Why Choose Drillships and Why Simulation is Used As An Advanced Critical Technology in Drillships

Within the realm of offshore exploration and resource extraction, drillships have arisen as state-of-the-art vessels that amalgamate advanced technology, engineering prowess, and simulation capabilities to overcome the complexities of offshore drilling. These adaptable vessels epitomize human innovation, granting access to precious reserves beneath the ocean’s depths. This piece delves into the captivating universe of drillships, delving into their extraordinary attributes and the pivotal role that simulation technology plays in their operational achievements.

The Birth of Drillships

Drillships stand as maritime vessels meticulously crafted for the purpose of delving into the seabed to procure oil and gas reservoirs. These remarkable entities combine the characteristics of both ships and oil rigs, boasting advanced drilling apparatus, living accommodations for crew, and state-of-the-art technology that endows them with autonomous functionality even within remote and demanding landscapes.

The concept of drillships arose as the imperative to explore and exploit resources from increasingly profound waters gained prominence. In contrast to conventional fixed oil rigs rooted to the ocean bed, drillships offer the agility to relocate to diverse locales, adeptly aligning with the ever-shifting demands of exploration. This mobility affords drillships entry to hitherto inaccessible regions, unearthing untapped reserves concealed beneath the ocean’s expanse.

The Anatomy of a Drillships

A drillship is a specialized type of offshore drilling rig designed for deep-sea exploration and extraction of oil and gas resources from beneath the ocean floor. It is equipped with advanced drilling technology and facilities to support drilling operations in remote and challenging offshore environments. The anatomy of a drillship can be broken down into several key components:

- Hull and Structure

Hull: The hull of a drillship is designed to withstand harsh marine conditions, including waves, currents, and potential ice encounters. It is typically double-hulled for added safety.

Mooring System: Drillships are equipped with a mooring system or dynamic positioning (DP) system to maintain their position over the drilling site. Mooring systems involve a set of anchors and chains to secure the drillship, while DP systems use thrusters and advanced positioning technology to keep the vessel in place.

- Drilling Equipment

Derrick: The derrick is a tall, vertical structure used to support the drill string and drilling equipment. It provides the necessary height for drilling operations.

Drillstring: The drill string includes the drill pipe, drilling collars, and other components that connect the drill bit at the bottom to the drilling equipment at the surface. It allows for the transfer of power and rotation to the drill bit.

Top Drive: The top drive is a motorized device that hangs from the derrick and provides the rotational force needed to turn the drillstring and drill bit. It replaces the traditional rotary table and offers better control and efficiency.

Blowout Preventer (BOP): The BOP is a critical safety device installed on the seafloor to control well pressure and prevent blowouts (uncontrolled releases of oil or gas). It consists of various valves and rams that can seal the wellbore in case of emergencies.

Mud System: The mud system is responsible for circulating drilling fluid (mud) down the drillstring and back up the annulus to cool the drill bit, carry cuttings to the surface, and maintain wellbore stability. It also helps control downhole pressure.

- Living Quarters and Facilities

Accommodation: Drillships are equipped with living quarters to accommodate the crew, which can include drilling personnel, maintenance staff, and other support personnel.

Mess Rooms and Recreation Areas: Drillships provide facilities for meals, relaxation, and recreation to maintain the well-being of the crew during their time offshore.

Control Rooms: These rooms house the equipment and systems needed to monitor and control drilling operations, navigation, and other critical functions.

- Power and Propulsion

Engines and Generators: Drillships have powerful diesel engines and generators that provide the necessary electrical power for all onboard systems, including drilling equipment, accommodations, and navigation.

Thrusters: If equipped with a dynamic positioning system, the drillship will have thrusters (azimuth or tunnel thrusters) that enable precise maneuvering and positioning without relying on anchors.

Helipad: Many drillships feature a helipad for crew changes, supply deliveries, and emergency evacuations.

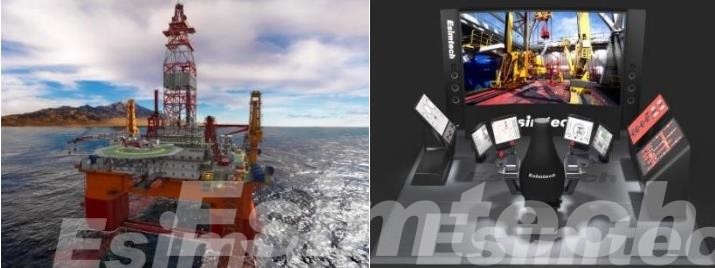

The Use of Simulation in Drillships

The operation of a drillship involves complex tasks that demand accuracy, precision, and adherence to safety protocols. This is where simulation technology steps in as a guiding beacon. A drilling simulation system is a tool that replicates real-world scenarios in a controlled environment, enabling users to experience and learn from complex situations without real-world consequences.

purpose

- Crew Training: The personnel operating drillships need to be well-versed in a range of tasks, from drilling operations to emergency response protocols. Simulators provide a safe space for crew members to practice these tasks and scenarios, enhancing their skills and confidence.

- Navigational Excellence: Drillships must position themselves accurately above drilling targets, a task that requires precise navigation and positioning. Simulators allow navigation officers to practice positioning the vessel under various conditions, ensuring optimal accuracy and minimizing the risk of errors.

- Drilling Procedures: The process of drilling involves multiple steps, each of which must be executed meticulously. Simulators allow drill operators to practice these procedures, optimizing efficiency and reducing accidents.

- Emergency Preparedness: In the event of an emergency, drillship crews need to react swiftly and effectively. Simulators facilitate emergency drills, enabling crew members to practice responses to scenarios such as blowouts, fires, or equipment malfunctions.

Advanced Simulations

Contemporary simulation technology has advanced to provide remarkably lifelike and deeply engaging experiences. High-fidelity simulators faithfully mimic the operations of a drillship, integrating up-to-the-minute data and dynamic variables like shifting weather patterns, ocean currents, and equipment reactions. This degree of authenticity effectively narrows the divide between theoretical training and actual on-site activities, significantly boosting the preparedness of drillship teams to tackle the obstacles they might face.

Simulating Success

With the ongoing advancement of technology, the potential of drillship simulators will also progress. The incorporation of artificial intelligence and machine learning can amplify the precision of simulations, enabling adaptable scenarios that react to user actions and responses.

Furthermore, the scope of simulation technology goes beyond training and readiness. Simulators play a pivotal role in the formulation and enhancement of drillship systems. Engineers can utilize simulations to replicate various equipment arrangements, assess possible hurdles, and refine the design prior to the commencement of construction.

Conclusion

The drillship stands as a remarkable testament to human inventiveness and unwavering determination to explore new horizons. Its capacity to tap into resources concealed far beneath the ocean floor stands as a transformative feat that shapes entire industries and economies. However, this achievement doesn’t arise in isolation; it emerges from the seamless fusion of leading-edge technology, inventive thinking, and simulation prowess that propels the drillship’s triumph.

As drillships persist in navigating the demanding waters of resource extraction, simulation technology will remain an unwavering companion, equipping crews, refining operations, and stretching the limits of what can be achieved. Through the prism of the drillship, we bear witness to the potency of human potential heightened by the tools of the digital era, propelling us ever deeper into the uncharted recesses of discovery.