Coiled Tubing Operation for Well Intervention and Stimulation Using Coiled Tubing

Coiled tubing operations are a vital part of modern oil and gas field management. This technology enables efficient well intervention and stimulation techniques, enhancing the productivity and life of wells. In this article, we will explore the mechanics of coiled tubing operations, key applications, stimulation techniques, essential tools, technologies, and the many advantages this method offers.

What is Coiled Tubing Well Intervention?

Coiled tubing well intervention involves using a continuous, flexible steel pipe spooled on a reel to perform various downhole operations. Unlike jointed pipes, coiled tubing does not require connections, allowing for faster deployment and retrieval. Coiled tubing interventions are used for well cleanouts, logging, perforating, stimulation, and more.

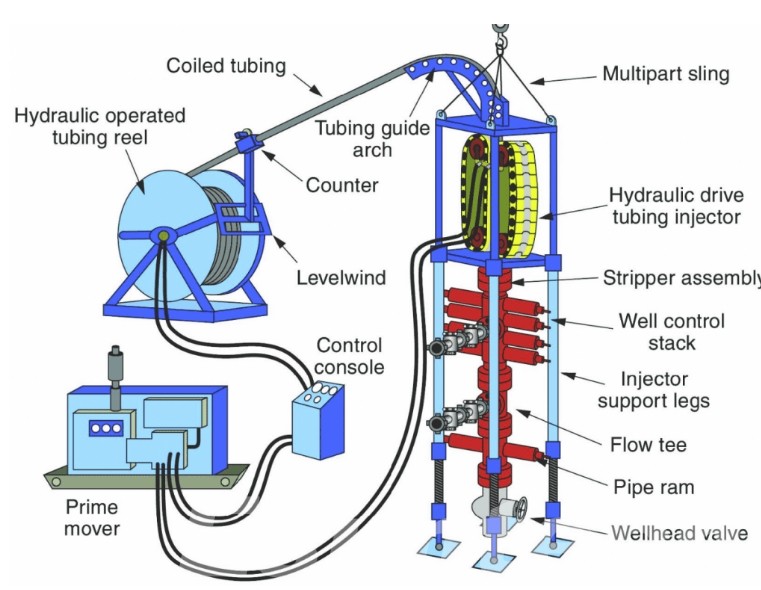

Basic Mechanics of Coiled Tubing operations

Operations related to coiled tubing interventions adhere to an efficiently engineered sequence in order to maximize efficiency and ensure safety.

An average operation typically begins with positioning of the coiled tubing unit at the wellhead and aligning its injector head to match that of the well's axis, then applying controlled pressure via hydraulic grippers within its injector head to feed a continuous tubing string into the wellbore while maintaining appropriate tension.

As tubing runs into the hole, fluids can be rapidly pumped through its hollow core at rates up to several barrels per minute. Due to its flexibility and lateral movement, tubing can easily traverse complex well paths such as horizontal sections and doglegs while maintaining depth control via surface measurements as well as downhole sensors that verify exact tool positioning.

Retrieval begins when the injector head's chain system reverses direction while maintaining constant back tension to avoid buckling of tubing retracted back onto a reel, with automated systems monitoring for fatigue or damage to ensure an orderly process. Real-time data transmitted over fiber optic lines or pressure pulses allows immediate adjustments of pump rates, tool activation rates, or trajectory as needed during retrieval operations.

Key applications

Coiled tubing serves as an efficient solution for numerous well intervention needs throughout the oil and gas industry, particularly wellbore cleanout, where its main use involves efficiently clearing away sand, scale, paraffin deposits or any debris hindering production.

Enhancing reservoir permeability and increasing hydrocarbon flow. Matrix acidizing and hydraulic fracturing treatments may also be used as stimulative therapies to achieve similar objectives.

Coiled tubing provides accurate delivery of downhole tools necessary for reservoir evaluation and targeted perforation in highly deviated or horizontal wells, even during perforating operations.

Additionally, fishing operations often enlist this tool for retrieving tools, broken equipment or any obstructions without needing an intensive workover rig setup.

Coiled tubing also plays a pivotal role in cementing and zonal isolation applications, where precise cement placement helps block off unwanted fluid entries or repair well integrity issues.

Nitrogen lifting and foam stimulation are popular practices used to unload liquid from gas wells and restore their production capabilities.

Coiled tubing offers unsurpassed efficiency for well maintenance and optimization in modern well environments, helping minimize downtime while increasing operational efficiencies - an indispensable advantage for modern well maintenance and optimization strategies.

What are Coiled Tubing Stimulation Techniques?

Coiled tubing has revolutionized well stimulation by enabling precise, targeted treatments that maximize reservoir performance while minimizing operational impact. These advanced techniques leverage the unique capabilities of continuous tubing to deliver fluids exactly where needed in the wellbore.

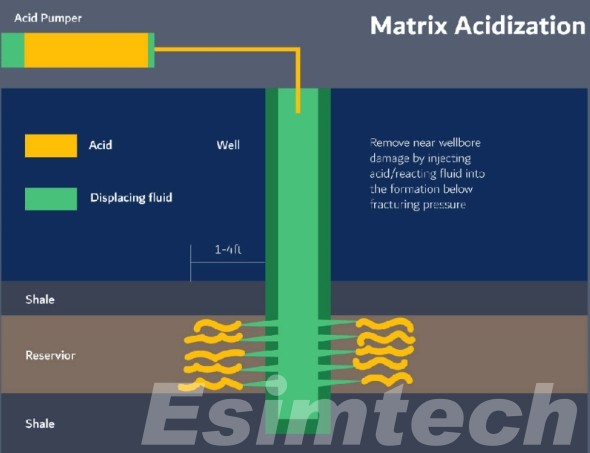

Precision Acid Stimulation Treatments

Acid stimulation through coiled tubing provides precise placement for both matrix and fracture treatments:

High-pressure acid injection helps dissolve formation damage near the wellbore and target specific zones using the coiled tubing's depth control system. Restoring natural permeability without creating new fractures - especially useful in carbonate formations

2)Fracture Acidizing:

High-pressure acid creates conductive channels in the formation, using viscous pads to initiate fractures before acid injection; maintaining more precise fracture geometry control than traditional methods, and is ideal for low permeability carbonate reservoirs.

Advanced Hydraulic Fracturing Applications

Coiled tubing enables innovative fracturing approaches:

1)Pinpoint Fracturing Technology:

Precision stimulation involves precisely stimulating individual zones within multilateral wells using packers or sand plugs for effective zonal isolation, with reduced fluid volume consumption relative to conventional fracturing methods and minimal disruption to productive zones adjacent.

2)Refracturing Operations:

Restores Production in Declining Wells Accesses Existing Perforations Without Additional Milling

Allows Selective Restimulation of Underperforming Intervals.

Combining diagnostics With Treatment Design Optimization for optimal treatment design.

Specialized Gas Well Stimulation Methods

1)Nitrogen Lift Systems:

Inert gas injection reduces hydrostatic pressure

Creates gas lift effect to unload liquid from wellbore

Particularly effective in low-pressure gas wells

Can be combined with foaming agents for enhanced recovery

2)Foam Stimulation Treatments:

Nitrogen-surfactant mixtures improve cleanout efficiency

Low-density fluids enable flowback in depleted wells

Provides superior proppant transport in fracture treatments

Reduces formation damage compared to conventional fluids

These coiled tubing stimulation techniques provide operators with unparalleled control over treatment placement and fluid dynamics. The ability to precisely target specific intervals while maintaining continuous well control results in more effective stimulation with reduced environmental impact and operational costs. Recent advancements in downhole monitoring tools and fluid chemistry have further enhanced the effectiveness of these methods, making coiled tubing stimulation a preferred choice for optimizing well performance across diverse reservoir conditions.

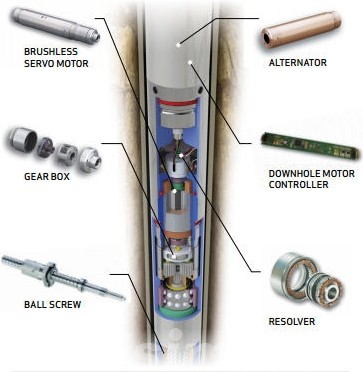

Key Tools & Technologies in Coiled Tubing Operations

Coiled tubing operations rely on various specialized tools and technologies to enhance efficiency, ensure safety, and optimize well intervention and stimulation tasks. Key components in these operations include:

- Coiled Tubing Reel: At the heart of any coiled tubing operation lies its core component - a reel storing and dispensing continuous steel tubing. This device allows it to be deployed and retrieved safely from wellbore environments under controlled conditions - an essential element in any coiled tubing unit.

- Injector Head: This hydraulic system is responsible for inserting coiled tubing into wellbores at high pressure using rollers or clamps, feeding the tubing into place at variable speeds depending on operational needs.

- Downhole Tools: A range of specialized tools is used in coiled tubing operations to perform various tasks, including:

Perforating Guns: These tools are used to create perforations in the well casing, allowing hydrocarbons to flow into the wellbore.

Packers: Used to isolate certain sections of the wellbore, packers help control fluid flow and pressure during interventions.

Pumps: Coiled tubing units are often equipped with high-pressure pumps to deliver fluids, such as acids, gels, or nitrogen, into the well for stimulation or cleaning.

- Control Systems and Real-Time Monitoring: Modern coiled tubing units feature advanced control panels that allow operators to monitor and control all aspects of the operation, including pressure, temperature, and fluid flow. Real-time monitoring technologies provide valuable data, helping to make informed decisions and ensure optimal results throughout the operation.

- Communication and Safety Systems: Integrated communication tools and safety systems, such as blowout preventers (BOPs) and pressure safety valves, are crucial for managing wellbore integrity and ensuring operational safety during coiled tubing interventions.

These tools and technologies combine to make coiled tubing a highly versatile and effective solution for a wide range of well intervention and stimulation activities.

Advantages of Coiled Tubing for Well Interventions

Coiled tubing technology offers numerous operational and economic benefits that make it the preferred choice for modern well intervention operations. These advantages stem from its unique continuous-pipe design and versatile deployment capabilities.

- Operational Efficiency

The continuous tubing design eliminates the need for pipe connections, enabling significantly faster rig-up and deployment compared to jointed pipe operations. A standard coiled tubing unit can be mobilized and operational within hours, reducing non-productive time. The system allows for simultaneous pumping while running in or pulling out of hole, a capability that dramatically improves operational efficiency. This continuous circulation feature is particularly valuable in well control situations and live well interventions.

- Precision and Control

Coiled tubing provides exceptional depth control accuracy, typically within ±0.1% of measured depth. This precision enables targeted treatments to specific zones, especially important in complex multilateral or horizontal wells. Real-time downhole data acquisition through fiber-optic or electronic monitoring systems allows for immediate treatment adjustments, optimizing stimulation effectiveness. The technology also permits precise fluid placement during cleanouts or stimulation, minimizing fluid waste and formation damage.

- Economic Benefits

Coiled tubing's smaller footprint and faster mobilization translate to lower operational costs than conventional workover rigs, with shorter job durations meaning minimal production downtime, which helps preserve revenue streams. Furthermore, smaller crews and less equipment typically required make this operation even less costly; additionally performing interventions without killing the well maintains natural reservoir pressure for minimal productivity losses associated with conventional methods.

- Safety and Environmental Benefits

A closed-loop system significantly enhances well control during interventions, minimizing hydrocarbon exposure risks. Smaller fluid volumes are required for operations and therefore, the environmental impact decreases significantly. Furthermore, its technology enables underbalanced operation, which prevents formation damage caused by fluid invasion; additionally,y its reduced equipment footprint means smaller location requirements with reduced surface disturbances.

Coiled tubing systems offer versatile applications across applications, from shallow vertical wells to extended-reach horizontal wells. Their technology supports various intervention types, including cleanouts, stimulations, logging, and perforating; ongoing innovation has expanded capabilities further into through-tubing fishing, milling drilling applications and through tubing fishing/milling applications - making coiled tubing an indispensable tool in conventional as well as unconventional reservoir environments.

Final Thought

Coiled tubing operations play a pivotal role in increasing the efficiency and productivity of oil and gas wells. By employing well intervention and stimulation techniques to maintain and boost production, operators can extend well life while increasing output. Coiled tubing technology continues to evolve as demand for efficient energy solutions increases - thus strengthening its position within well management practices.