Cost Optimization in Oil Drilling

Oil drilling requires a significant investment in exploration, workers, operations, and labor. With the fluctuation of oil prices, volatile global markets, and the growing sustainability requirements, cost optimization has become essential for oil and gas companies to stay competitive while ensuring safe and efficient operations.

Key Drivers of Cost Optimization in Oil Drilling

Market Volatility

It is greatly dependent on fluctuating price of crude, and these directly affect drilling budgets. If prices decrease, operators have to find ways to cut the operational expenses while still delivering. Cost optimization strategies enable businesses to remain competitive during low-cost cycles and increase profitability when prices rebound.

Technological Advancements

New technologies for drilling play an important role in reducing costs. Innovative techniques like directed drilling, controlled pressure drilling, as well as automation cut down on time wasted, improve the accuracy of drilling and prolong the life of equipment. With the help of these tools companies can drill more efficiently and cut down on the amount of drilling required to get access to reserves.

Environmental and Regulatory Pressures

More stringent environmental regulations are pushing businesses to adopt cleaner, more efficient methods. Optimizing operations to reduce emissions, eliminate waste and optimize energy usage does more than ensure compliance but also reduces long-term operating expenses. Reducing the risk of regulatory fines and reputational harm further enhances the financial sustainability of a company.

Operational Efficiency

Inefficient equipment use, and ineffective plan can all lead to increased drilling expenses. By paying attention to proactive maintenance, enhanced supply chain management, as well as automated workflows, operators can increase efficiency. The efficient utilization of resources and labor results in substantial cost savings across all projects.

Key Strategies for Cost Optimization in Oil Drilling

Cost optimization in oil drilling is an effective strategy that helps operators remain competitive, adapt to market fluctuations, and achieve long-term sustainability.

1. Advanced Drilling Technologies

Advanced drilling technologies are important in reducing the overall cost of projects. The horizontal and the directional drills permits access to greater reserves through less wells, which cuts down on the cost of materials and labor. Controlled pressure drilling is a great way to maintain the stability of wellbores, which reduces the risk of accidents and wasting time. These innovative methods allow businesses to do more with less while ensuring security.

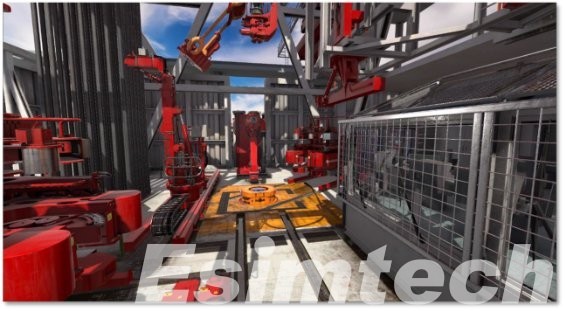

2. Digitalization and Automation

The introduction of electronic tools as well as automated processes has revolutionized cost management for oil drilling. Real-time data analytics allows for better decision-making, more predictive maintenance, and optimization of performance. Robotic rigs and automated rigs make it easier to reduce the need for manual labor, which reduces the cost of workforce while increasing the accuracy and security. Through digitizing workflows, businesses can reduce human errors, improve processes and drastically reduce operational costs.

3. Optimizing Resource Utilization

The efficient management of resources is another important aspect of cost reduction. The careful plan for drilling liquids, casings, and cementing can help reduce the amount of waste and optimize logistics to can reduce the cost of storage and transportation. A streamlined supply chain management system assures that all essential equipment and materials are transported quickly, thus avoiding expensive delays. Effective allocation of resources guarantees that drilling operations are conducted efficiently and with less expense.

4. Improving Well Design and Standardization

Optimization of well design is now an important method to reduce costs. Simulation models enable engineers to test various scenarios and pick the most efficient drilling route. While at the same time uniformizing processes and equipment across projects reduces costs for procurement and streamlines operating and training. When efficiency is prioritized in the design phase, businesses are able to avoid costly expenses in drilling and finalization.

5. Collaborative Contracting Models

Collaboration between oil firms and service providers could result in substantial savings. Performance-based contracts align the motivations of both parties, making sure that service providers get rewarded by boosting efficiency and decreasing expenses. Furthermore, infrastructure projects shared with multiple operators in the same area can help cut down on costs for capital projects and improve the use of resources.

6. Integrating Sustainability for Cost Savings

Sustainable initiatives are now being recognized as cost-saving strategies. Reusing drilling fluids and reducing flaring and utilizing renewable rigs reduce operating costs and energy consumption. Beyond financial advantages they also ensure the compliance of environmental regulations and help improve the company's image on the international energy market.

How Simulation Technologies are Used for Cost Optimization in Oil Drilling

Oil and gas simulation technologies can create virtual models of drilling processes and reservoir conditions, companies can predict outcomes, reduce risks and optimize their operations. This is not just a minimizes costs but also enhances productivity and decision-making across the entire drilling lifecycle.

- Enhancing Well Design Efficiency

One of the biggest applications of simulation technology is in the well design. Engineers can make use of advanced software to design different drilling scenarios, assess reservoir behavior and choose the most efficient drilling route. This helps reduce trial and error on the field, assisting users avoid unnecessary costs and maximizing contact with reservoirs using the smallest number of wells.

- Reducing Non-Productive Time (NPT)

Unplanned downtime is one the biggest cost drivers for oil drilling. Simulation helps operators identify potential problems with drilling such as clogged pipelines, anomalies in pressure or equipment malfunctions, prior to they happen. Through running several scenarios, teams are able to develop contingency plans to reduce the amount of time needed to finish and provide smoother operations and reduce the cost related to NPT.

- Optimizing Drilling Parameters

Drilling simulation systems allow for fine-tuning drilling parameters, such as the weight of the bit as well as rotary speed and the flow rate of mud. By simulated testing these conditions businesses can determine which are the best operating parameters that increase the efficiency of penetration (ROP) while reducing wear and wear on the equipment. This precision results in faster drilling times, less usage of materials, and lower costs overall.

- Improving Training and Workforce Competency

Cost optimization is not just about processes and equipment, but it is also about people. Simulation-based drilling training platforms offer real-world environments for operators and engineers to train without the dangers and expenses of real-world operations. This increases the level of competence of employees decreases human error and provides safe, cost-effective drilling practices on the job.

- Supporting Predictive Maintenance

Simulations can be combined with operational data that is real-time in order to predict the performance of equipment and anticipate failures. This allows operators to plan maintenance in the most optimal time to avoid costly breakdowns and prolonging the life of vital assets. The predictive maintenance based on simulation directly leads to substantial cost savings.

- Facilitating Sustainable Practices

Sustainability and environmental compliance are crucial to optimizing costs. Simulation models enable companies to test eco-friendly drilling fluids, decrease flaring and optimize energy usage in virtual environments prior to applying them on the ground. This helps reduce operating inefficiencies and waste which helps businesses reduce costs while still meeting regulations.

Challenges of Achieving Cost Optimization in Oil Drilling

| Challenge | Description |

| High Upfront Investment | Automation, advanced technologies, and simulation tools require substantial capital investment before savings can be realized. |

| Resistance to Change | The transition from traditional drilling techniques to data-driven, digital methods is often a challenge for both organizational and cultural obstacles. |

| Regulatory Complexity | The different regulations for safety and environmental protection across different regions could make compliance more expensive and complicate the process of optimization. |

| Balanced Safety and Cost Reduction | Saving money should not mean compromising security standards, which could restrict drastic cost-saving measures. |

| Market Volatility | Variable oil prices make it difficult to design long-term optimization strategies consistently. |

| Integration of New Technologies | Implementing new tools and systems involves training, system updates, and adapting times, which temporarily increase the cost. |

Future Outlook of Cost Optimization in Oil Drilling

The future of oil drilling will be shaped by the integration of advanced technologies, sustainable practices and innovative business models that help oil companies to achieve greater efficiency, without sacrificing the safety or environmental responsibility.

Greater Use of Artificial Intelligence and Data Analytics

Artificial Intelligence (AI) along with advanced analytics, is expected to play a growing part in optimizing costs. Through the analysis of huge volumes of drilling data AI systems can detect patterns, predict failures of equipment and suggest the most efficient drilling parameters. This level of accuracy will cut down on time lost to production and reduce wear on equipment and reduce operational costs.

Expansion of Digital Twins and Simulation

Digital twins, virtual replicas of drilling operations and assets are predicted to become standard tools within the industry. They allow operators to evaluate scenarios, predict problems, and improve efficiency in an virtual world before implementing strategies on the ground. As the technology of simulation improves, they will reduce the need for trial and error cost, while also improving drilling precision.

Adoption of Modular and Mobile Drilling Rigs

The future of cost-saving will be dependent on a more adaptable infrastructure. Mobile and modular rigs, which are more convenient to move and put together, can reduce the cost of setup and increase operational efficiency. This flexibility will be particularly beneficial in challenging or remote drilling conditions where conventional drilling equipment is expensive to set up.

Sustainability as a Core Strategy

Sustainability will move from being a requirement for compliance to an integral part in cost control. Methods like recycle drilling fluids, decreasing flaring and incorporating renewable energy sources in drilling operations will not only reduce environmental impacts but also provide long-term savings. Companies that incorporate sustainability into their cost plans will benefit both financially and reputational benefits.

Strengthened Collaboration and Contracting Models

Future drilling projects could require stronger partnerships between service providers, operators and companies in the field of technology. Shared infrastructure and performance-based contracts projects will bring incentives in line and help reduce capital expenditures overall. Collaboration models ensure that cost optimization benefits are shared across every step of the supply chain.

Summary

Cost optimization in oil drilling involves adopting innovative strategies that enhance efficiency and sustainability. Through the use of advanced technologies, improving well design and fostering collaborative business models, Oil and gas companies can navigate market volatility while securing long-term operational drilling success.