The Role of Downhole Sensors in Measurement While Drilling (MWD)

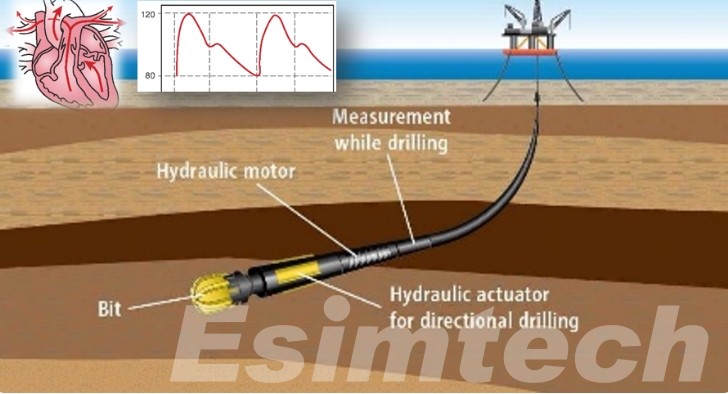

Today’s oil and gas drilling involves real-time decision-making while emphasizing precision and productivity to minimize expenses and risk. Among these technologies, Measurement While Drilling (MWD) has become one of the primary technologies used, relying on the use of downhole sensors. The remaining sensors, located on the bottom hole assembly (BHA), receive and store vital formation and drilling parameters. MWD drilling would not be able to provide the necessary information to optimally drill and drill safely without the respective sensors.

How Downhole Sensors Enable MWD Drilling

Downhole sensors serve as the MWD drilling ecosystem core. Their functionality involves the conversion of plastered geological and physical parameters along the wellbore to binary information that can be sent offshore. They must also withstand the extreme mechanical stress, vibration, and other high-pressure, high-temperature (HPHT) conditions.

The combination of sensors and MWD drilling components provides the user with real-time information without having to pause drilling and perform wireline logging, greatly enhancing control and safety to the overall drilling procedure.

Types of Downhole Sensors Used in MWD Drilling

| Sensor Type | Primary Function | Key Application in MWD |

| Directional Sensors (accelerometers, magnetometers) | Measure inclination, azimuth, and toolface orientation | Provide real-time directional data for trajectory control in directional and horizontal drilling |

| Pressure Sensors | Monitor borehole and annular pressures | Detect kicks, fluid losses, and ensure wellbore stability |

| Temperature Sensors | Record downhole temperatures | Protect tools from overheating and support reservoir characterization |

| Gamma Ray Sensors | Measure natural gamma radiation | Distinguish lithology and correlate formations while drilling |

| Resistivity Sensors | Measure the electrical resistivity of formations | Identify hydrocarbon-bearing zones and guide geosteering |

| Vibration and Shock Sensors | Detect mechanical stress, shock, and vibration | Prevent tool damage and optimize drilling parameters |

| Torque and Weight-on-Bit Sensors | Track torque and axial loads on the drill bit | Improve drilling efficiency and extend bit life |

Key Functions of Downhole Sensors in MWD Drilling

1. Directional Surveying and Well Path Control

Remember the most crucial aspects of the downhole sensors in MWD drilling and the data recorded. What devices do the estimators and their servants use to measure inclinations, azimuth, and the tool face and the physical position of the tool in the vertical plane. Correct the angle of the tool to the planned path and correct the angle of the drilling. Great precision is needed to avoid dishing from the planned path. This is very needed in horizontal and directional wells.

2. Formation Evaluation and Reservoir Navigation

Downhole sensors also are central in the formation evaluation sensor measurement. The Resistivity sensors look at the surrounded rocks. While gamma ray devices measure a ray which is visible and not visible. This helps the operators to recognize different types of rock formations. This helps to notice and identify the rock formation that has a lot of light crude and oil. This system helps to easily geosteer where enough productive reservoir layers are present with the maximum recovery. Thus minimal capital is wasted in useless drilling.

3. Monitoring of Wellbore Conditions

The other critical activities of the downhole sensors are the wellbore condition monitoring activities. Pressure sensors measure annular and borehole pressures and provide early warnings for kicks, fluid losses, or wellbore instability. Temperature sensors assist in the protection of sensitive electronic equipment and provide more understanding of the reservoir attributes by measuring downhole temperatures. This also helps in shift continuous monitoring activities which enhances safety and reduces the chances of catastrophic drilling accidents.

4. Drilling Performance Optimization

The set of downhole sensors which measure vibration, shock, downhole torque and weight on bit assist in the maximization of drilling efficiency. Operators can modify drilling parameters such as rotation speed, weight distribution, and fluid circulation in near real-time provided those parameters are set in the perform level. This contributes to more effective operations by extending the life of the bit, reducing equipment failure, and reducing non-productive time.

5. Data Telemetry and Real-Time Decision Making

Downhole sensor functions include measurements and arbitrary data collection activities such as data compression and remote data collection through the mud-pulse system and electromagnetic and wired-pipe telemetry systems. Such systems compress the data into bit streams and send the data as packets to the surface. The ability to send peices of data such streams can help in real time decision making and help improve the time wasted in logging procedures. Having access to the downhole information in real time helps the operators to make changes inpromptu and therefore enhances safety and efficiencies in the operations.

How Simulations are Used for Downhole Sensors in MWD Drilling

Using real tools for testing in real wells is both expensive and dangerous. That is the main reason why the testing of MWD drilling is done through the use of virtual simulations. Oil ans gas simulations are valuable works, and they help engineers and drilling operators to predicate, asses and analyze the tools and their possible performance in the field under real-world conditions.

Simulating Extreme Downhole Environments

The downhole sensors, during MWD drilling, need to endure incredible punishment, such as temperature and mechanical, as well as pressure, and being “pushed” to their limits, downhole environment simulations would find an idealized wellbore environment, allowing engineers to easily replicate and assess such conditions. This, in turn, allows the evaluation of the sensors in regards to their accuracy, reliability and durability. Identifying weaknesses during the design stages greatly mitigates the chances of failure of the system during actual drilling activities, and so this approach, in turn, makes use of the design weaknesses to prevent failure during operation, ease of function.

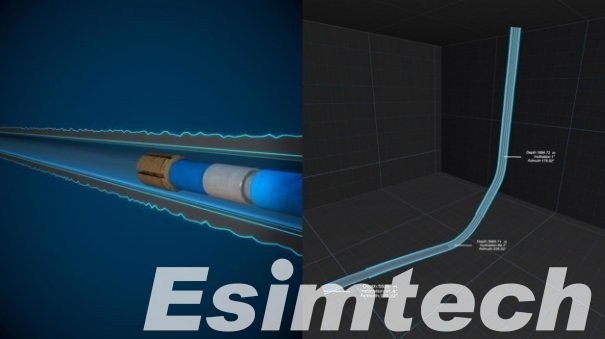

Virtual Testing of Sensor Accuracy

The endless and costly need to build “real-world” prototypes has been mitigated by the advent of simulation technology. Prototypes are no longer needed, as they can easily be replaced by the recently developed tools. This can be seen in the use of directional sensors, accelerometers and magnetometers that are sued to traverse wellbore trajectories, measuring angle of inclination and azimuth. In the same manner, the validation of gamma ray and resistivity sensors are made easier by comparing them to the synthetic formation values they are meant to provide.

Modeling Drilling Dynamics and Sensor Responses

During the drilling process, the drills and the formations work together and create vibrations, perturbations in the torque, and other dynamic mechanical conditions. Through drilling simulations, it is possible to predict with reasonable outcomes the ways in which the drills and the formations would interact. Such predictive approaches are useful in understanding the interaction, which engineers would then use to adjust the calibration and the protective mechanisms to extend the lifespan of the sensors. This is extremely pertinent with regard to the shock and the vibrations sensors, which are in need of succor and can provide the most pertinent and useful data, despite being under the most severe stress.

Enhancing Telemetry System Development

Telemetry is important for MWD drilling because it is what enables the sending of the sensors data to the surface. During the process of drilling, models are used to evaluate the sending of data in the forms of mixed pulses, electromagnetic pulses, and data sent through wires and the use of drill pipes. These models ensure that the data is greatly enough so that the sensors can be used without delays and distortion even under harsh conditions. These conditions are referred to as wells which are completely adverse.

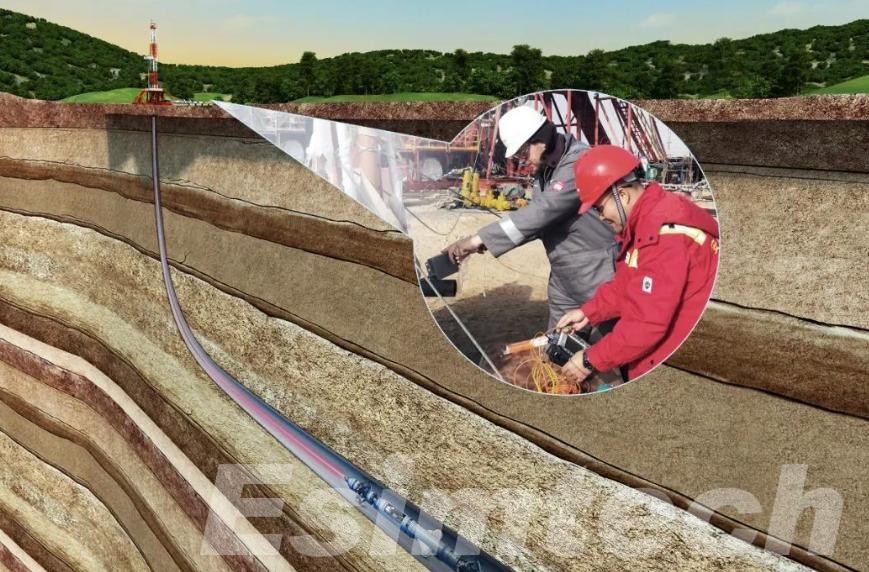

Training and Operational Simulations

Apart from the development of the tools used, there is increasing use of drilling simulation training for the operation personnel and also for planning the operations. Drilling operators are able to visualize in the form of sensors and data being monitored and what the position of the drill is down the hole. This also enables them to simulate the conditions in which the hole would be and thus prepares them for the data which would be available from real-life sensor situations. This helps them to be more agile in the case of the unexpected changes in the wellbore.

Challenges Faced by Downhole Sensors in MWD Drilling

| Challenge | Description | Impact on Operations |

| High-Pressure, High-Temperature (HPHT) Conditions | Sensors must withstand extreme temperatures (up to 200°C or more) and pressures exceeding 20,000 psi | Reduces sensor lifespan and reliability |

| Mechanical Stress and Vibration | Constant shock, vibration, and torsional forces affect sensor stability | Leads to calibration drift, data inaccuracy, or tool failure |

| Limited Telemetry Bandwidth | Mud-pulse and EM telemetry have restricted data transmission speeds | Limits the amount of real-time data available at surface |

| Power Supply Limitations | Downhole tools rely on batteries or turbine generators | Restricts continuous operation and sensor deployment time |

| Data Overload and Interpretation | Vast amounts of sensor data must be processed and interpreted rapidly | Requires advanced analytics and skilled personnel |

| High Cost of Development and Maintenance | Sophisticated sensors are expensive to design, deploy, and repair | Increases overall drilling project costs |

| Corrosive and Abrasive Environments | Drilling fluids and formations can damage sensor housings | Shortens tool life and increases maintenance frequency |

Future Direction of Downhole Sensors in Measurement While Drilling

The future direction of downhole sensors points toward greater durability, faster data transmission, smarter analytics, and deeper integration with automated drilling systems.

- Advancements in High-Pressure High-Temperature (HPHT) Endurance

Downhole sensors will in the future be designed to survive more extreme downhole environments. Due to strides in materials science and the development of high temperature electronics, sensors will be able to operate in a greater historical, and ultra deep pressure, surpassing the 200-degree centigrade and deep conditions. This will increase retention periods, and reduce failure rates, thus extending the lifespan of the tools. It will also enable drilling in ultra deep waters and unconventional drilling.

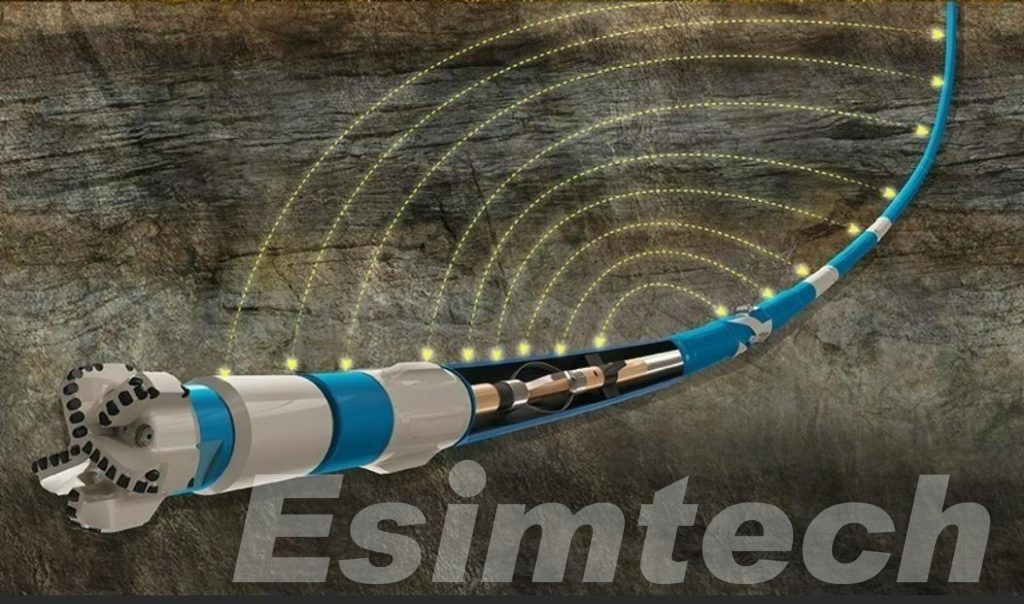

- Miniaturization and Multi-Sensor Integration

Miniaturization as a direction in sensor technology is also of great importance. Compact configurations will enable numerous sensors to be housed in the bottom hole assembly with no increase in the size or complexity of the tool. Multi-sensor systems, enhancing data and efficiency, will offer a more rounded perspective of downhole environments by integrating direction, gamma ray, resistivity, and vibration measurements in a single module.

- Enhanced Data Telemetry and Connectivity

Telemetry as a whole is expected to see rapid advancements as well. Instead or adding to mud pulse telemetry, which is traditionally used, wired drill pipes and sophisticated electromagnetic systems are believed to offer lower latency and higher bandwidth. These technologies provide downhole sensors the ability to transmit datasets in real time, which will enable more effective and faster geosteering, thus facilitating quicker decision making.

- Smarter Analytics and Artificial Intelligence Integration

The future of sensors will include MWD drilling systems that not only transmit measurements but perform downhole processing and predictive analytics. Machine learning will further enhance and AI will integrate more deeply into analyzing sensors data. Predictive analytics will allow preliminary insight and warning of downhole problems that could optimize drilling and automate parameter decisions for even higher level of safety and efficiency.

- Digital Twin and Predictive Maintenance

The concept of digital twins, virtual models of physical assets, can be extend to downhole sensors. Each one can be equipped with a learning digital twin that predicts and prevents failures, streamlining proactive maintenance which increases both reliability and availability while decreasing upkeep.

- Integration with Automated and Remote Drilling Systems

The future of drilling is increasingly automated, and downhole sensors will be a crucial enabler of this transition. As automation expands, sensors will provide the precise and reliable data required for closed-loop drilling systems. Combined with remote operations centers, this integration will support fully automated well construction, minimizing human intervention in hazardous environments.

Summary

The cornerstone of Measurement While Drilling technology utilization is downhole sensors, which facilitate directional control, formation evaluation, and real-time wellbore surveillance. Regarding process efficiency, risk minimization and improved understanding of geological reservoirs, their contribution is essential. It is certain that the evolution of the civilization extending in the technology field will allow the development of durable, intelligent and data rich sensors. This will change the utility of MWD drilling in the drilling industry to a vital one, ensuring the process is safe and economical.