Drilling Simulators-Enhancing Efficiency In The Oil And Gas Industry

Drilling simulators have emerged as a valuable instrument for improving drilling efficiency and safety. This article will provide a comprehensive overview of drilling simulators, including their components, benefits, development trend, etc.

What Are Drilling Simulators

Drilling simulators are training systems that simulate drilling operations, giving trainees practical, real-world experience without the risks and expenses of actual drilling. Their primary objective is to improve the efficiency and safety of drilling activities. Simulators reduce the risks connected with actual drilling by providing trainees with realistic drilling experiences while also lowering the costs of tools, personnel, and downtime.

Virtual drilling simulators

Virtual drilling simulators are computer-based systems that enable trainees to practice drilling operations in a simulated setting. They simulate the drilling rig and tools, as well as the drilling processes and environment, to provide a realistic and immersive training experience. Virtual drilling simulators offer several advantages over physical simulators, such as reduced costs, the ability to simulate more complex drilling scenarios, and the ability to monitor and analyze trainee performance data.

Components Of drilling simulators

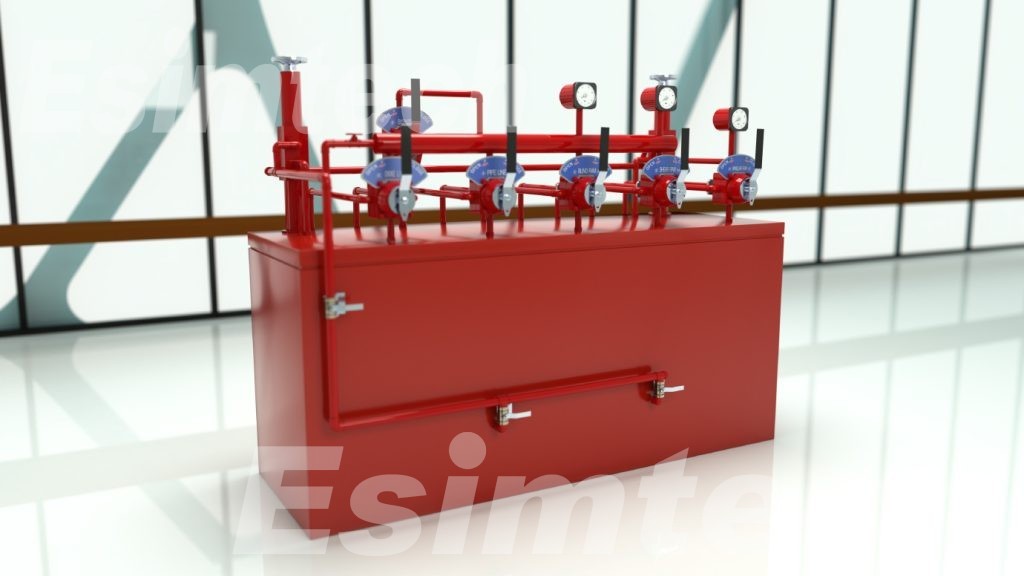

Drilling simulators are made up of both physical and software components. The drilling rig, control systems, and sensors are examples of hardware, while simulation models, visualisation tools, and data analyses are examples of software. Although the drilling rig and equipment are typically scaled-down versions of real drilling equipment, they must accurately replicate the functionality and behaviour of the actual equipment. The simulation models are computer programmes that simulate drilling physics and equipment behaviour.

Why Choose Drilling Simulators In The Oil And Gas Industry

Drilling simulators are extensively used for training purposes in the oil and gas industry. They help to train drilling crews, better drilling operations, and increase safety. They can be used to model a variety of drilling scenarios, including harsh environment drilling, deepwater drilling, and unconventional drilling. Simulators can also be used to evaluate drilling equipment efficiency and optimise drilling processes.

Advantages Of Using Drilling Simulators

Drilling simulators offer several benefits, including expense savings, better safety, increased training efficiency, and realistic simulations. Simulators reduce the risks connected with actual drilling by providing trainees with realistic drilling experiences while also lowering the costs of tools, personnel, and downtime. Simulators also provide a safe setting in which trainees can make mistakes and learn from them without putting themselves or others in danger. Finally, simulators can be used to replicate a wide range of drilling situations, from routine operations to complex and hazardous operations, giving trainees a diverse range of experience.

Development Trends Of Drilling Simulators

Drilling simulator development is constantly evolving, with several patterns emerging. Virtual reality is becoming more popular, offering a more immersive training experience. Virtual reality simulators enable trainees to engage in real time with simulated environments and equipment, enhancing their training experience. They are increasingly being integrated with automation technology, which improves the effectiveness of drilling operations. Drilling systems that are automated can be controlled and monitored from a remote place, reducing the need for on-site personnel. Drilling data is also analysed and drilling operations are optimised using advanced data analytics. Drilling crews can use data analytics to spot patterns and trends in drilling data, enabling them to optimise drilling processes and reduce drilling costs.

Conclusion

Drilling simulators are an important tool in the oil and gas industry for increasing the efficiency of drilling operations. They provide realistic drilling experiences for trainees, lower risks and costs, and enable drilling crews to practise a variety of drilling scenarios. Drilling simulator development is constantly changing, with the incorporation of virtual reality, automation technology, and data analytics.