What are the Latest Developments in Extended Reach Drilling and How is Simulation Technology Used in It

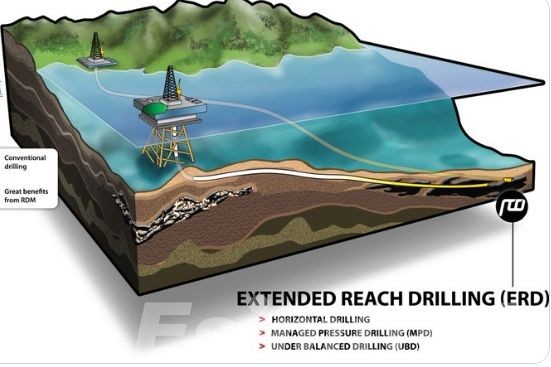

Extended-reach drilling (ERD) has transformed the oil and gas industry, allowing operators to tap into previously inaccessible sources. ERD drilling has advanced significantly in recent years, transforming the oil and gas sector by providing access to hitherto undiscovered sources. These developments have not only expanded the reach of drilling operations but have also improved efficiency, reduced costs, and minimized environmental impact. In this article, we will explore the latest advancements that are reshaping the landscape of extended-reach drilling and how simulation technology is used to enhance the performance of ERD drilling.

Understanding Extended Reach Drilling

1. Definition and Purpose

| Aspect | Description |

| Definition: | A kind of advanced drilling techniques designed to reach reservoirs located at extended lateral distances from the drilling point. |

| Purpose: | Maximize hydrocarbon recovery by accessing distant or challenging reservoirs from a single wellbore. |

2. Key Components and Techniques

| Component/Technique | Description |

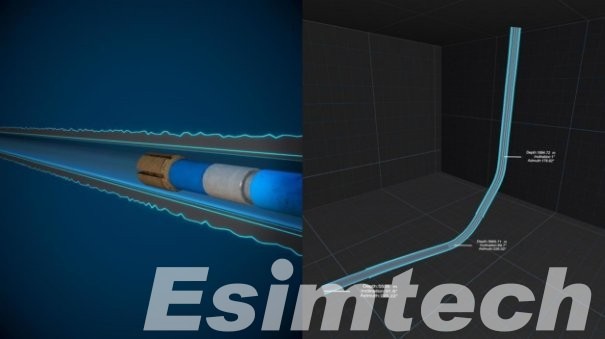

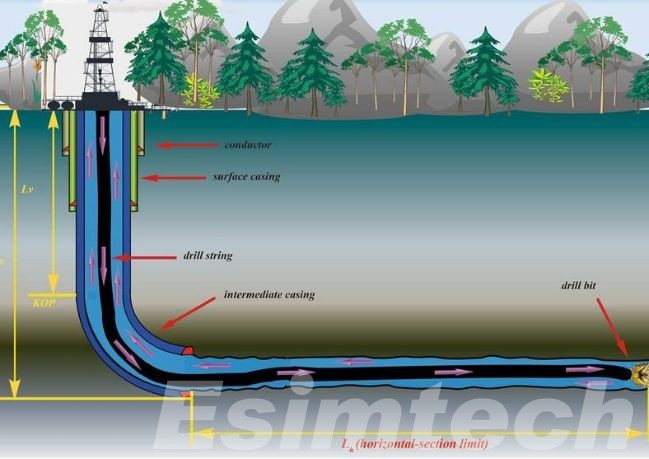

| Bent Sub Technology: | Integration of bent sub-assemblies to change the well trajectory, enabling horizontal drilling at extended distances. |

| Rotary Steerable Systems: | Use of advanced drilling tools that can adjust the wellbore trajectory while drilling, enhancing directional control. |

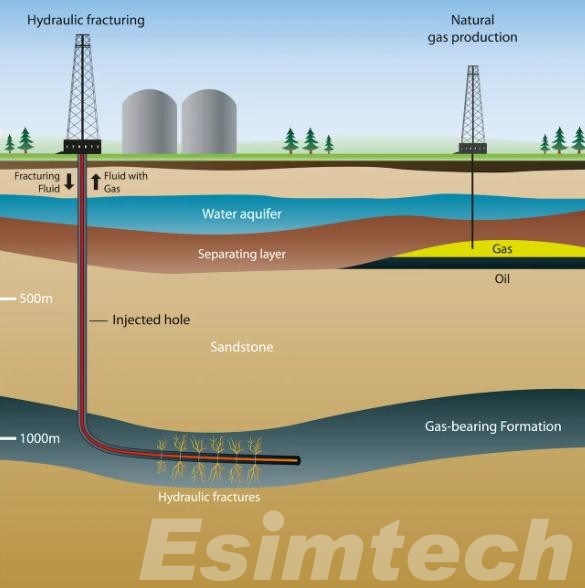

| Managed Pressure Drilling: | Implementation of techniques to control and manage wellbore pressure in challenging drilling environments. |

3. Benefits of Extended Reach Drilling

| Benefits | Description |

| Maximized Reservoir Contact: | Allows for extensive coverage of reservoirs, increasing the contact area and improving hydrocarbon recovery. |

| Reduced Environmental Footprint: | Minimizes the need for multiple wellbores, reducing the environmental impact and surface footprint. |

| Cost Efficiency: | Enables cost savings by reaching multiple reservoirs from a single drilling site, and optimizing resources. |

Latest Advancements in Extended Reach Drilling

1. Drilling Rig Innovations

Modern drilling rigs have undergone significant modifications, increasing their capability for long reach drilling. Advanced rig designs include features like increased load capacity, improved stability, and enhanced automation. Automated pipe-handling systems and sophisticated drilling controls help rigs tackle the difficulties of extended-reach wells, resulting in smoother and more efficient drilling operations.

2. Advancements in Drill Bits

Drill bit technology has advanced tremendously, solving the challenges of drilling long-reach wells across varying formations. Material, cutting structure, and design innovations have resulted in drill bits that are more durable and efficient. PDC (Polycrystalline Diamond Compact) bits, for example, provide increased durability and cutting efficiency, allowing for higher penetration rates in difficult geological settings.

3. Rotary Steerable Systems (RSS)

Rotary steerable systems have become essential for extended-reach drilling. These technologies give real-time control over well paths, enabling precise modifications during drilling operations. The latest RSS technologies provide higher dependability, reactivity, and the capacity to explore complex well profiles more accurately.

4. Enhanced Downhole Technologies

Downhole tools and sensors have seen substantial advances, allowing for more efficient data collecting and analysis during drilling. Advanced Logging-While-Drilling (LWD) and Measurement-While-Drilling (MWD) tools provide real-time information about the subsurface geology, enabling drillers to make informed decisions on the fly. This real-time data enhances well placement accuracy and reduces the risks associated with extended-reach drilling.

5. Geosteering and Formation Evaluation

Geosteering technology has advanced to optimize wellbore placement in real-time. Drillers can use advanced software solutions to navigate difficult geological formations, reducing the likelihood of meeting drilling obstacles. Integration with formation evaluation tools allows for continuous assessment of the reservoir’s properties, aiding in maximizing hydrocarbon recovery.

6. Digitalization and Data Analytics

The industry has embraced digitalization, leveraging big data and analytics to improve decision-making in extended-reach drilling projects. Predictive analytics help forecast potential challenges, optimize drilling parameters, and enhance overall operational efficiency. Digital twins, virtual replicas of the drilling system, enable real-time monitoring and simulation, providing valuable insights for better decision-making.

7. Environmental Considerations

As environmental sustainability becomes a focal point, extended-reach drilling has adapted by implementing eco-friendly practices. The use of biodegradable drilling fluids, reduced emissions through advanced rig designs, and the incorporation of renewable energy sources contribute to minimizing the environmental impact of drilling operations.

8. Offshore Extended Reach Drilling

Offshore drilling has made considerable advances in extended reach capabilities. Innovations in rig design, subsea technologies, and remotely operated vehicles (ROVs) have allowed operators to explore and utilize offshore reserves more effectively. This is especially important because offshore areas can provide unique problems in terms of accessibility and environmental conditions.

Simulation Technology Used in Extended Reach Drilling

Extended-reach drilling (ERD) operations benefit greatly from simulation technology, which allows drilling engineers to examine, simulate, and improve numerous parts of the drilling process. Advanced simulation tools have become an essential aspect of planning and performing ERD operations, providing insights into wellbore behavior, geomechanics, and overall drilling performance.

1. Advanced Drilling Simulators

| Technology | Description |

| 3D Visualization: | Realistic 3D models of wellbores and environments. |

| Real-Time Data Integration: | Integration of real-time data for accurate drilling simulations. |

| Dynamic Wellbore Modeling: | Dynamic modeling considering tool interactions and wellbore stability. |

2. Drilling Process Simulation

| Simulation Type | Description |

| Torque and Drag Simulation: | Simulating mechanical forces for optimal drillstring design. |

| Hydraulic fracturing Simulation: | Modeling fluid flow dynamics for mud and fluid property optimization. |

| Bit-Formation Interaction: | Simulating drilling bit interaction with the formation for improved performance. |

3. Virtual and Augmented Reality Integration

| Integration Aspect | Benefits |

| Immersive VR Environments: | Realistic virtual environments for training and scenario analysis. |

| AR for Real-Time Information: | Real-time information overlays for enhanced decision-making during drilling. |

4. Training Simulations

| Training Aspect | Description |

| Driller Training Simulators: | Risk-free simulations for training drillers in various scenarios. |

| Crew Coordination Simulations: | Simulating coordination and communication among drilling crew members. |

5. Geomechanics and Formation Simulation

| Simulation Type | Description |

| Rock Mechanics Modeling: | Simulating mechanical behavior of rocks to predict wellbore stability. |

| Formation Pressure Prediction: | Modeling changes in formation pressure for accurate well control. |

6. Integration with AI and Machine Learning

| Integration Aspect | Benefits |

| Automated Decision Support: | AI for real-time decision support based on simulation data. |

| Predictive Analytics: | Machine learning predicts drilling challenges and optimizing parameters. |

7. Drilling System Optimization

| Optimization Aspect | Description |

| Parameter Optimization: | Optimizing weight on bit, rotation speed, and flow rates for efficiency. |

| Cost-Benefit Analysis: | Analyzing cost implications of different drilling strategies and equipment configurations. |

Conclusion

The latest developments in extended-reach drilling demonstrate a combination of innovative technologies, intelligent data analytics, and a commitment to environmental sustainability. Collectively, these improvements help to make extended reach drilling more efficient, cost-effective, and environmentally friendly, opening up new opportunities for hydrocarbon exploration and production.

Simulation technology has become a valuable asset in the field of extended reach drilling.

Simulators enable engineers to optimize well trajectories, increase drilling efficiency, and reduce hazards associated with complicated drilling projects by giving a thorough understanding of the drilling environment. As technology advances, the integration of simulation tools with real-time data analytics is anticipated to become even more important in the success of extended reach drilling operations.