Advancements in Subsea Technologies for Efficient Oil Exploration

Subsea technologies continue to advance, transforming the oil and gas sector by allowing for more efficient and effective exploration and extraction procedures. The challenges of operating in deep-sea environments have driven ongoing innovation, resulting in the development of cutting-edge technology that improve the capabilities and safety of offshore oil exploration activities. In this article, we will explore some of the latest advancements in subsea technologies that are transforming the landscape of oil exploration and how simulation is used for enhancing oil exploration in conjunction with subsea technologies.

Latest Advancements in Subsea Technologies for Enhancing Oil Exploration

1. Autonomous Underwater Vehicles (AUVs)

Enhanced Surveying

High-Resolution Imaging: AUVs equipped with advanced imaging systems, such as multibeam sonars and high-definition cameras, provide detailed and high-resolution surveys of the seafloor. This enhances the accuracy of geological assessments.

Autonomous Navigation: AUVs with improved autonomous navigation capabilities can efficiently cover large areas, conducting surveys in a more time-effective manner than traditional methods.

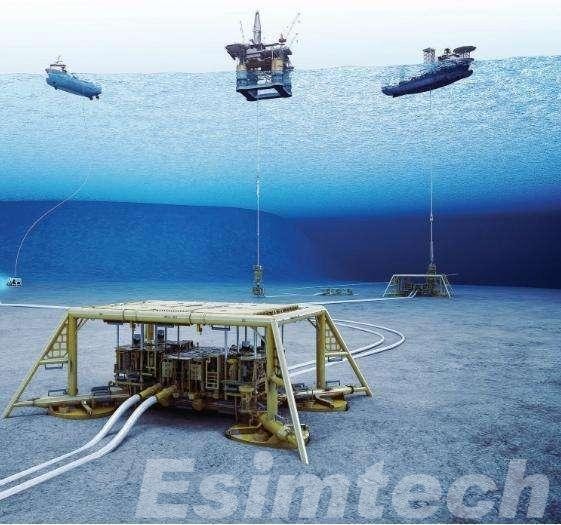

2. Remote Operated Vehicles (ROVs)

Intelligent Manipulation

Advanced Manipulator Arms: ROVs now feature more advanced manipulator arms with increased dexterity and precision. This allows for intricate tasks such as valve operation, equipment installation, and sample collection with improved efficiency.

Real-Time Control Systems: Enhanced real-time control systems enable operators to remotely manipulate ROVs with greater accuracy, providing immediate responses to changing subsea conditions.

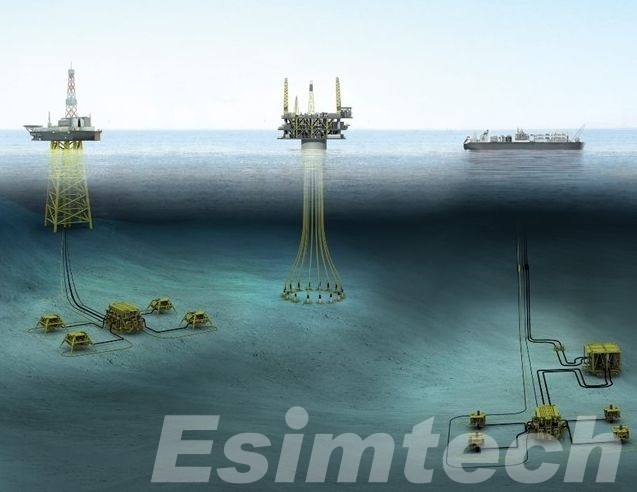

3. Subsea Processing Systems

On-The-Fly Processing

Inline Processing: Subsea processing systems have evolved to perform essential functions such as separation, boosting, and compression directly on the seafloor. This on-the-fly processing reduces the need for transporting fluids to the surface, optimizing production.

Improved Fluid Handling: Advanced subsea processing systems can handle a variety of reservoir fluids, including those with high levels of contaminants, contributing to increased recovery rates.

4. Real-Time Monitoring and Data Analytics

Integrated Sensor Networks

Sensor Fusion: Subsea installations now incorporate integrated sensor networks that utilize sensor fusion techniques. This enables the simultaneous monitoring of various parameters such as pressure, temperature, and flow, providing a comprehensive understanding of subsea conditions.

Data Analytics Platforms: Advanced data analytics platforms process real-time data from subsea sensors, offering insights into reservoir behavior, equipment health, and potential issues. This facilitates predictive maintenance and decision-making.

5. Subsea Power Distribution

Electrical Subsea Technologies

Subsea Power Grids: The development of subsea power distribution systems allows for the transmission of electrical power to subsea equipment. This eliminates the need for hydraulic or pneumatic systems, enhancing reliability and reducing maintenance requirements.

Advanced Cable Technology: Innovations in subsea cable technology enable the efficient transmission of power over long distances, supporting the electrification of subsea installations.

6. Hybrid Riser Systems

Enhanced Riser Technology

Hybrid Flexible Risers: Advances in riser technology include the development of hybrid flexible risers that combine the benefits of steel and flexible materials. These risers offer improved fatigue resistance and reliability in challenging subsea conditions.

Increased Water Depth Capability: Enhanced riser systems support oil exploration in greater water depths, expanding the reach of subsea exploration activities.

7. Drones for Subsea Inspection

Underwater Drone Technology

Remotely Operated Drones: Drones designed for subsea inspections are becoming more sophisticated, offering real-time video feeds and high-resolution imaging. They can navigate complex subsea structures, providing visual assessments for maintenance and integrity checks.

Machine Learning Integration: Some underwater drones now integrate machine learning algorithms to analyze images and identify potential issues, enabling efficient decision-making for maintenance and repair activities.

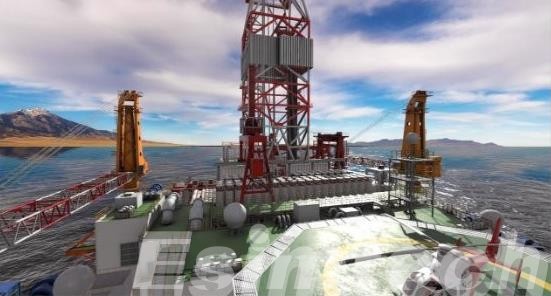

8. Deepwater Drilling Technologies

Advanced Drilling Equipment

Managed Pressure Drilling (MPD): MPD technologies allow for precise control of wellbore pressure, enhancing safety and enabling drilling in challenging formations. This technology minimizes the risk of kicks and wellbore instability.

Dual Gradient Drilling: Dual gradient drilling systems are designed to optimize drilling operations in deepwater environments. These systems control wellbore pressure by using two different drilling fluids, improving stability and reducing the likelihood of well control incidents.

Simulation technology plays a crucial role in optimizing and advancing oil exploration processes, especially in the context of subsea technologies. Due to the complex and hard conditions of subsea environments, simulation is a useful tool for planning, testing, and improving many aspects of oil exploration.

| Description | Advancements | Benefits |

| Simulating reservoir conditions. | Advanced reservoir simulation software. | Prediction of reservoir performance. Optimal well placement strategies. |

| Designing and testing subsea equipment. | 3D modeling and simulation software. | Identifying design flaws. Optimizing equipment performance. |

| Simulating drilling operations. | Realistic drilling simulations. | Improved drilling efficiency. Risk reduction in unexpected challenges. |

| Simulating fluid flow in subsea pipelines. | Computational Fluid Dynamics (CFD) simulations. | Identifying flow issues.Optimizing pipeline design. |

| Planning for and responding to emergencies. | Real-time dynamic emergency practice simulation trainning. | Enhanced preparedness.Minimized environmental impact. |

| Simulation of integrated control systems. | Digital twins and advanced control algorithms. | Improved system reliability.Enhanced overall operational efficiency. |

| Simulation for drilling personnel training. | Virtual reality (VR) and augmented reality (AR) technologies. | Risk-free skill development. Enhanced decision-making in real-world scenarios. |

Conclusion

As the oil and gas sector expands into deeper and more difficult offshore locations, the most recent advances in subsea technologies are critical to overcoming technical challenges of deepwater oil exploration and assuring long-term, efficient operation. These advances improve not just the precision and efficiency of exploration procedures, but also help to reduce the environmental impact of offshore activities.

Simulation technology, when combined with subsea technologies, provides a complete and efficient method for oil exploration. These models not only enhance exploration processes, but also help to improve safety, cost-effectiveness, and environmental sustainability in tough underwater environments. As technology advances, the combination of simulation and subsea technologies is projected to improve the oil and gas industry’s ability to uncover significant resources beneath the ocean floor.