ERD Drilling vs. Conventional Drilling: A Cost-Benefit Analysis

The quest for oil and gas resources often demands innovative solutions. Extended Reach Drilling (ERD) and conventional drilling are two prominent methods, each with distinct advantages and disadvantages. This article delves into the cost considerations and benefits of ERD drilling and Conventional drilling, aiding you in making informed decisions for your drilling project.

Extended Reach Drilling and Conventional Drilling

While conventional drilling offers a well-understood and direct approach, ERD drilling unlocks previously inaccessible reserves, presenting both unique challenges and opportunities.

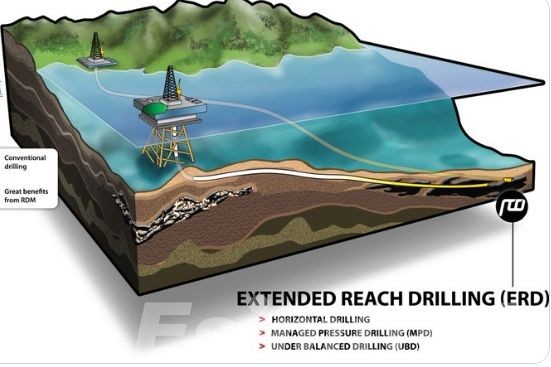

Extended Reach Drilling (ERD)

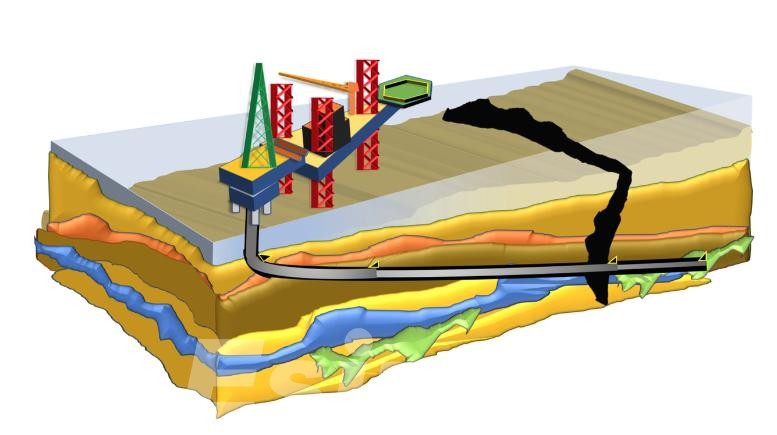

ERD is a sophisticated drilling technique that deviates significantly from vertical, enabling wellbores to extend for kilometers laterally, reaching reservoirs far from the drilling platform. This method can be likened to navigating a complex subterranean labyrinth. Specialized drilling rigs equipped with advanced downhole steering tools are employed to achieve precise control over the wellbore trajectory. These tools, such as downhole mud motors or rotary steerable systems, meticulously guide the drill bit in the desired direction, allowing for meticulous navigation through challenging geological formations. Maintaining wellbore stability at such extreme inclinations necessitates the utilization of specialized drilling fluids. These engineered fluids are formulated to manage pressure effectively, cool the drill bit efficiently, and facilitate the transportation of drill cuttings back to the surface. While ERD represents a marvel of engineering ingenuity, its inherent complexity translates to higher upfront costs.

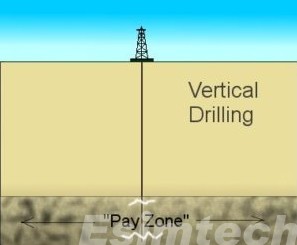

Conventional Drilling

Conventional drilling, in contrast, represents the established and reliable method. It involves drilling a wellbore that is predominantly vertical, or with minimal deviation from vertical. This method can be envisioned as a straightforward approach, drilling a direct path down to the target reservoir. Conventional drilling boasts a well-established infrastructure, with readily available and familiar rigs and equipment. The drilling process itself is relatively uncomplicated, making it a cost-effective solution for readily accessible targets. Conventional drilling rigs are simpler in design and less expensive to operate compared to the sophisticated rigs required for ERD. Additionally, due to the direct path to the reservoir, drilling times are typically shorter with conventional methods.

Cost Considerations in ERD vs. Conventional Drilling

The allure of accessing previously unreachable reserves with ERD comes at a price. Here’s a deeper dive into the cost considerations that differentiate these drilling methods:

- Rig Mobilization and Operation: ERD rigs are specifically designed for directional drilling. These complex machines require specialized crews and carry a higher price tag for both mobilization and daily operation compared to conventional rigs.

- Drilling Time: Drilling a wellbore that extends for miles at an angle is inherently slower than drilling a straight well. This translates to increased rig time and associated costs for crew, equipment, and consumables like drill bits that experience higher wear and tear in ERD operations.

- Wellbore Complexity: Maintaining wellbore stability while drilling at an angle presents additional challenges. ERD necessitates specialized tools like mud motors and downhole stabilizers to ensure the wellbore stays on course and avoids collapse. These additional tools add to the overall cost.

- Drilling Fluids: ERD relies on specially formulated drilling fluids that can handle the higher pressures and temperatures encountered while drilling at an angle and over longer distances. These advanced mud systems can be significantly more expensive than those used in conventional drilling.

- Data Acquisition and Monitoring: Precise wellbore placement is crucial for ERD success. This necessitates the use of advanced downhole logging tools and real-time drilling data monitoring systems, leading to additional costs compared to the simpler data acquisition needs of conventional drilling.

- Waste Management: While ERD may require fewer well locations, the extended wellbore length can generate a larger volume of drill cuttings. Disposing of this waste according to environmental regulations can add to the overall project cost.

Benefits Analysis in ERD vs. Conventional Drilling

While EDR drilling methods appear to require higher costs, there are potential benefits.

- Reservoir Access: ERD is the game-changer for accessing reserves unreachable by conventional drilling. It allows you to tap into deposits located beneath environmentally sensitive areas, undersea formations, or beneath existing infrastructure. This opens up entirely new exploration possibilities, extending the life of mature fields and unlocking resources previously deemed out of reach.

- Reduced Platform Footprint: Imagine drilling multiple wells from a single platform instead of requiring a separate platform for each well. This is the power of ERD. By enabling directional drilling over long distances, ERD minimizes the environmental impact associated with multiple drilling sites. Additionally, it optimizes production by concentrating wellbores in a smaller area, leading to more efficient management and infrastructure needs.

- Improved Recovery Rates: Conventional drilling often relies on a single wellbore to drain a reservoir. ERD, however, allows for precise wellbore placement within the reservoir. This targeted approach can significantly enhance reservoir drainage, leading to higher oil and gas recovery rates. By maximizing the amount of recoverable resources, ERD can significantly increase the project’s overall profitability.

- Reduced Seismic Surveys: ERD’s ability to navigate complex geological formations can sometimes eliminate the need for extensive seismic surveys. Seismic surveys, while crucial for exploration, can be expensive and time-consuming. By using ERD to target specific areas based on existing geological data, companies can potentially save significant resources on exploration activities.

Conclusion

The choice between ERD drilling and conventional drilling hinges on a thorough cost-benefit analysis. While ERD presents higher upfront costs, its ability to access difficult reserves and potentially recover more resources can lead to significant long-term gains. Conversely, conventional drilling offers a cost-effective solution for readily accessible targets.