How Coiled Tubing Operation Minimizes Environmental Impact

The oil and gas industry is constantly seeking ways to reduce its environmental footprint. Coiled tubing technology offers a promising solution, minimizing environmental impact compared to conventional techniques. This article explores coiled tubing technology, its advantages, and how it contributes to a greener future for the industry.

Understanding Coiled Tubing Technology

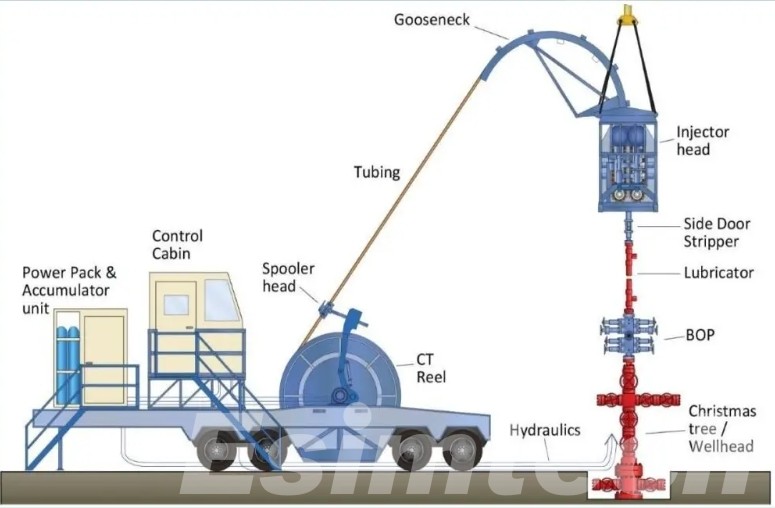

Coiled tubing is a game-changer in well intervention and production. Unlike traditional drilling methods that utilize rigid drill pipe sections painstakingly connected and disconnected, coiled tubing offers a continuous and more efficient approach. Here’s a deeper dive into this innovative technology:

- The Pipe: Coiled tubing is a long, thin metal pipe typically ranging from 1 to 3.25 inches (25 to 83 millimeters) in diameter. This allows for greater flexibility compared to rigid drill pipe, enabling easier deployment into deviated wells with complex geometries. The material is high-strength steel designed to withstand the pressures and stresses encountered downhole.

- Deployment: Coiled tubing is stored on a large reel specifically designed for easy spooling and deployment. During operation, the tubing is fed off the reel through an injector head that guides it into the wellbore. The injector head also provides a pressure seal to prevent leaks.

- Versatility: Coiled tubing’s flexibility and continuous nature make it highly versatile. It can be used for various well interventions, including:

- Well cleaning and stimulation: Coiled tubing can deliver fluids, chemicals, and tools to clean blockages, remove debris, and enhance oil and gas flow.

- Logging and perforating: Sensors and perforating tools can be deployed on coiled tubing to gather valuable data about the wellbore and create perforations to access hydrocarbon zones.

- Workover operations: Coiled tubing can be used for various wellbore maintenance activities, such as replacing downhole equipment or performing repairs.

In essence, coiled tubing acts as a continuous pipeline that can be deployed quickly and efficiently for various well operations, minimizing the need for complex rig setups and multiple interventions.

Environmental Impact of Conventional Techniques

Conventional drilling techniques come with a significant environmental burden. Here’s a closer look at some of the key concerns:

- Habitat Destruction and Land Disruption: Setting up a traditional drilling rig requires a large footprint. This often involves clearing vegetation, excavating land, and building access roads. This disrupts wildlife habitats, contributes to soil erosion, and can fragment ecosystems. The impact is particularly severe in sensitive environments like wetlands, permafrost regions, and areas with unique biodiversity.

- Increased Noise and Air Pollution: Conventional drilling operations involve loud machinery and diesel engines. This generates noise pollution that can disturb wildlife and disrupt human communities living near drilling sites. Additionally, the burning of diesel fuel releases harmful pollutants like nitrogen oxides, particulate matter, and volatile organic compounds (VOCs) into the atmosphere, contributing to smog formation and respiratory problems.

- Drilling Waste Management: Conventional drilling generates large volumes of waste materials like drilling mud, cuttings (rock fragments), and produced water (formation fluids brought up with oil or gas). Improper disposal of these wastes can lead to soil and water contamination. Drilling mud can contain toxic chemicals that harm plants and animals, while produced water can be contaminated with heavy metals, hydrocarbons, and radioactive elements.

- Risk of Spills and Leaks: Conventional drilling operations carry the risk of accidental spills and leaks. These can occur during wellbore construction, transportation of oil and gas, and equipment malfunctions. Spills can contaminate soil and water resources, impacting aquatic ecosystems and posing a threat to human health. Leaks of methane, a potent greenhouse gas, can contribute to climate change.

These are just some of the environmental drawbacks associated with conventional drilling techniques. Coiled tubing technology offers a promising alternative, minimizing these impacts and paving the way for a more sustainable approach to oil and gas production.

How Coiled Tubing Operation Minimizes Environmental Impact

Coiled tubing technology offers a significant advantage over conventional drilling methods when it comes to environmental impact. Here’s a deeper dive into how coiled tubing operations contribute to a greener future for the oil and gas industry:

- Reduced Footprint and Land Disturbance: Conventional drilling rigs are massive, requiring extensive preparation of the well pad. This involves clearing vegetation, leveling land, and constructing access roads. All this activity disrupts natural habitats, increases soil erosion, and can lead to sedimentation in nearby waterways. Coiled tubing rigs, on the other hand, are much smaller and more compact. Their footprint is significantly smaller, minimizing the need for land clearing and associated environmental damage.

- Lower Emissions and Noise Pollution: Large drilling rigs with powerful engines contribute significantly to air pollution through exhaust fumes. Additionally, the drilling process itself generates noise that can disrupt wildlife and disturb nearby communities. Coiled tubing operations utilize smaller rigs with lower fuel consumption, leading to reduced emissions of greenhouse gases and pollutants like nitrogen oxides. The continuous nature of coiled tubing drilling also produces less noise compared to the stop-and-start process of conventional drilling with joint connections.

- Closed-Loop Systems and Waste Reduction: Conventional drilling generates large volumes of drilling mud, a mixture used to cool and lubricate the drill bit and transport cuttings (rock fragments) to the surface. Improper disposal of drilling mud can contaminate soil and water resources. Coiled tubing operations, however, can leverage closed-loop systems. These systems capture and recycle the drilling fluids, significantly reducing waste generation and the risk of spills. The captured fluids can be treated and reused, minimizing the need for freshwater consumption and disposal of contaminated fluids.

- Well Intervention and Enhanced Efficiency: Coiled tubing excels in well intervention procedures like cleaning, stimulation, and downhole tool deployment. These operations can revitalize existing wells, extending their production life and reducing the need for drilling new wells. This translates to a smaller overall environmental footprint as fewer new well pads need to be constructed.

- Sidetrack Drilling and Resource Conservation: In some cases, coiled tubing allows for sidetrack drilling. Here, a new wellbore is created by branching off from an existing well. This eliminates the need for a completely new well pad and associated land disturbance. Additionally, it utilizes existing infrastructure, reducing overall resource consumption.

By minimizing land use, reducing emissions and waste, and promoting well intervention for efficient production, coiled tubing technology offers a vital step towards a more sustainable future for the oil and gas industry.

Esimtech Coiled Tubing Simulator Used for Training

Esimtech, renowned for its excellence in oil and gas simulation software, provides a comprehensive training solution for coiled tubing operations, leveraging both portable and full-sized simulators to accommodate diverse learning needs.

The portable coiled tubing simulator offers operators the flexibility to engage in training exercises virtually anywhere. Its compact design allows for easy transport to various locations, enabling on-site training at well locations or in classroom settings. Despite its portability, this simulator replicates the functionality of full-sized coiled tubing units, providing operators with realistic scenarios to practice equipment operation, procedural workflows, and emergency response procedures.

On the other hand, Esimtech’s full-sized coiled tubing simulators offer immersive, hands-on training experiences in dedicated facilities. These simulators feature authentic replicas of coiled tubing units, control consoles, and simulated wellsite environments. Operators engage in lifelike training scenarios, including simulated downhole conditions, equipment malfunctions, and environmental variables, to develop essential skills and competencies for safe and effective coiled tubing operations.

Both the portable and full-sized simulators are integral components of Esimtech’s training program, offering operators a comprehensive learning experience tailored to their needs. By practicing in controlled environments, operators gain confidence and proficiency in coiled tubing operations while minimizing the risk of accidents or environmental incidents during real-world deployments.

Conclusion

Coiled tubing technology offers a significant step towards a more sustainable oil and gas industry. Its reduced footprint, lower emissions, and closed-loop systems contribute to environmental protection. As coiled tubing technology continues to evolve, it has the potential to play a major role in achieving a cleaner future for energy production.