How Does Matrix Acidizing Work Effectively to Enhance Well Productivity

In the realm of oil and gas extraction, maximizing production from reservoirs remains a constant pursuit. Among the arsenal of techniques employed to achieve this goal, matrix acidizing stands out as a highly effective method for enhancing well productivity. This article explores the principles, process, benefits of matrix acidizing and how simulation technology in the oil and gas industry is used in optimizing and refining the process of matrix acidizing.

Undmatrix acidizingerstanding Matrix Acidizing

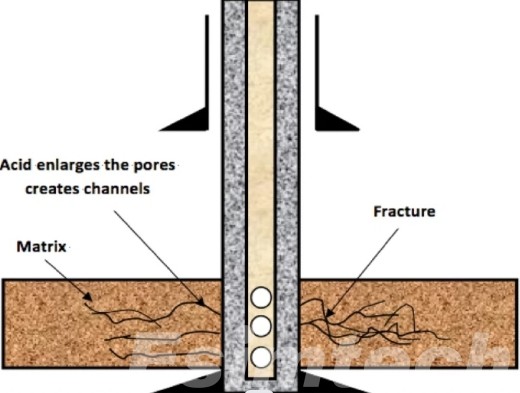

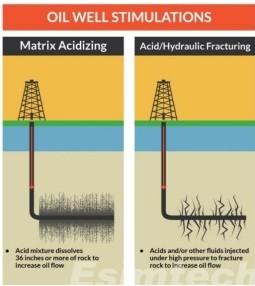

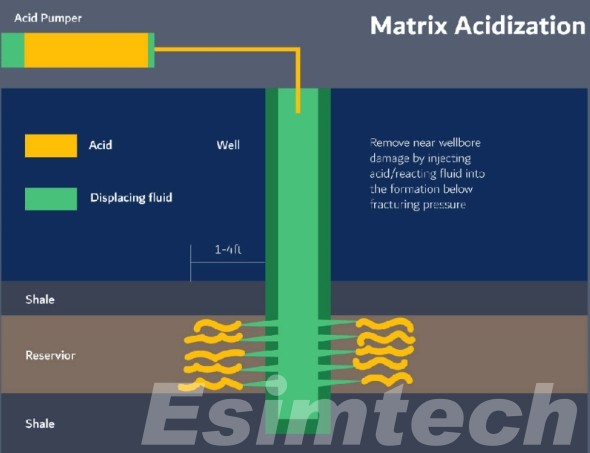

Matrix acidizing is a well stimulation technique that improves the flow of hydrocarbons from reservoir rocks to the wellbore. It entails injecting acid into the formation to dissolve minerals and other elements that impede fluid flow throughout the reservoir matrix. The acid reacts with the rock, forming channels and cracks that enhance permeability and allow oil and gas to flow more readily into the wellbore.

The Process of Matrix Acidizing

1. Reservoir Evaluation

Before initiating matrix acidizing, a thorough evaluation of the reservoir is conducted. This includes analyzing core samples, well logs, and other data to understand the geological characteristics of the formation. The goal is to identify zones with low permeability or formation damage that could benefit from stimulation.

2. Fluid Selection

Acid selection is an important stage in matrix acidizing. The acid used is determined by the composition of the reservoir rock, the temperature, and the required reaction rate. Hydrochloric acid (HCl), organic acids like acetic acid, and acid mixes are all commonly employed in matrix

3. Preparation

Once the suitable acid blend has been determined, the acid is ready for injection. To improve performance and safeguard equipment, dilute the acid with water and add corrosion inhibitors or other chemicals.

4. Injection

The prepared acid blend is pumped downhole into the wellbore at high pressure using specialized pumping equipment. The acid is then driven into the formation via perforations in the well casing, allowing it to travel deep into the reservoir.

5. Acid-Rock Reaction

As the acid comes into contact with the reservoir rock, it initiates chemical reactions that dissolve minerals and other materials blocking pore spaces within the rock matrix. Common minerals targeted for dissolution include calcite, dolomite, and clay particles. The acid creates channels and fractures within the formation, increasing permeability and creating pathways for hydrocarbons to flow more freely to the wellbore.

6. Contact Time

The acid is allowed to react with the reservoir rock for a predetermined period, typically ranging from several hours to a few days. The duration of contact time depends on factors such as the depth of the reservoir, the type of acid used, and the desired extent of stimulation.

7. Flushing and Cleanup

After the acid has had sufficient contact time with the formation, the well is flushed with clean fluid to remove any remaining acid and dissolved materials. This helps prevent corrosion and ensure the integrity of the wellbore and production equipment. The cleanup process may involve pumping fresh water or brine into the well to displace the spent acid and other fluids.

8. Evaluation and Monitoring

Following the acidizing treatment, the well is monitored to assess its response and the effectiveness of the stimulation. Production rates, pressure data, and other parameters are analyzed to determine the impact of the treatment on well performance.

By following these steps, operators can effectively implement matrix acidizing to enhance reservoir productivity and optimize oil and gas production from wells.

Benefits of Matrix Acidizing

1. Improved Permeability

Matrix acidizing increases the permeability of reservoir rocks by dissolving minerals and other materials that restrict fluid flow. This process creates channels and fractures within the formation, allowing oil and gas to flow more freely towards the wellbore.

2. Enhanced Production Rates

By increasing permeability, matrix acidizing can significantly boost production rates from oil and gas wells. The improved flow of hydrocarbons allows operators to extract more resources from the reservoir, leading to higher yields and increased profitability.

3. Cost-Effectiveness

Matrix acidizing is often more cost-effective than other well stimulation techniques, such as hydraulic fracturing. It requires less equipment and resources and can be performed relatively quickly, resulting in lower operational costs and improved economic returns for operators.

4. Versatility

Matrix acidizing can be used on a variety of reservoir types and formations, making it a versatile and adaptable approach for increasing well productivity. It can be customized to suit reservoir conditions and treatment goals, allowing operators to maximize performance in a variety of geological situations.

5. Environmental Benefits

Compared to hydraulic fracturing, matrix acidizing typically requires smaller volumes of fluid and generates less waste. This makes it a more environmentally friendly option for well stimulation, with reduced water usage and minimal surface disturbance.

6. Extended Well Life

Matrix acidizing can help rejuvenate older or underperforming wells by restoring their productivity and extending their operational life. By improving reservoir connectivity and flow pathways, acidizing treatments can revitalize wells that have experienced decline or depletion.

7. Localized Treatment

Matrix acidizing directly targets the reservoir matrix, allowing operators to treat specific zones or intervals of the wellbore. This targeted technique reduces the danger of damage to nearby formations while increasing the treatment's effectiveness.

Simulation Technology Used in Optimizing and Refining the Process of Matrix Acidizing

1. Reservoir Modeling

Engineers can use simulation software to generate detailed 3D models of reservoirs, which include geological data, well logs, and other pertinent information. These models aid in visualizing reservoir structure and features such as permeability, porosity, and fluid saturation, all of which are necessary for planning effective acidizing treatments.

2. Fluid-Rock Interaction Modeling

Simulation tools enable engineers to simulate the chemical reactions between the acid and the reservoir rock at the microscopic level. By modeling the fluid-rock interaction, engineers can predict how different acid formulations will react with specific minerals and materials in the formation, helping optimize acid blend composition and concentration.

3. Flow Simulation

Simulation software can simulate fluid flow within the reservoir during and after acidizing treatments. This allows engineers to predict the distribution of acid within the formation, identify potential flow pathways, and assess the effectiveness of acidizing treatments in improving permeability and enhancing hydrocarbon recovery.

4. Wellbore Modeling

Simulation technology is used to model the wellbore geometry, including casing, perforations, and completion equipment. Engineers can simulate the injection of acid into the wellbore and track its movement through the perforations into the reservoir, ensuring accurate placement and coverage of the acidizing treatment.

5. Treatment Design and Optimization

Simulation tools facilitate the design and optimization of acidizing treatments by allowing engineers to simulate different scenarios and assess their impact on well performance. Engineers can vary parameters such as acid concentration, injection rate, and treatment volume to optimize treatment design and maximize production efficiency.

6. Sensitivity Analysis

Simulation software enables engineers to conduct sensitivity analysis to evaluate the influence of various factors on acidizing performance. This includes assessing the effects of reservoir heterogeneity, fluid properties, and operational parameters on treatment effectiveness, helping identify key variables that impact treatment success.

7. Risk Assessment

Simulation technology is utilized to evaluate the hazards of acidizing treatments, such as formation damage, fluid breakthrough, and other unwanted effects. Engineers can utilize simulation data to create mitigation methods and reduce hazards during treatment implementation.

Conclusion

Matrix acidizing is critical in unlocking the full potential of oil and gas reservoirs by increasing permeability and production rates. In the oil and gas industry, simulation technology is crucial for planning, designing, and executing matrix acidizing treatments. As technology progresses, further innovations in acid formulations and application techniques promise to push the boundaries of reservoir stimulation, resulting in increased efficiency and sustainability in oil and gas production.