Why Use Subsea Well Intervention Techniques

As the oil industry ventures into deeper waters and more difficult conditions, the value of efficient and effective well intervention techniques becomes increasingly obvious. This article explores the fundamentals of subsea well intervention, its significance, key methods, technological advancements shaping its future and how simulation technology used in optimizing subsea well intervention techniques.

Understanding Subsea Well Intervention

Subsea well intervention is a set of techniques and activities designed to maintain, repair, and optimize subsea oil and gas wells without the requirement for a full well intervention rig mobilization. Unlike traditional well interventions, which usually entail accessing wells from platforms or drilling rigs, subsea interventions are carried out remotely from surface vessels using specialized equipment.

Significance of Subsea Well Intervention

| Benefit | Description |

| Extended Well Life | Subsea intervention allows for repairs, replacements, and stimulation techniques to be deployed on existing wells. This can significantly extend the productive life of a well, maximizing resource extraction and delaying the need for expensive new wells. |

| Cost-Effective | Compared to deploying a drilling rig for well access, subsea intervention utilizes smaller, more specialized vessels. This reduces operational costs and makes production from marginal fields more feasible. |

| Improved Production | Intervention techniques can address issues like blockages or formation damage, ultimately leading to increased oil and gas flow rates. |

| Access to Stranded Reserves | Subsea intervention allows for reaching and extracting hydrocarbons from reservoirs that traditional drilling methods cannot access due to depth or location. |

| Enhanced Safety | Subsea intervention offers a safer alternative to traditional well access methods, as it eliminates the need for personnel to be stationed on a platform directly above the well. |

Key Methods of Subsea Well Intervention

These methods are crucial for ensuring the integrity, productivity, and safety of subsea assets.

1. Wireline Intervention

Description: Wireline intervention is the use of a cable, or wireline, to transport tools and equipment downhole for a variety of intervention operations.

Applications: Logging, perforating, inserting plugs, deploying downhole instruments, sampling, and running well diagnostics.

Advantages: Provides precise control and real-time data acquisition, allowing for targeted interventions and well performance evaluation.

2. Coiled Tubing Intervention

Description: Coiled tubing intervention employs a continuous reel of tubing to convey tools, fluids, and equipment into the wellbore.

Applications: Cleanouts, acid stimulation, hydraulic fracturing, sand control, plug setting, and wellbore remediation.

Advantages: Enables continuous operations without the need for multiple pipe connections, minimizing rig-up time and enhancing operational efficiency.

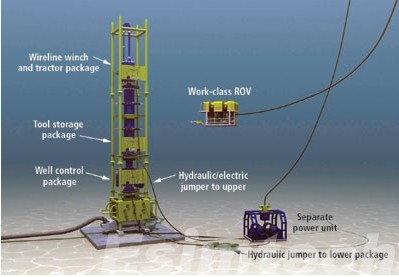

3. Remotely Operated Vehicles (ROVs)

Description: ROVs are unmanned underwater vehicles equipped with manipulator arms, cameras, and sensors, controlled from the surface vessel.

Applications: Wellhead maintenance, valve operations, intervention tool deployment, subsea equipment installation, and visual inspections.

Advantages: Facilitates intervention operations in deepwater and hazardous environments, reduces human exposure to risks, and provides high-resolution imaging for detailed assessments.

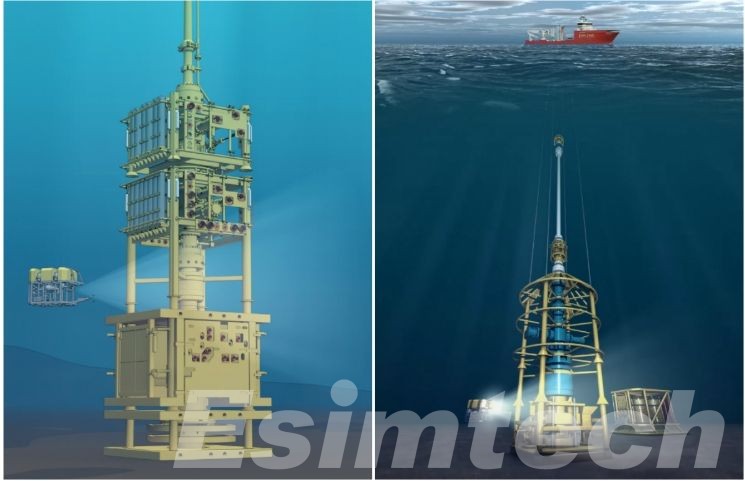

4. Subsea Hydraulic Workover (HWO) Systems

Description: HWO systems are specially designed to perform more extensive interventions, such as completions, workovers, and wellhead repairs, using hydraulic power.

Applications: Tubing and casing repairs, wellhead maintenance, equipment installation, and conductor cutting.

Advantages: Allows for larger-scale interventions without the need for rig mobilization, reducing costs and downtime associated with traditional well interventions.

5. Intervention Modules and Systems

Description: Intervention modules and systems are modular units designed to be installed on existing subsea infrastructure, enabling various intervention operations.

Applications: Hydraulic intervention, chemical injection, gas lift optimization, scale removal, and wellhead monitoring.

Advantages: Enhances the flexibility and versatility of subsea interventions by providing customizable solutions tailored to specific well conditions and requirements.

6. Subsea Pumping and Compression Systems

Description: Subsea pumping and compression systems are installed on the seabed to boost production rates and mitigate flow assurance challenges.

Applications: Gas and liquid boosting, artificial lift, hydrate prevention, and reservoir pressure maintenance.

Advantages: Improves hydrocarbon recovery from low-pressure reservoirs, extends field life, and minimizes the need for surface facilities, reducing operational costs and environmental footprint.

7. Through-Tubing Intervention Tools

Description: Through-tubing intervention tools are specially designed to access and perform interventions through existing tubing or casing strings.

Applications: Fishing operations, wellbore cleanouts, setting plugs and packers, and selective perforating.

Advantages: Minimizes the need for wellbore interventions and sidetracks, preserving well integrity and maximizing production efficiency.

Technological Advancements and Future Trends of Subsea Well Intervention

1. Robotics and Autonomous Systems

One of the most significant trends in subsea well intervention is the integration of robotics and autonomous systems. Remotely Operated Vehicles (ROVs) equipped with advanced manipulator arms and sensory capabilities are increasingly used for a wide range of intervention tasks, including wellhead maintenance, valve operations, and subsea equipment installation. Furthermore, the development of Autonomous Underwater Vehicles (AUVs) promises to revolutionize intervention operations by enabling autonomous, unmanned missions in deep and challenging environments.

2. Intelligent Intervention Tools

The use of subsea interventions is changing due to the introduction of intelligent intervention instruments that have sensors, actuators, and data processing capabilities. These devices have the ability to collect data in real time from downhole conditions, analyze it locally, and make decisions on their own to maximize intervention tactics. Intelligent downhole gauges for reservoir monitoring, smart plugs for selective zonal isolation, and adaptive control systems for exact fluid placement during stimulation treatments are a few examples.

3. Subsea Compression and Pumping Systems

Subsea compression and pumping systems represent a paradigm shift in subsea intervention, enabling operators to boost production rates and extend the life of mature fields without the need for costly surface facilities. These systems, installed on the seabed near the wellhead, compress or pump hydrocarbons directly from the reservoir to the processing facilities, overcoming flow assurance challenges and maximizing recovery from low-pressure reservoirs.

4. Digital Twins and Predictive Analytics

The integration of digital twin technology with subsea intervention operations offers unprecedented insights into well performance and integrity. By creating virtual replicas of subsea assets and simulating various operating scenarios, operators can optimize intervention strategies, predict equipment failures, and minimize downtime. Moreover, advanced analytics techniques, such as machine learning and predictive modeling, enable early detection of potential issues and proactive maintenance planning, enhancing overall operational efficiency and reliability.

5. Subsea Electric Power and Control Systems

The adoption of subsea electric power and control systems is revolutionizing subsea intervention operations by providing reliable, high-power electrical supply and remote control capabilities on the seabed. These systems eliminate the need for hydraulic or pneumatic umbilicals, reducing complexity, maintenance costs, and environmental footprint. Additionally, electric actuation enables precise control of subsea valves, chokes, and other equipment, enhancing intervention accuracy and efficiency.

6. Environmental Monitoring and Mitigation Technologies

With increasing scrutiny on environmental sustainability, the development of environmental monitoring and mitigation technology is gaining traction in subsea intervention. Leaks, spills, and other environmental dangers can be detected in real time using subsea sensors and monitoring systems, allowing for fast response and mitigation. Furthermore, innovative materials and coatings are being developed to reduce the environmental impact of subsea infrastructure and equipment while maintaining compliance with strict laws and industry standards.

Future Trends

Looking ahead, the future of subsea well intervention is poised for further advancements driven by technological innovation, industry collaboration, and evolving market dynamics.

Continued integration of robotics, autonomy, and artificial intelligence to enhance intervention capabilities and efficiency.

Development of advanced materials, coatings, and corrosion-resistant alloys for prolonged subsea equipment lifespan and reliability.

Expansion of subsea electrification and renewable energy solutions to reduce carbon footprint and operational costs.

Integration of blockchain technology for secure data management, supply chain optimization, and regulatory compliance.

Collaboration between industry stakeholders, academia, and research institutions to address emerging challenges and unlock new opportunities in subsea intervention.

How Simulation Technology Used in Subsea Well Intervention

1. Planning and Design

Simulation software allows engineers and operators to create detailed models of subsea wells, equipment, and surrounding environments. These models can be used to simulate different intervention scenarios, evaluate potential risks, and optimize intervention strategies before execution. By running simulations, operators can identify potential issues and plan interventions more effectively, ensuring safe and efficient operations.

2. Training and Skills Development

Simulation technology provides a realistic and immersive training environment for personnel involved in subsea well intervention. Trainees can practice operating intervention equipment, performing tasks such as wellhead maintenance, valve operations, and tool deployment in a controlled setting. This hands-on training helps improve competency, decision-making, and response to emergency situations, enhancing overall safety and performance.

3. Equipment Testing and Validation

Oil simulation tools allow operators to test and certify subsea intervention equipment and tools in virtual settings before deploying them in the field. This enables for the evaluation of equipment performance, usefulness, and suitability for specific well circumstances. By identifying possible faults early on, operators can reduce the chance of equipment failure and assure consistent operation during actual interventions.

4. Real-Time Decision Support

Some advanced well intervention simulators offer real-time data integration and decision support capabilities during intervention operations. By combining real-time sensor data from subsea assets with predictive models and simulations, operators can make informed decisions and optimize intervention strategies on the fly. This enables proactive problem-solving, mitigates risks, and maximizes operational efficiency during interventions.

5. Post-Intervention Analysis

Simulation technology allows for post-intervention analysis and evaluation of intervention performance. Operators can compare actual intervention results to simulated scenarios, identify areas for improvement, and document lessons learned for future operations. This retrospective study helps to refine intervention tactics, improve operational procedures, and drive continual progress in subsea intervention activities.

Conclusion

Subsea well intervention is crucial for ensuring the safety, integrity, and productivity of subsea oil and gas wells. In an increasingly complex and demanding environment, operators can overcome hurdles and realize the full potential of offshore hydrocarbon resources by employing sophisticated technologies and novel procedures. Subsea well intervention relies heavily on simulation technology, which provides a virtual environment for planning, training, and improving intervention operations.