What are the Challenges of Deepwater Oil and Gas Exploration

Deepwater oil and gas exploration, while promising to unlock massive energy resources, is not without serious hurdles. The quest for hydrocarbons in deep-sea environments necessitates cutting-edge technology, severe safety precautions, and environmental concerns. This article delves into the significant challenges faced by oil and gas exploration in its quest for resources beneath the ocean depths, how to address the challenges, and how simulation technology is used in deepwater oil and gas exploration.

Key Challenges Faced by Deepwater Oil and Gas Exploration

1. Extreme Operating Conditions

Deepwater exploration frequently requires operating in harsh conditions, such as high pressures and low temperatures. The equipment and materials utilized must resist these severe environments, which creates engineering hurdles in the design and construction of subsea infrastructure and drilling equipment.

2. Technological Complexity

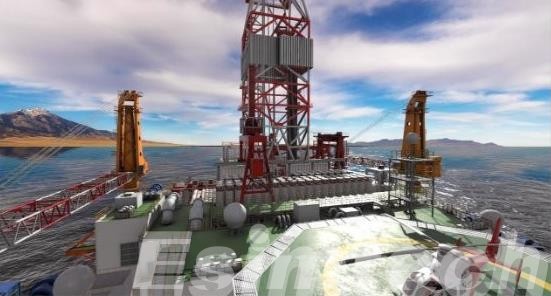

The technological complexity of deepwater exploration is a significant hurdle. Developing and installing sophisticated equipment like remotely operated vehicles (ROVs), innovative drilling rigs, and subsea production systems necessitates significant R&D investments. Technological failures can result in costly delays and safety concerns.

3. Safety and Well Control

Deepwater operations require the highest level of safety. The industry faces the problem of guaranteeing worker safety, preventing blowouts, and developing effective well control techniques. The depth and complexity of deepwater wells increase the dangers connected with drilling, necessitating ongoing awareness and preparedness.

4. Cost Considerations

Deepwater exploration incurs significant costs, from the design and building of specialized platforms to the deployment of modern technologies. Deepwater projects' capital expenditures can be a barrier, particularly during times of economic instability and fluctuating oil prices.

5. Environmental Impact and Regulation

The environmental impact of deepwater drilling is a significant concern. To prevent accidents, spill response and containment measures must be implemented. Stringent environmental requirements necessitate detailed impact assessments and adherence to best practices, which add complexity and cost to deepwater projects.

6. Resource Uncertainty

Deepwater exploration includes tremendous uncertainty about the presence and accessibility of hydrocarbon reservoirs. Seismic surveys give useful data, but interpreting subsurface structures is intrinsically difficult. Drilling in unfamiliar territories increases the chance of not discovering economically viable reserves.

7. Logistics and Infrastructure

Deepwater operations entail logistical hurdles. Personnel, equipment, and supplies must be transported to offshore sites with meticulous preparation. Deepwater exploration infrastructure requires strategic coordination and resource management.

8. Human Resource Challenges

Deepwater operations require a highly skilled crew because of their specialized nature. Recruiting and maintaining qualified workers with knowledge of deepwater technologies and safety measures is a constant challenge. Training programs and knowledge transfer initiatives are critical to closing the human resource gap.

9. Political and Geopolitical Factors

Deepwater projects are frequently located in places fraught with political and geopolitical uncertainty. Regulatory changes, jurisdictional disputes, and variations in geopolitical dynamics can all have an impact on deepwater exploration projects' sustainability and stability.

How to Address the Challenges in Deepwater Oil and Gas Exploration

1. Invest in Research and Development

Continued investment in R&D is critical for creating cutting-edge technologies that can endure the harsh conditions of deepwater exploration. This includes advances in materials, subsea systems, and drilling technologies that improve efficiency, dependability, and safety.

2. Enhance Safety Measures

Rigorous safety measures are crucial in deepwater operations. Companies should invest in state-of-the-art safety technologies, conduct regular training programs for personnel, and establish comprehensive emergency response plans. Regular drills and simulations can improve preparedness for potential incidents.

3. Improve Well Control Technologies

Advances in well control technologies are imperative for preventing and mitigating blowouts in deepwater wells. Implementation of state-of-the-art blowout preventers, real-time monitoring systems, and well control procedures can significantly enhance the industry's ability to respond to unexpected events.

4. Optimize Cost Efficiency

Given the substantial costs associated with deepwater projects, optimizing cost efficiency is crucial. This involves adopting innovative project management strategies, exploring cost-sharing arrangements, and leveraging economies of scale. Continuous monitoring of project budgets and timelines is essential for financial sustainability.

5. Adhere to Environmental Best Practices

Strict adherence to environmental best practices and regulations is paramount. Conducting thorough environmental impact assessments (EIAs), employing advanced spill response technologies, and implementing measures to minimize ecological impact demonstrate a commitment to environmental stewardship.

6. Deploy Digital Technologies

The use of digital technologies such as data analytics, artificial intelligence, and machine learning can improve decision-making processes in deepwater exploration. These tools can evaluate large datasets, improve predictive modeling, and contribute to more efficient exploration tactics.

7. Collaborate on Industry Standards

Collaborative efforts within the industry to establish and adhere to standardized practices can contribute to safer and more sustainable deepwater exploration. Sharing best practices, lessons learned, and technological advancements fosters a collective approach to addressing common challenges.

8. Strengthen International Cooperation

Deepwater projects frequently require international cooperation. Transparent communication, information exchange, and collaboration with governments, regulatory organizations, and other stakeholders promote stability and allow for more efficient project implementation.

9. Invest in Human Capital

Developing and maintaining a skilled workforce is critical for the success of deepwater projects. Investing in training programs, knowledge transfer initiatives, and educational partnerships ensures that the industry has a qualified and capable workforce equipped to handle the complexities of deepwater exploration.

10. Diversify Energy Sources

Diversifying energy sources by integrating renewable energy initiatives with deepwater exploration can contribute to a more sustainable energy future. This approach can align with global efforts to transition towards cleaner energy solutions.

11. Plan for Geopolitical Risks

Companies working in deepwater areas must prepare for geopolitical uncertainty. This includes undertaking extensive risk assessments, staying current on geopolitical developments, and remaining flexible in project planning to adapt to changing political situations.

How Simulation Technology is Applied in the Deepwater Oil and Gas Exploration

1. Drilling Simulations

Simulation technology enables the simulation of realistic drilling scenarios within a virtual environment. This includes simulating different well architectures, reservoir conditions, and drilling techniques. Drilling and well control simulations help in training personnel, testing well control procedures, and optimizing drilling operations before actual deployment.

2. Reservoir Modeling

Advanced reservoir simulation technologies allow the production of 3D models that imitate the complicated subsurface conditions seen in deepwater reservoirs. These simulations aid in predicting reservoir behavior, improving well site, and calculating production potential. Engineers might try out alternative production procedures to enhance recovery.

3. Flow Assurance Simulations

Simulations are used to model fluid flow within subsea pipelines and production systems, predicting and mitigating flow assurance challenges. This includes analyzing the behavior of fluids under varying conditions, such as temperature and pressure changes, to prevent issues like hydrate formation and wax deposition.

4. Subsea Equipment Simulations

Simulating the performance of subsea equipment, such as blowout preventers (BOPs) and subsea control systems, helps in assessing their reliability and response under different conditions. This aids in the design and testing of robust equipment to ensure safety and well control during deepwater operations.

5. Dynamic Positioning Simulations

Deepwater drilling platforms and vessels frequently use dynamic positioning systems to maintain their location above wells. Simulation technology enables staff to be trained in dynamic positioning operations, test vessel responses to various environmental circumstances, and improve overall positioning system efficiency.

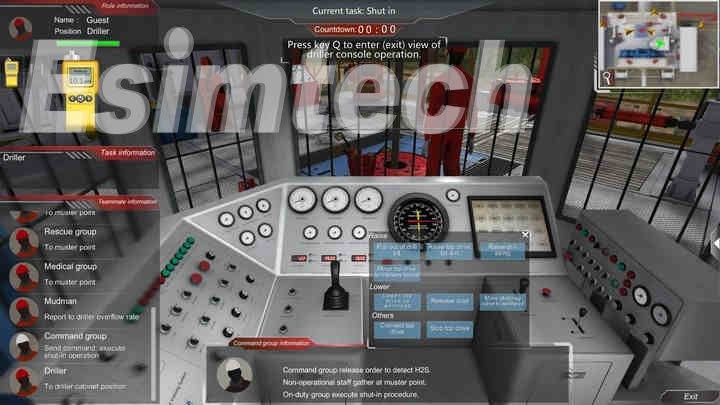

6. Emergency Response Training

Simulations are employed to train personnel for emergency response scenarios, such as well blowouts or equipment failures. These realistic simulations help enhance the preparedness of the workforce, enabling them to respond effectively to unexpected events and minimize the impact of emergencies.

7. Seismic Imaging and Interpretation

Simulations assist in seismic imaging and interpretation by replicating the behavior of acoustic waves in the subsurface. This aids geoscientists in testing different seismic survey parameters, improving the accuracy of subsurface imaging, and optimizing survey designs for better reservoir characterization.

8. Human-Machine Interface Simulations

Simulation technology is used to create and evaluate human-machine interfaces for drilling rigs and control centers. This ensures that operators can efficiently monitor and operate many systems, resulting in a more user-friendly and intuitive interface that improves overall operating efficiency.

9. Training for ROV Operations

Remotely Operated Vehicles (ROVs) are crucial in deepwater exploration for tasks such as subsea inspections and repairs. Simulation technology provides a realistic training environment for ROV operators, allowing them to practice maneuvers, navigation, and equipment manipulation in a controlled virtual setting.

10. Optimizing Production Strategies

Simulation models help in optimizing production strategies by considering factors such as well spacing, injection rates, and reservoir depletion. This enables operators to make informed decisions on reservoir management, enhancing overall recovery rates and maximizing the economic viability of deepwater projects.

11. Cost-Benefit Analysis

Simulations are used for conducting cost-benefit analyses by assessing different scenarios and variables. This helps decision-makers assess the economic feasibility of deepwater projects, optimize resource allocation, and find potential cost savings.

Conclusion

Addressing the challenges in deepwater oil and gas exploration necessitates a comprehensive, proactive approach. By combining technological innovation, severe safety measures, environmental responsibility, and strategic planning, the sector can traverse the difficulties of deepwater environments while assuring responsible and sustainable energy resource production.

Simulation technology is a powerful tool in deepwater oil and gas exploration, providing a virtual platform for testing, training, and optimizing numerous operational components. Simulations help to make deepwater exploration safer, more efficient, and economically sustainable.