How to manage oil drilling equipment?

With the continuous development of the petroleum industry worldwide, the consumption of petroleum machinery is also increasing, and the management of petroleum machinery and equipment is very important.

Maintenance and management of oil drilling equipment

Preventing failure of oil drilling equipment

Many petroleum machinery failures are caused by mechanical wear, and the wear between machinery will bring huge damage to the machinery. Here are some ways to prevent mechanical wear:

1. Reasonable and correct lubrication

Oil drilling machinery and equipment must ensure the precision of the equipment and the accuracy of the equipment at the same time, so it is necessary to maintain the gap between each of its components. To ensure a good gap between the components, in order to ensure that the equipment will not be worn due to vibration during operation.

In order to ensure the normal distance between each part, it is important to use the lubricant properly. The use of lubricants varies by machine, environment, and season. It cannot be used arbitrarily without considering the specific situation, let alone the use of fake and inferior products.

2. Train operators

The normal operation of machinery operators can reduce the probability of failure.

(1). Before starting the machine, check whether the coolant and oil reserves meet the standards.

(2). After starting, the machine should be preheated at a low speed, this is to allow the coolant and oil to reach the working temperature and avoid overload operation at low temperature.

(3). During the mechanical operation, it is necessary to always pay attention to whether the values of various thermometers are normal, so as to solve emergencies in a timely and effective manner.

(4). The operator should also be supervised while working.

Do a good job in compulsory maintenance of equipment.

In most cases, the failure of mechanical equipment is caused by overloading. To carry out daily maintenance and repair of equipment, but also to establish a sound maintenance system. Do a good job of daily supervision and inspection, reasonably allocate repair and maintenance resources, and ensure that the equipment is in a safe state.

Strengthen supervision over maintenance parts

Strict quality inspection of the repaired parts in storage is required to prevent mechanical failures caused by parts problems.

Improve the professional quality of maintenance personnel

Regularly train maintenance personnel, and strengthen the assessment of equipment management personnel and operation and maintenance personnel.

Personnel involved in managing equipment need to be supplemented with new knowledge and technology. The improvement of the skills and quality of maintenance personnel is conducive to the management of machinery and equipment.

Cleaning of oil drilling equipment

After the oil drilling equipment has been used for a period of time, a large amount of oil and soil will accumulate. Correctly clean the equipment before repairing to prepare for the next repair work, which is beneficial to improve the repair work efficiency and ensure the repair quality.

Basic principles of equipment cleaning

1. Prevent environmental pollution

Oil sludge during the cleaning of oil drilling rigs should be treated centrally and cannot be discharged casually to pollute the environment.

2. Ensure that various parts are cleaned and cleaned

In the repair, various parts have different cleaning requirements. It should be cleaned according to different repair processes to ensure that the quality of cleaning meets the requirements.

3. Prevent corrosion of parts

Any degree of corrosion is not allowed for precision parts. The anti-rust ability of the cleaning solution should be considered or other anti-rust measures should be adopted.

4. Safety and economic benefits

The method used should ensure safety. And the cleaning method used should be safe, low cost, easy to operate, and high efficiency.

Equipment cleaning method

1. Hot alkaline water cleaning

Soaking and cleaning with hot alkaline water can remove a large amount of sludge on the inner and outer surfaces of oil drilling equipment. However, alkali has a certain corrosive effect on metals. After soaking and cleaning with hot alkali water, the alkali solution remaining on the surface of parts and components should be cleaned with hot water.

2. Metal cleaner

Synthetic metal detergents contain surfactants, which can reduce the surface tension of the oil-water interface and produce various effects such as wetting, penetration, emulsification, and dispersion, so as to achieve the effect of removing grease and water-soluble dirt. It has the advantages of simple solution preparation, non-toxic, non-corrosive, non-flammable, non-explosive, and low cost.

3. Ultrasonic cleaning

Ultrasonic cleaning is to introduce ultrasonic vibration into the cleaning solution, and the vibration propagates in the cleaning solution to produce ultrasonic cavitation. When the frequency and intensity of ultrasonic vibration reach a certain appropriate level, a sufficient number of cavities are formed continuously, and then they are continuously closed. When the cavity on the surface of the workpiece is closed, a strong impact force can be formed to wash away the oil, so as to achieve the cleaning effect. Ultrasonic cleaning is suitable for removing oil from inner holes and parts with complex shapes.

4. High-pressure water jet cleaning technology

High-pressure water jet cleaning technology is a high-tech cleaning technology that has emerged internationally in recent years. High-pressure water jet cleaning has the advantages of strong adaptability, good quality, fast speed, low cost, and no environmental pollution.

5. Other cleaning methods

Other cleaning methods include electrochemical cleaning, trichloroethylene cleaning, and so on.

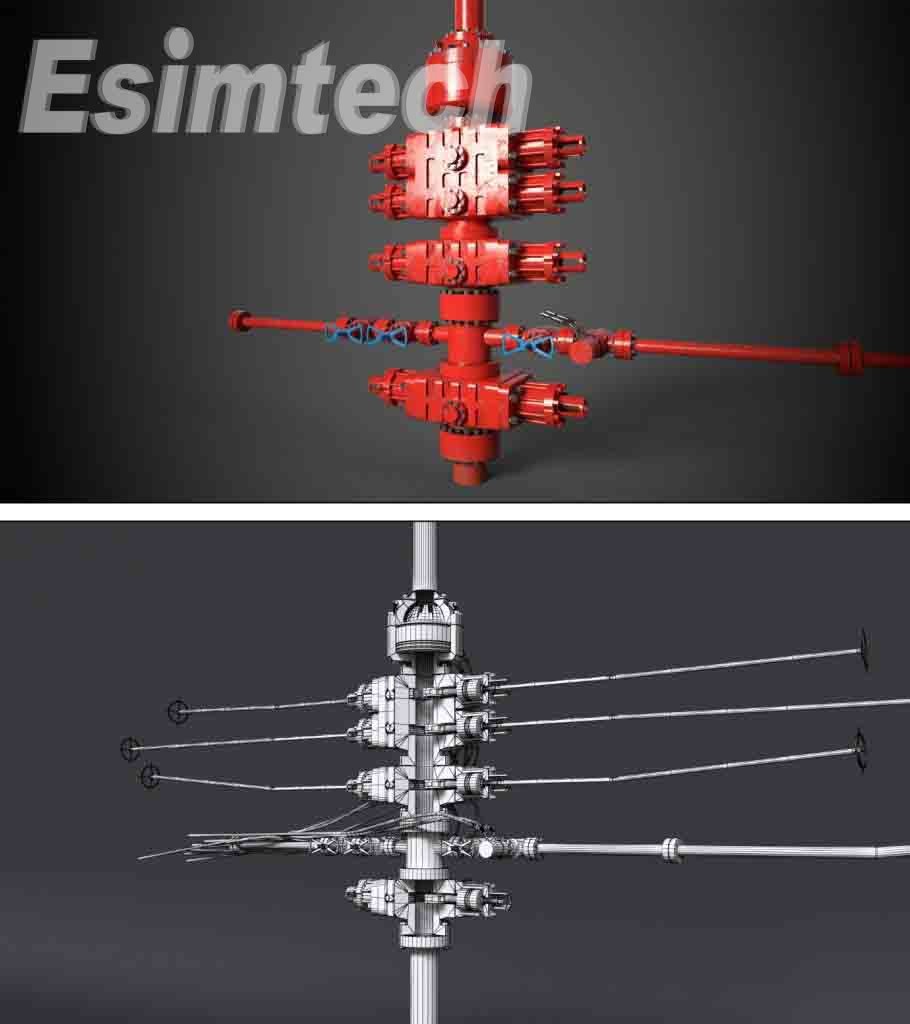

Esimtech is an enterprise focusing on providing simulation training for the whole workflow of the oil and gas industry. We welcome customers at home and abroad to consult us at any time about products and relevant knowledge. Of course, we can also provide customized products and services to you according to your needs.