.

If there is an obstruction in the wellbore, such as a piece of equipment or a collapsed section of casing, whipstock drilling can be used to drill through the obstruction. This can allow operators to continue drilling to the desired depth.

Advantages and Disadvantages of Whipstock Drilling

Whipstock Drilling technique enables the creation of a sidetrack from an existing wellbore, offering several advantages in various drilling scenarios. However, it also comes with certain drawbacks that need to be considered. Here is a comparison of the advantages and disadvantages of whipstock drilling.

Advantages

- Relative simplicity and affordability: Whipstock drilling is a relatively straightforward and cost-effective directional drilling technique compared to more sophisticated methods. The equipment and procedures involved are less complex, requiring less specialized expertise and reducing overall operational costs.

- Adaptability to diverse wellbore conditions: Whipstock drilling can be effectively employed in various wellbore environments, including those with challenging geological formations or restricted access. Its versatility makes it a suitable choice for a wide range of drilling situations.

- Potential for accessing multiple reservoirs: Whipstock drilling can be used to create sidetracks from existing wells, allowing for the exploration and production of multiple reservoirs from a single wellbore. This approach can significantly enhance resource recovery and optimize field development strategies.

Disadvantages

- Directional control challenges: Controlling the precise direction of the sidetrack can be challenging with whipstock drilling, particularly in formations with varying hardness or when drilling through fractured zones. This can lead to deviations from the intended path, potentially resulting in complications or missed targets.

- Safety concerns in specific scenarios: Whipstock drilling may pose safety risks in certain situations, such as when drilling through formations with high fracture gradients or in areas with unstable wellbore conditions. Improper execution or inadequate precautions can lead to wellbore instability, equipment failure, or environmental hazards.

- Limitations in some applications: Whipstock drilling may not be the most suitable technique for certain applications, such as drilling highly deviated or horizontal wells. More advanced directional drilling methods may be required for these specialized applications.

In conclusion, whipstock drilling offers a range of advantages, including simplicity, versatility, and the ability to access multiple reservoirs or re-enter plugged wells. However, it also presents challenges in controlling the sidetrack direction and requires careful consideration of safety and environmental factors. The choice of whether to employ whipstock drilling depends on the specific wellbore conditions, drilling objectives, and risk tolerance.

Conclusion

Whipstock drilling is a versatile and effective technique that can be used to solve a variety of wellbore problems. However, it is important to note that whipstock drilling can be difficult to control and can be risky in certain situations. Therefore, it is particularly important that the drilling crew is sufficiently skilled, so you can consider drilling simulation training. Simulation-based training tools provide operators with a safe and realistic environment to practice their skills and prepare for various operational scenarios. By simulating emergency situations and complex procedures, operators can develop the necessary knowledge and experience to handle real-world challenges effectively.